• Use pipe, tubing or reinforced hose to make discharge

connection. Hose must have sufficient strength to contain

the pump discharge pressure.

• Discharge pipe diameter should be at least one nominal

pipe size larger than discharge opening in pump and sized

so that flow velocity is below 8 ft./sec.

• Use only non-slamming check valves to prevent hydraulic

shock (water hammer).

• Use gate, ball or butterfly valve for isolation. Valve should

be full open during operation.

• Maintain proper size throughout discharge system, using as

few elbows and tees as possible to keep friction loss to a

minimum.

• Install pressure gauge after reducer to check operating

pressure.

Page 12 F00636

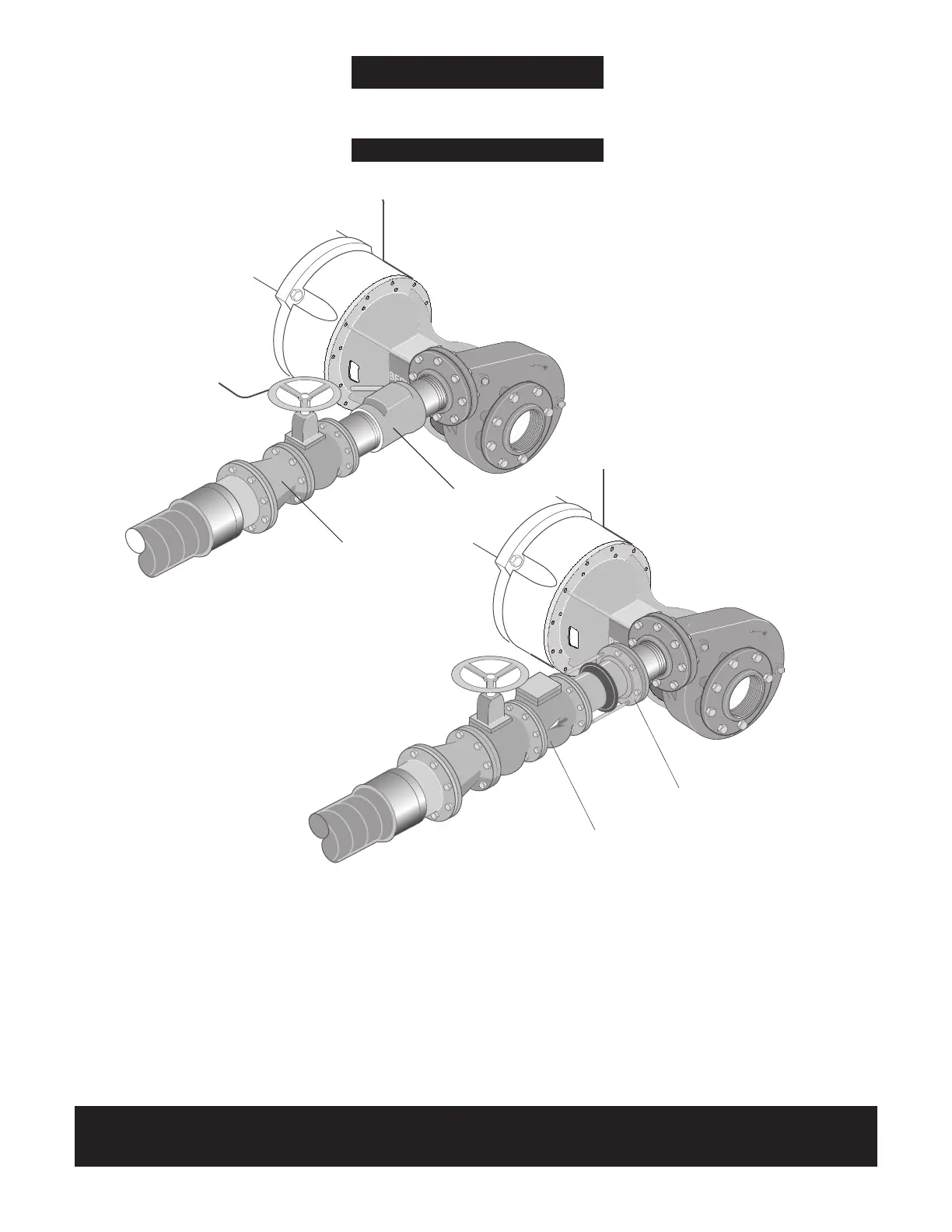

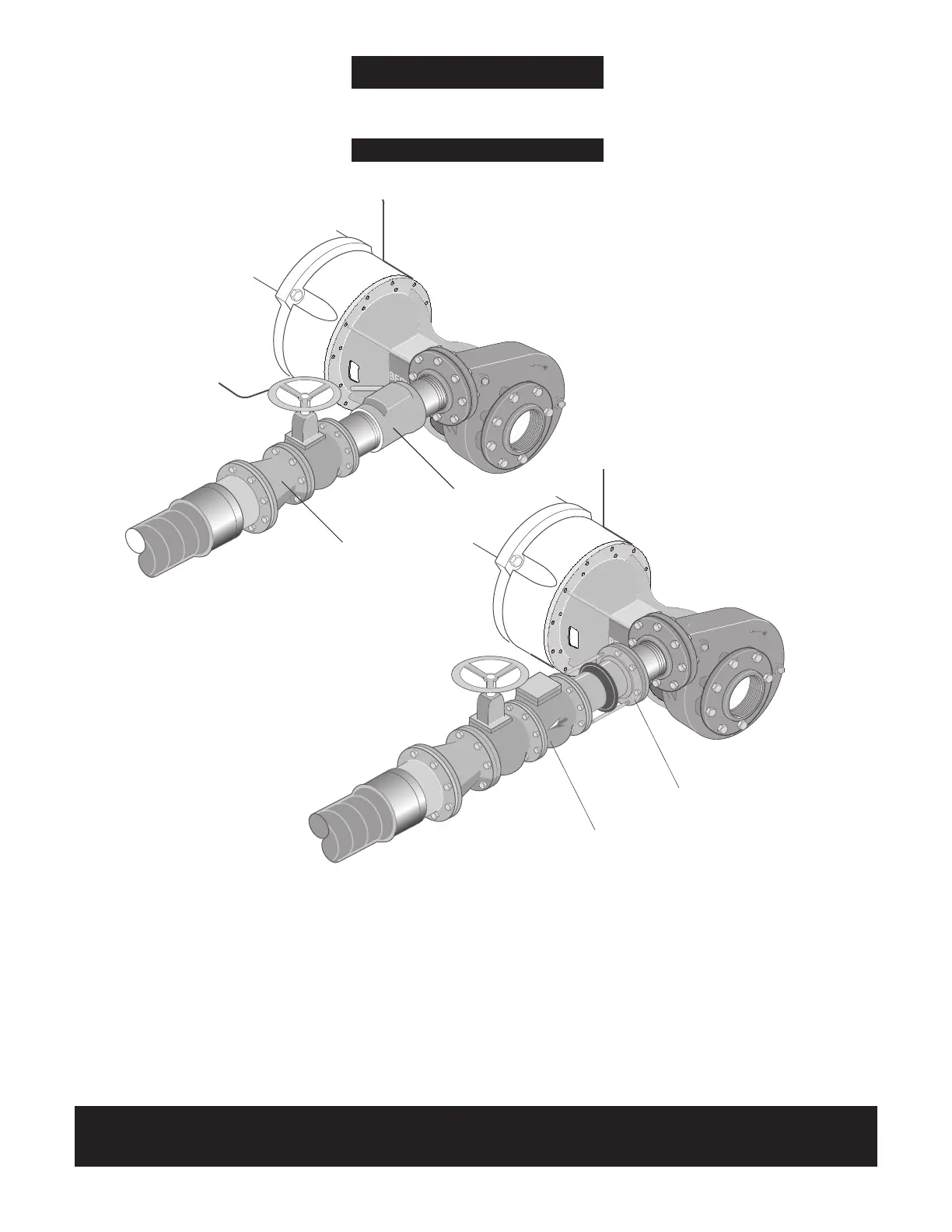

Discharge Connection

Installation

Recommended

air tight.

rods.

to minimize friction losses.

as required.

Loading...

Loading...