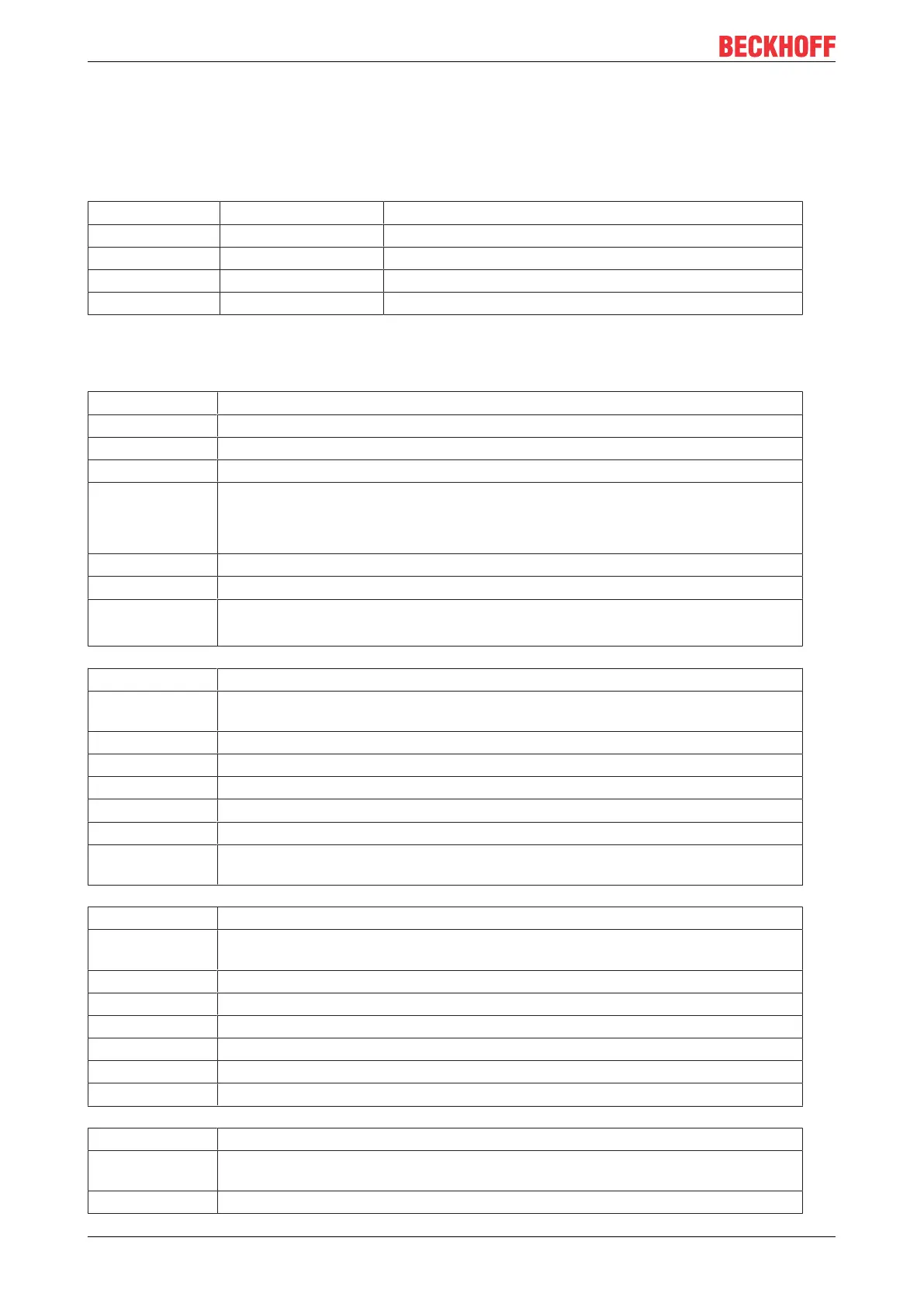

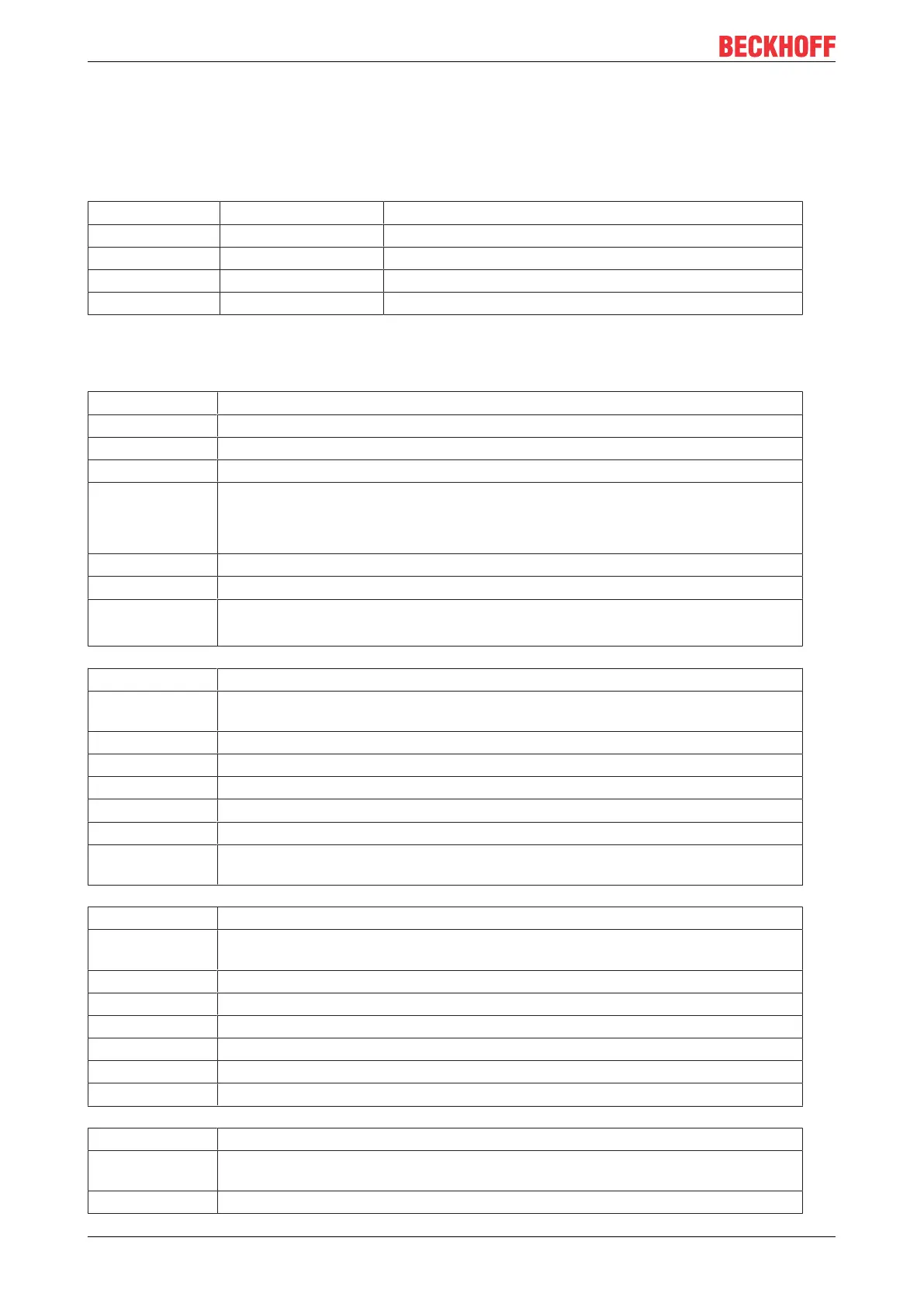

Parameter

TF5200 | TwinCAT 3 CNC

Online tool compensation

32 Version: 1.02

3 Parameter

3.1 Overview

ID Parameter Description

P-TOOL-00001 typ Tool type

P-TOOL-00030 grinding_wear_const Wear constant

P-TOOL-00031 grinding_max_infeed Maximum discrete input

P-TOOL-00032 grinding_tilt_angle Grinding disc tilt angle

3.2 Description

P-TOOL-00001 Type

Description This parameter is assigned to distinguish between tool types.

Parameter wz[i].typ

Data type UNS16

Data range 0: Milling tool

1: Turning tool

2: Grinding tool

Dimension ----

Default value 0

Remarks Parameterisation example: Tool 5 is a milling tool

wz[5]typ 0

P-TOOL-00030 Wear constant

Description The wear constant is used to calculate continuous tool wear. Alternatively, it can

also be defined in the NC program (#OTC […].

Parameter wz[i].grinding_wear_const

Data type REAL64

Data range 0 ≤ grinding_wear_const

Dimension 0.1µm/m

Default value 0

Remarks The wear constant should contain relatively small values. There is no special

dynamic consideration based on the actual wear values.

P-TOOL-00031 Maximum discrete infeed

Description The maximum discrete infeed defines the greatest relative change which is

assignable by the PLC.

Parameter wz[i].grinding_max_infeed

Data type REAL64

Data range MIN(SGN32) ≤ grinding_max_infeed ≤ MAX(SGN32)

Dimension 0.1µm

Default value 0

Remarks

P-TOOL-00032 Grinding disc tilt angle

Description The parameter defines the angle between the centre line of the grinding disc and the

3rd main axis for tilted grinding discs.

Parameter wz[i].grinding_disc_tilt_angle

Loading...

Loading...