Page 4 F00636

General Information

Installation

LOCATION

Locate the pump as near the water source as practical. Make

pipe run short, straight and with as few pipe fittings as pos-

sible, to keep total friction loss to a minimum.

Install pump in a clean, dry and drained location if possible

and protect against moisture and adverse weather conditions.

Pump should be located on a level, hard surface to prevent

shifting or tipping. Locate to be readily accessible for in-

spection and maintenance.

Because of the portable nature of this style pump, careful

attention should be taken to assure that Net Positive Suction

Head Available (NPSHA) exceeds Net Positive Suction Head

Required (NPSHR) by the pump or reduced performance and

severe pump damage may result.

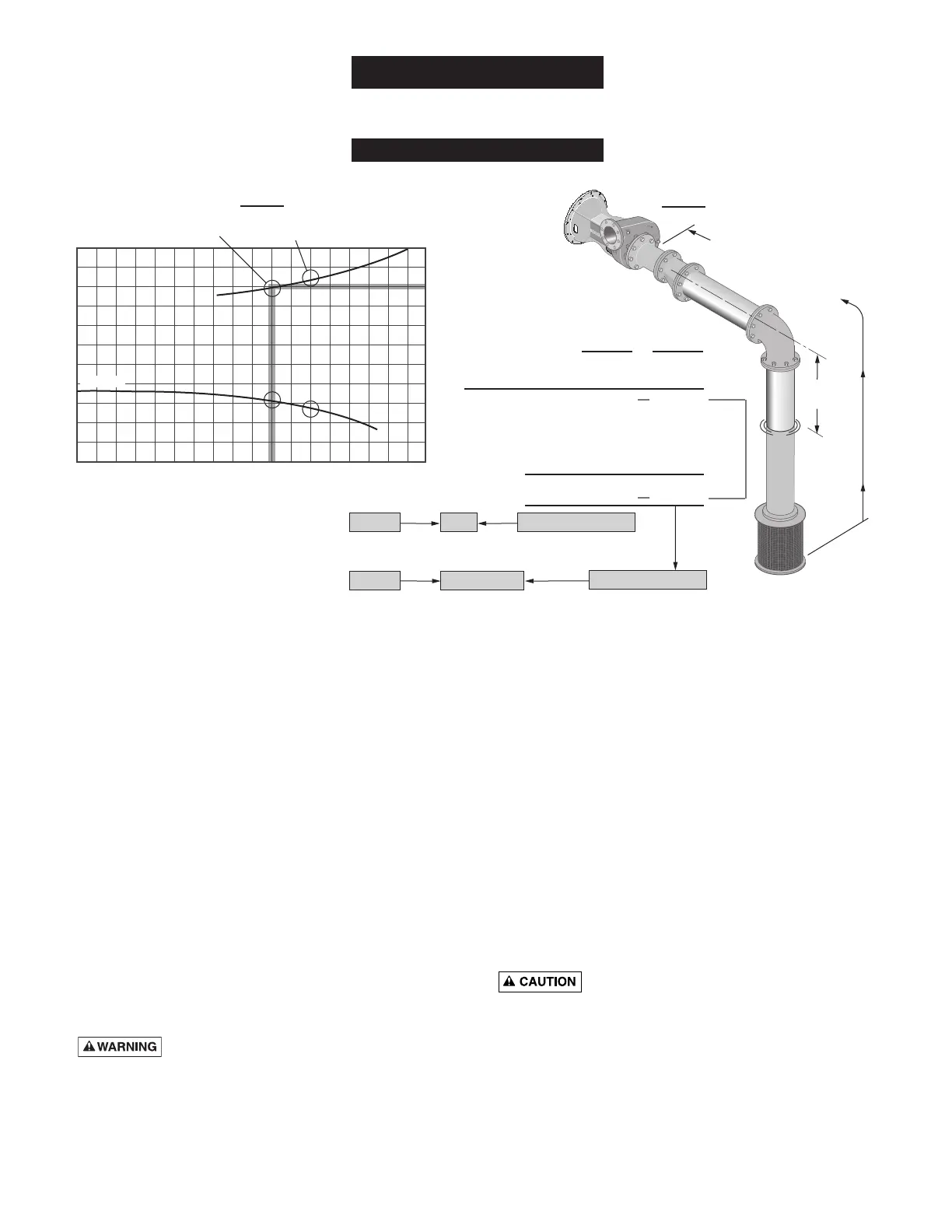

Figure 1, illustrates where these terms (NPSHA / NPSHR)

come from, and how to determine if the pumping conditions at

which you want to operate meet the proper criteria. When in

doubt, consult your nearest Berkeley Professional Dealer.

NOTE: If pump site is 1000 feet above sea level, subtract 1.2

feet from the NPSHA equation and an additional 1.2 feet for

each additional 1000 feet of elevation.

