Page 20 F00636

• Remove volute to expose impeller.

• Peel off old volute gasket (or O-Ring) and discard.

NOTE: Certain models such as the B4EY, are constructed

with a suction cover which is removed first to access impeller.

GENERAL

• Shaft assembly of S.A.E. mounted pumps should be

periodically (annually minimum) torn down for inspection of

worn parts, cleaning, and re-greasing. Most importantly, to

check shaft sleeve and bearings for pitting. Replace worn

components as necessary. Parts may be ordered sepa-

rately as required, or for some models, shaft kits are

available that are completely assembled and ready for

installation.

PUMP DISASSEMBLY

• Remove packing gland and packing arrangement as

described in Page 17.

• Remove pump volute and impeller as described on Pages

18 and 19.

• Remove outer bearing cap and slide shaft assembly from

bearing bracket.

• Clean and inspect all components.

SHAFT INSTALLATION

• Thoroughly steam clean or solvent wash the bearing cavity

of bracket to remove old grease and dirt. Check surface of

bracket for cracks, extreme corrosion, or other defects.

• Pack bearings with a lithium-based NLGI No. 2 extra

pressure ball bearing grease (see “Lubrication”, Page 16).

Force enough grease into each bearing to fill internal space

between the races.

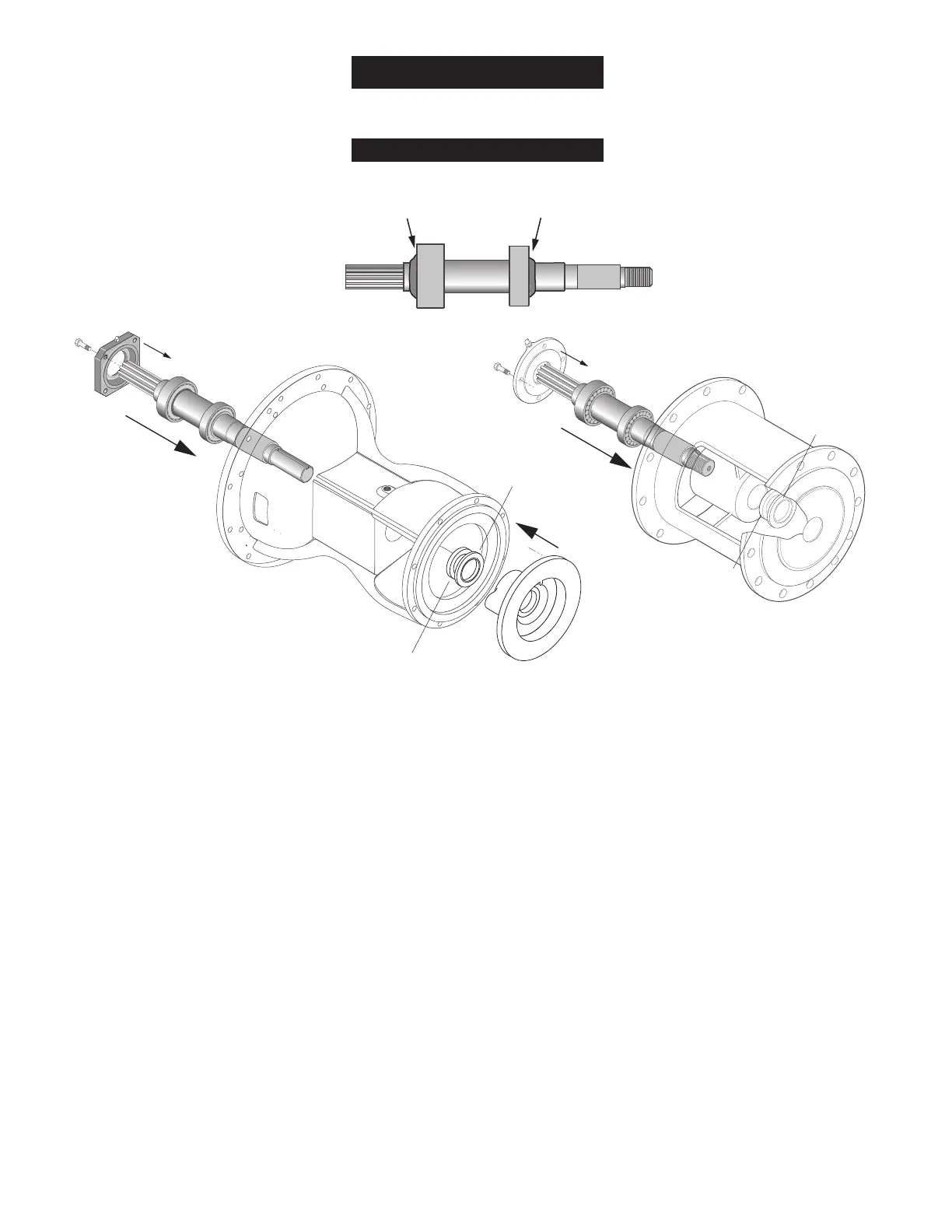

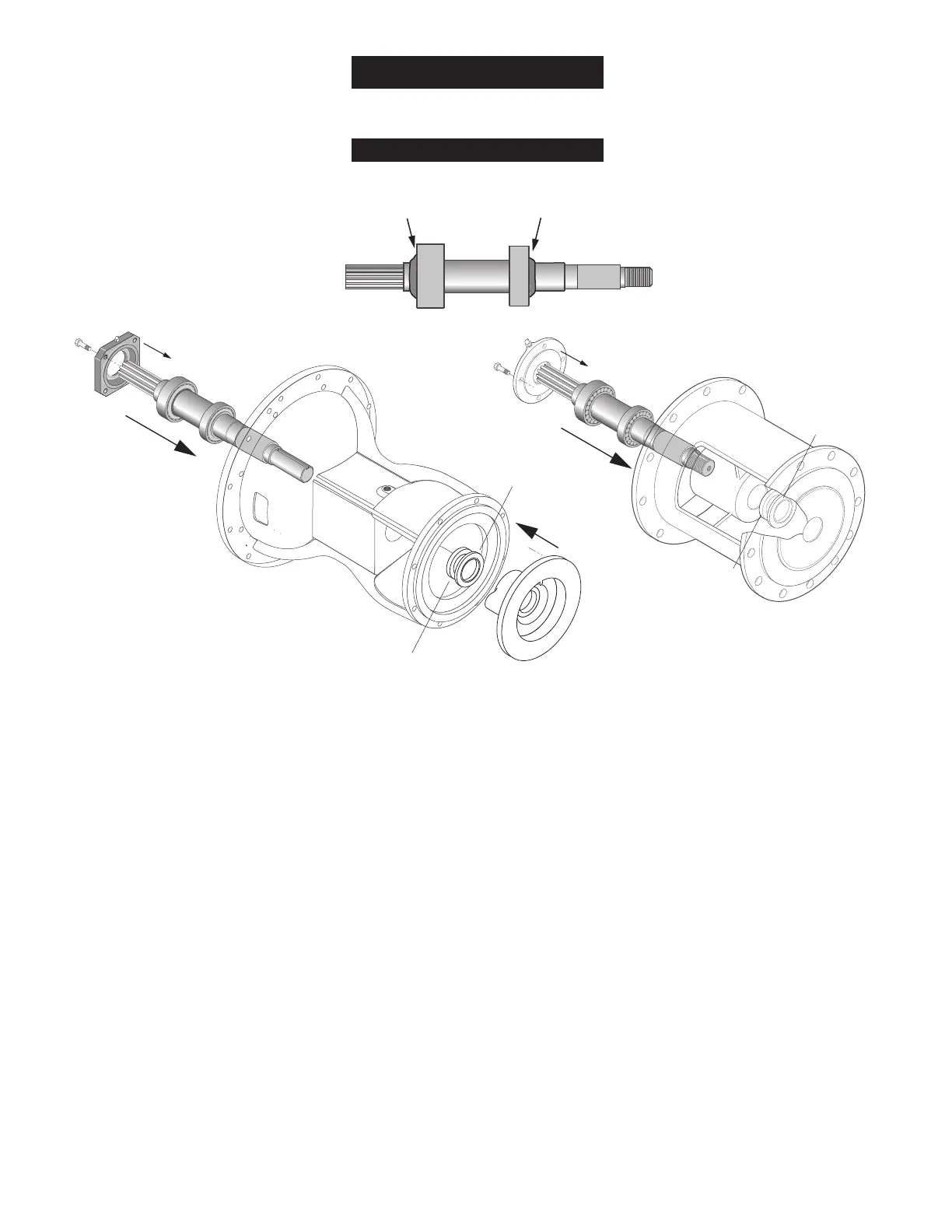

• Coat the bearing bores of bracket with oil. Orient shaft

assembly in the direction shown above. Slide shaft and

bearing assembly into bearing bracket.

Do not force them!

When threaded end of pump shaft comes through inside

opening of bearing cavity, place oil seal, water slinger, and

lantern ring over end of shaft. If packing gland or seal

retainer is not of the split variety, place it over the shaft at

this time as well. Slide shaft on through stuffing box until the

first bearing makes contact with the bracket. Carefully align

bearing with the bearing bore and press or tap bearing

assembly into place. Do not use excessive force.

NOTE: Be sure bearing bores and bracket area are clean and

free of contamination or early bearing failure may occur.

• Reinstall outer bearing cap and oil seal.

• Rotate pump by hand, 10-12 rotations.

• Reassemble pump parts and reinstall unit to piping system.

Refer to

Installation

section in this manual for correct

procedure.

Shaft Maintenance/Replacement

Maintenance

Loading...

Loading...