As close

as possible

Pipe

Diameter

"D"

Rigid Wall Flexible

Suction Hose with

quick connect shown.

Eccentric Reducer

flat side up.

Short length of

straight pipe.

(2 times pipe diameter)

Connection for remote hand primer

or for manual priming.

4 x "D"

minimum

1 x "D" minimum

from bottom

Strainer / Foot Valve

To keep debris from entering

pump suction and to maintain

pump prime after shut-off.

Connection for optional Engine Exhaust

Primer. Locate at least one (1) pipe

diameter from pump case.

Portable Installation is most

common with this style pump.

Typical of permanant

installation using standard

pipe and fittings.

Suction

Gauge

Eccentric Reducer

flat side up.

Support pipe

as required

Standard or long

radius elbow.

Slope upward

to pump.

Straight run, short as possible but

at least 6 times pipe diameter ("D")

after elbow to stabilize flow.

All connections must

be

air tight.

NOTICE:

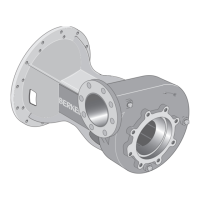

Companion

Flange Kit

Companion

Flange Kit

Companion

Flange Kits

• Recommendations called out in field of drawing apply to

both suction connections shown.

• Use pipe, tubing or reinforced hose to make suction con-

nection. Hose must have sufficient strength to resist col-

lapse under pressure differential that occurs while pump is

running.

• Suction pipe size should be at least one commercial pipe

size larger that opening in pump inlet. Flow velocity should

not exceed 8 ft./sec.

• Suction screen area must be at least four times suction pipe

area.

• Net Positive Suction Head Available (NPSHA) must exceed

Net Positive Suction Head Required (NPSHR) by the pump

or reduced performance and severe pump damage may

result.

• All suction piping must have a continuous rise to the pump

suction inlet. For rigid pipe or tubing, a 1/4 inch per foot

minimum slope is recommended.

Loading...

Loading...