June 2004 9507EM/5

2-27

2 to 9 Tonne Dumper Instruction Manual

Maintenance

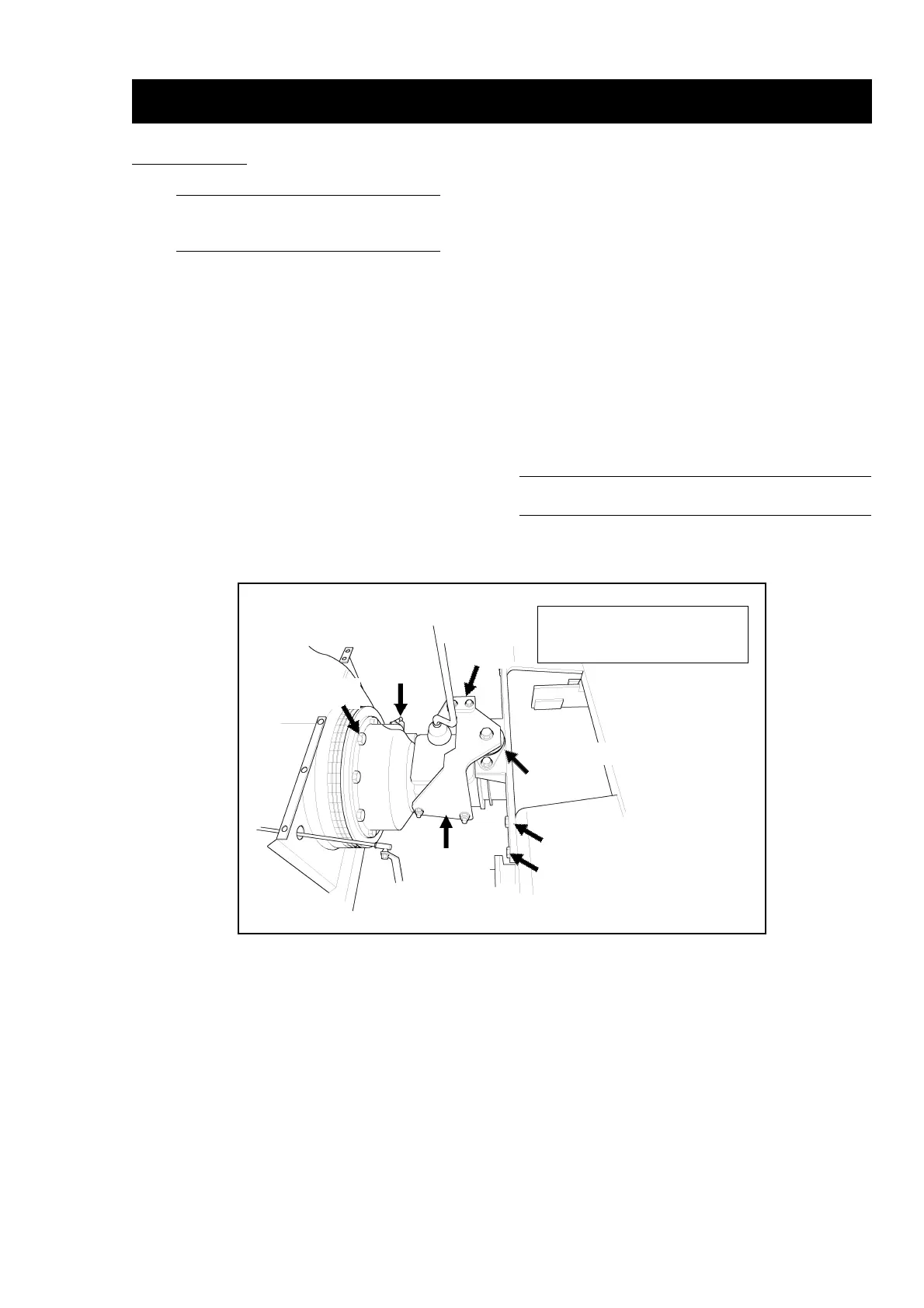

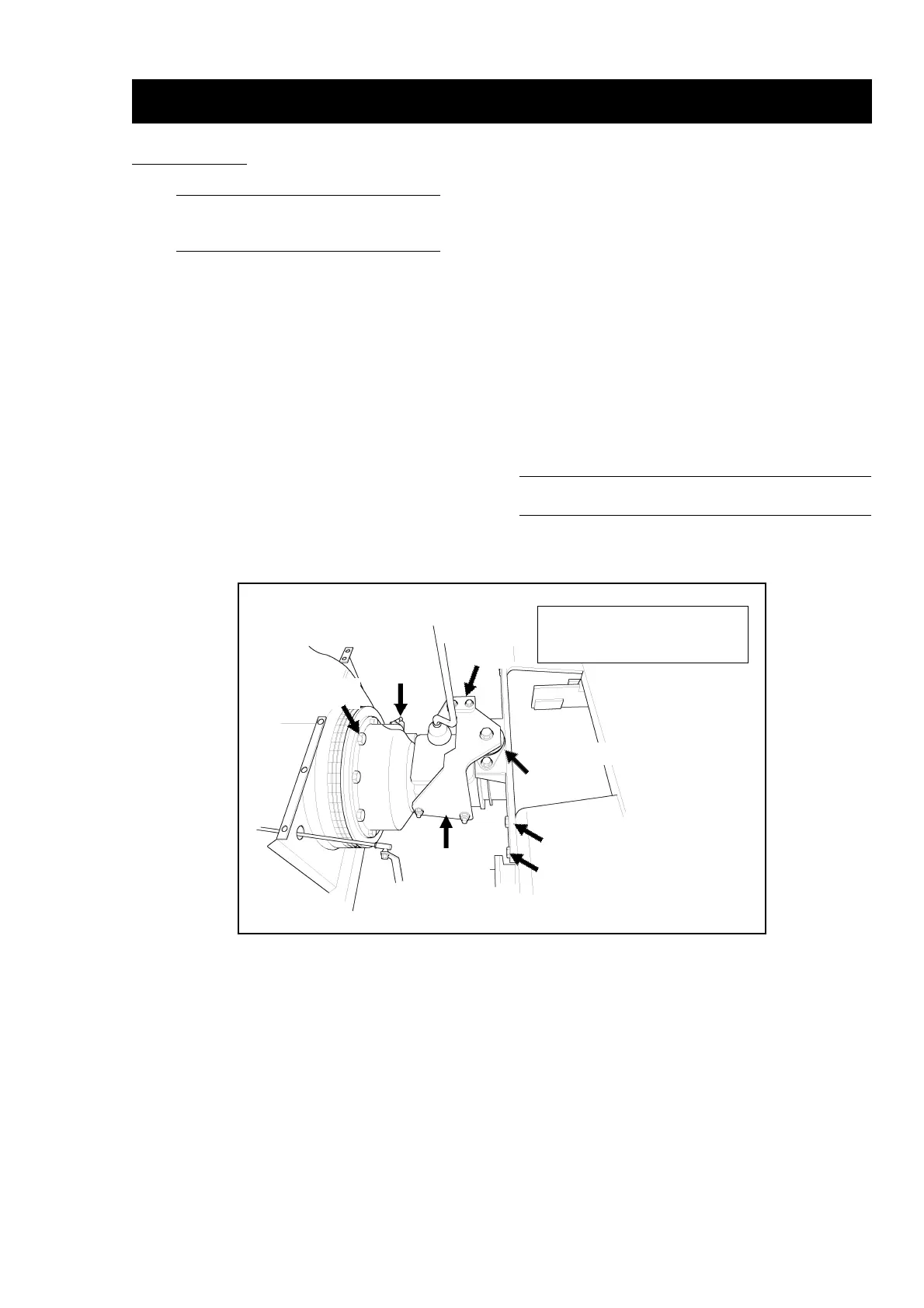

Clutch

Operating

Arm

A.V. Mount

Bell Housing

Setscrews

A.V. Mount Crossmember

A.V. Mount Crossmember

Fixings - Two Either End

Right Hand

Gearbox Side

Bracket

Gearbox

Side Bracket

Propshaft

Machines fitted with Steel Tanks

have a Return Line Filter mounted at

the bottom of the gearbox bracket

Refitting Gearbox

Before Refitting Gearbox Ensure ALL Worn and

Damaged Components Have Been Replaced

z Clean inside bell housing and check for gearbox oil leaks.

Also check the spigot bearing in the end of the crankshaft is

free from damage and wear, replace as necessary.

z Lower the gearbox into the frame and enter the first motion

shaft into the crankshaft spigot bearing.

z Ensure the gearbox is in gear and the gearbox is in line

vertically and horizontally with the engine. When the splines

of the first motion shaft are against the splines in the clutch

plate turn the gearbox output flange to align the splines. When

the splines are aligned push the gearbox fully into position.

z Turn the gearbox to align the bell housing and engine fixing

holes, refit the eight setscrews around the bell housing and

tighten. Refit the propshaft.

z Loosely refit the anti-vibration crossmember complete with

the right hand gearbox bracket. Fit the left hand gearbox

mount and return line filter bracket. refit the two nuts and

bolts holding the gearbox side brackets together at the top of

the gearbox.

z Take the weight of the gearbox / engine assembly and remove

the piece of wood supporting the front of the engine.

z When all the fixings are in place, fully tighten the side bracket

nuts, the two top nuts and bolts and the four nuts and bolts

holding the anti-vibration crossmember.

z Remove the lifting sling.

z Replace the clutch operating rod. Adjust as necessary.

z Replace the battery and reconnect.

z Replace the floorplate.

z Road test the machine and rectify any problems.

Make Sure the Clutch Pedal Start Inhibitor is Working Correctly

Loading...

Loading...