Description

TF5200 | TwinCAT 3 CNC

Online tool compensation

28 Version: 1.02

2.7.2 Axis-specific connection

The build-specific definitions apply to the following descriptions of the control units:

CNC Version >= V2.11.2800:axis_idx = [0..HLI_SYS_AX_MAXIDX]

CNC Version <V2.11.2800:axis_idx = [1.. HLI_SYS_AXMAX]

2.7.2.1 Adding wear in axis direction

The interface can be used with both for RADIUS or LENGTH processing types. The mode must be DISC or

AUTO.

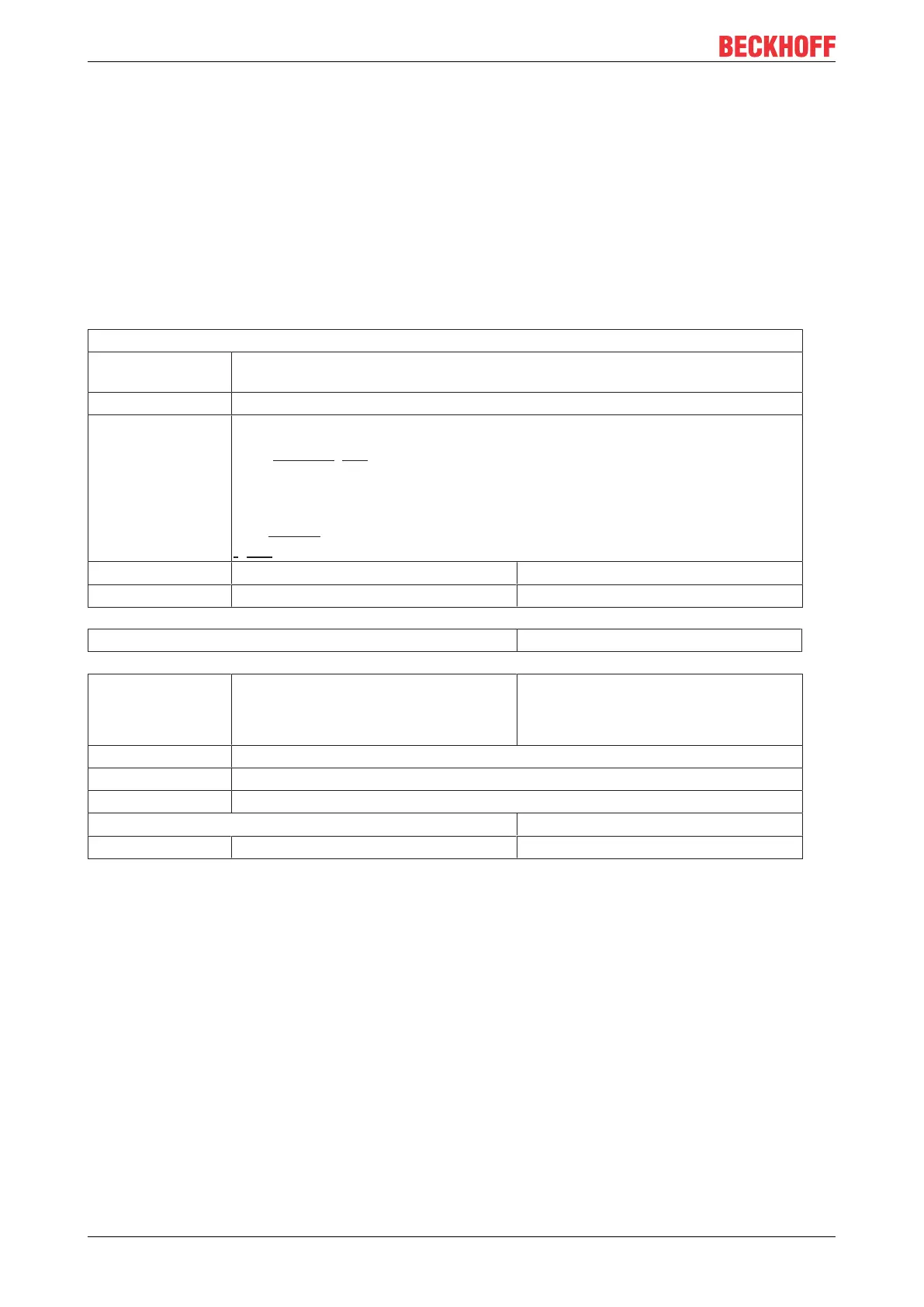

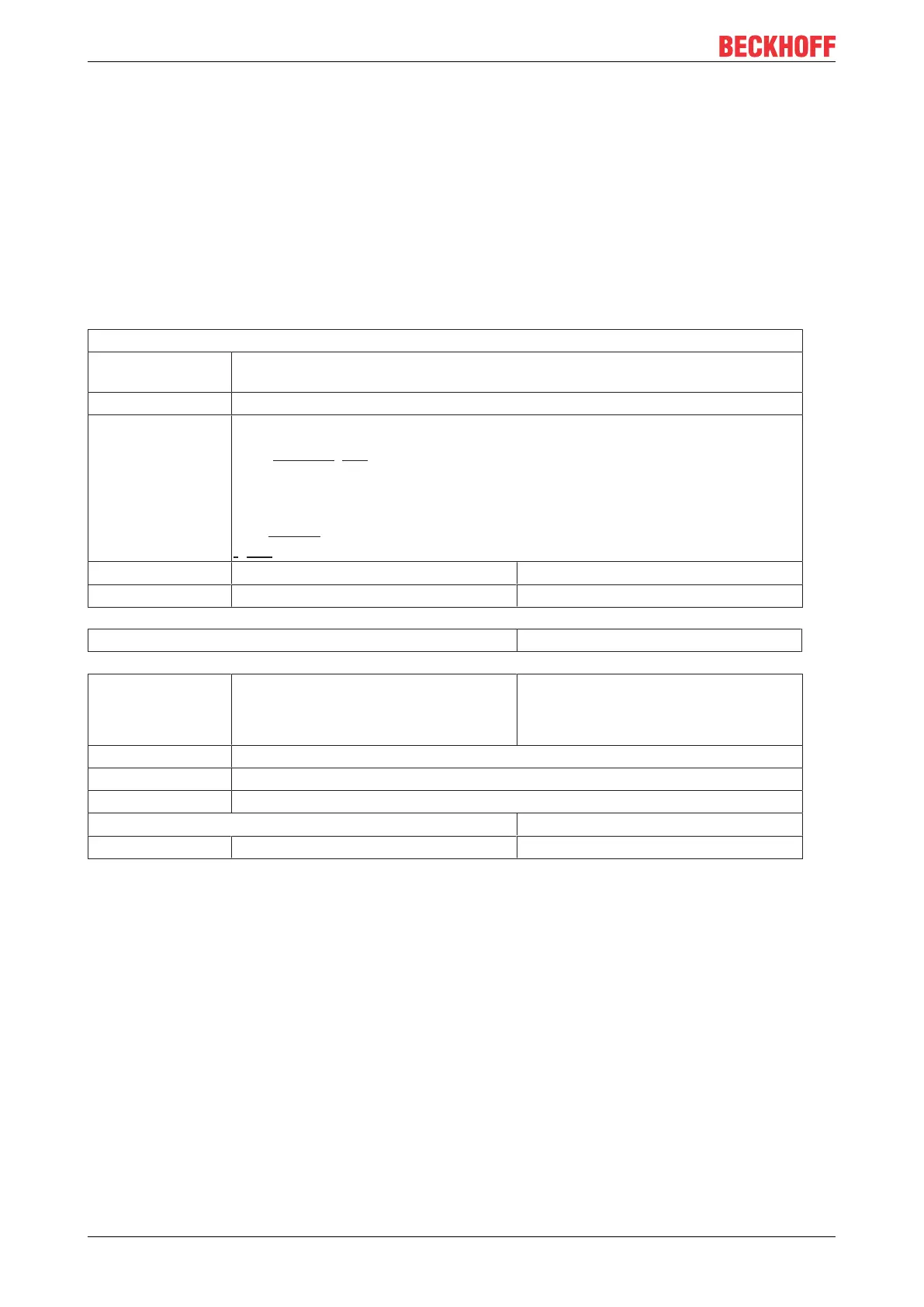

OTC offset

Description When this wear offset is set, wear in the direction of this axis can be

compensated.

Special features The wear offset is distributed by the CNC over several cycles.

ST path CNC Version >= V2.11.2800:

gpAx[axis_idx [}28]]^.ipo_mc_control.otc_offset

CNC Version < V2.11.2800:

pAC[axis_idx

[}28]]^.addr^.McControlIpo_Data.MCControlSGN32Unit_OTCOffset

CNC build >= V2.11.2800 < V2.11.2800

Data type MC_CONTROL_SGN32_UNIT MCControlSGN32Unit

Commanded, requested and return value

ST element .command_w

.request_r

.state_r

.D_Command

.D_Request

.D_State

Data type DINT

Unit 0.1 µm

Value range [-P-TOOL-00031, P-TOOL-00031]

Redirection

ST element .enable_w .X_Enable

Loading...

Loading...