RWB 6104 WMNX Page 9

Verify that the air tube installed on the burner

provides the correct insertion depth. See

Figure 4.

The end of the air tube should normally be ¼”

back from the inside wall of the combustion

chamber. Never allow the leading edge of the

head assembly to extend into the chamber,

unless otherwise specifi ed by the heating

appliance manufacturer. Carefully measure

the insertion depth when using an adjustable

fl ange. Verify the insertion depth when using a

welded fl ange.

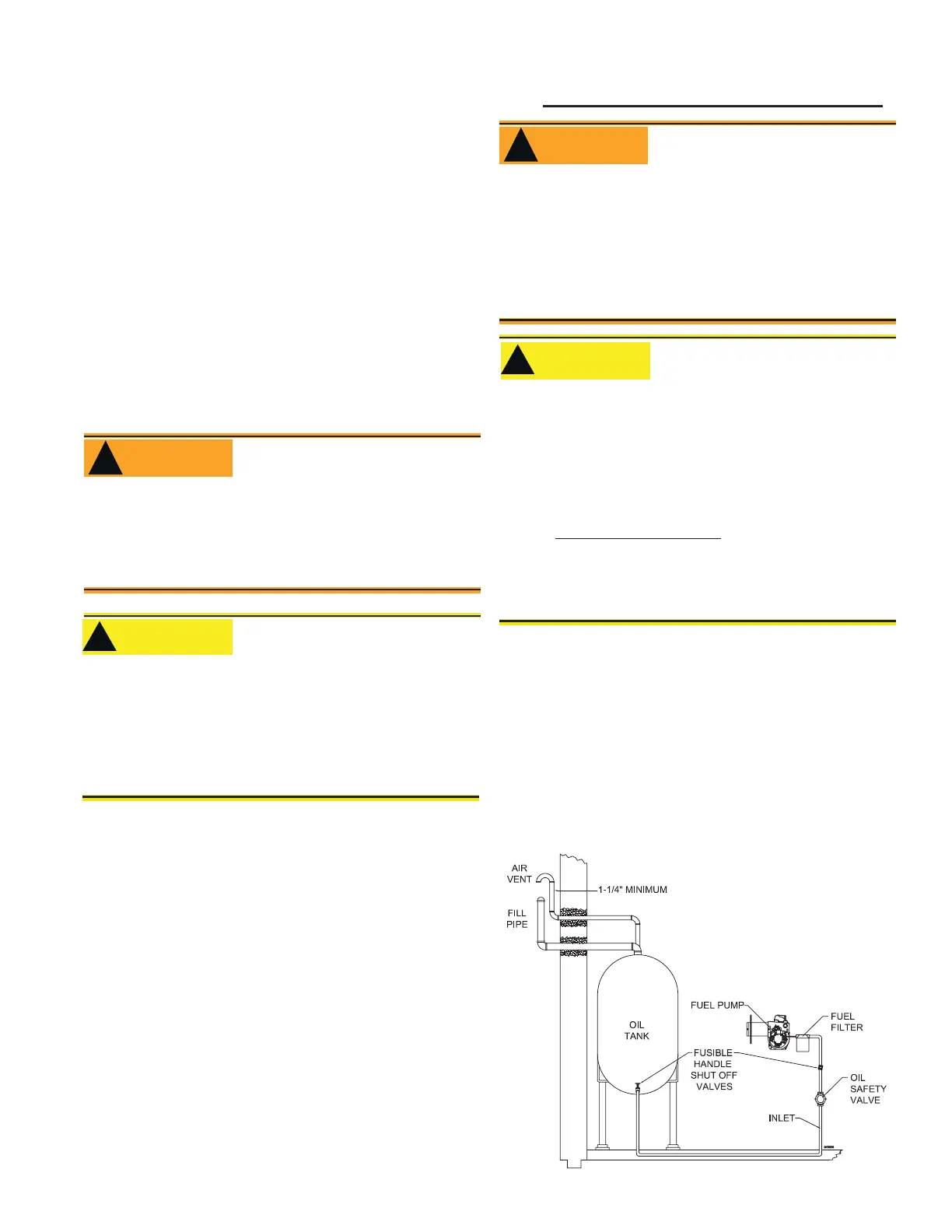

Installing the Oil Tank and Supply Sys-

tem

2.

3.

•

Note: to determine the proper fuel line size, refer

to the fuel pump manufacturer’s instructions pro-

vided with the burner. Refer to Figure 5 or Figure 6

for typical installation layouts.

Fuel Line Valves and Filter

Install two high quality, oil duty rated, fusible

handle design shutoff valves in accessible loca-

tions on the oil supply line. Locate one close to the

tank and the other close to the burner, upstream of

the fi lter for service access.

Install a generous capacity fi lter inside the building

between the fuel tank shutoff valve and the burner,

locating both the fi lter and the valve close to the

burner for ease of servicing. Filter should be rated

for 50 microns or less.

Fuel supply level with or above burner

•

The burner is shipped without the by-pass plug in-

stalled.

Install the by-pass plug in two-pipe oil supply systems

ONLY.

•

•

Failure to comply could cause immediate pump

seal failure, pressurized oil leakage and the po-

tential for a fi re and injury hazard.

Do Not Install By-pass Plug

with 1-Pipe System

WARNING

!

The oil supply inlet pressure to the burner cannot

exceed 3 psig.

Insure that a pressure limiting device is installed

in accordance with the latest edition of NFPA 31.

Do NOT install valves in the return line.

Gravity Feed Systems: Always install an anit-

siphon valve in the oil supply line or a solenoid

valve (RWB Part # 2182602U) in the pump/noz-

zle discharge tubing to provide backup oil fl ow

cut-off protection.

•

•

•

•

Damage to the fi lter or pump seals could cause

oil leakage and a fi re hazard.

Oil Supply Pressure

Control Required

!

CAUTION

Never use Tefl on tape on fuel oil fi ttings.

Tape fragments can lodge in fuel line components

and fuel unit, damaging the equipment and pre-

venting proper operation.

Use oil-resistant pipe sealant compounds.

•

•

•

Damage to the pump could cause impaired burn-

er operation, oil leakage and appliance soot-up.

Do Not Use Tefl on Tape

!

CAUTION

Oil Leak and Fire Hazard

WARNING

!

Install the oil tank following applicable stan-

dards in the U.S. by referring to the latest

edition of NFPA 31 or CSA-B139 & CSA-B140

in Canada, and all authorities having jurisdic-

tion.

Figure 5. – Inside Tank Gravity Feed System

The burner may be equipped with a single-stage

fuel unit for these installations. Connect the fuel

supply to the burner with a single supply line if you

want a one-pipe system (making sure the bypass

plug is NOT installed in the fuel unit.) Manual

bleeding of the fuel unit is required on initial start-

up. If connecting a two-pipe fuel supply, install the

fuel unit bypass plug.

Loading...

Loading...