PUMP FOUNDATION

CRUSHING WEIGHT. Models with larger

suction and discharge openings are extremely heavy. Use care

and proper equipment when handling pump for installation.

Be sure to allow for the weight of the water in the pump and

piping.

Portable Installation:

Pump should be placed on an area that will provide a solid

foundation substantial enough to support the weight of pump

and engine and also to provide stability while the pump is

running. Engine vibration will cause shifting on any type of

loose surface and cause piping strains and possible damage.

NOTICE: Settling and/or shifting during operation can cause

piping to place excessive strain on the pump and may

damage pump case.

Permanent Installation:

Pump and Engine should be set on a concrete foundation

which is sufficiently substantial to absorb vibration and which

will provide a permanent and rigid support. Bolt engine directly

to concrete.

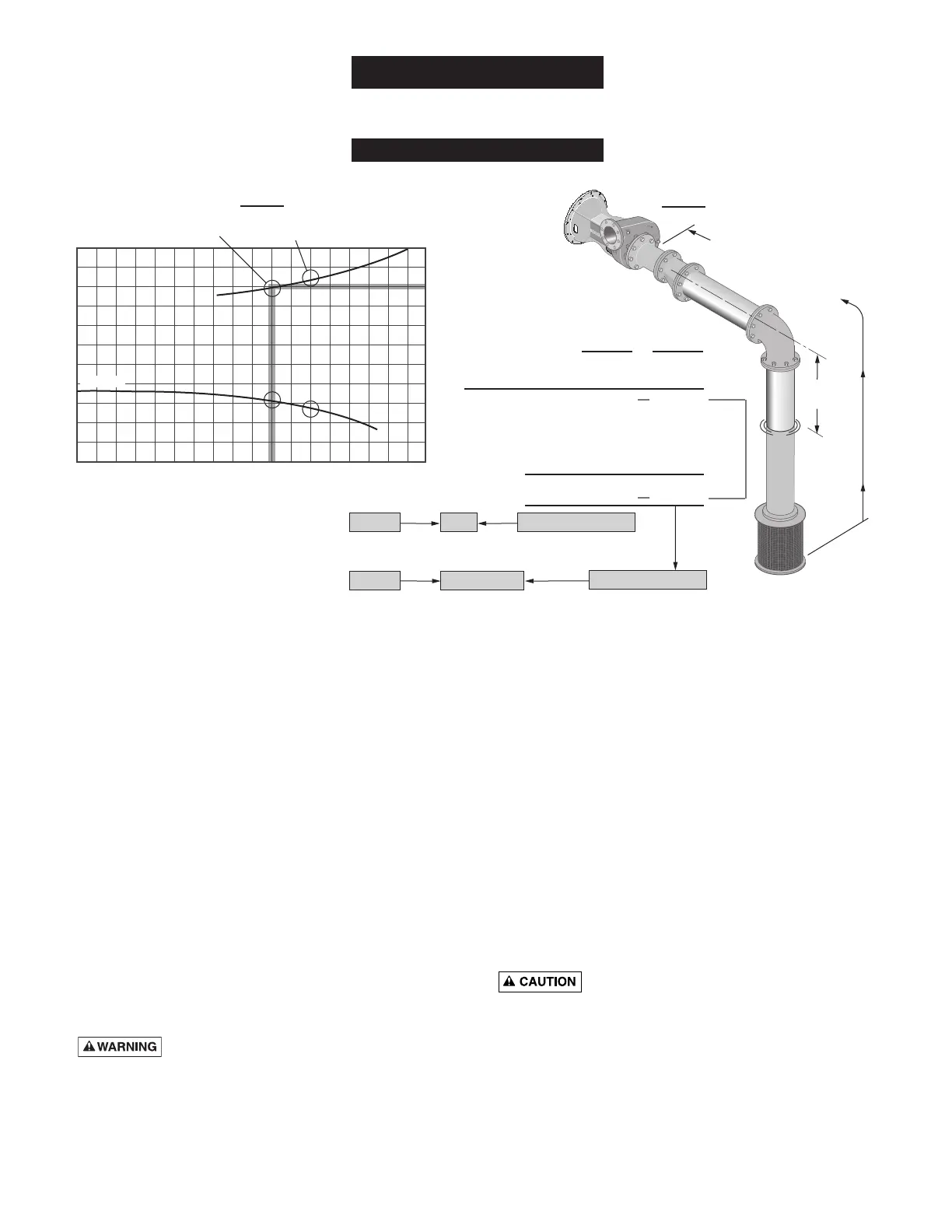

PIPING

System piping should be at least one commercial pipe size

larger than pump connections and flow velocity should not

exceed eight (8) feet per second.

Misalignment of piping with pump case or

excessive pipe strain can cause distortion of pump com-

ponents resulting in rubbing, breakage and reduced pump life.

Insure that piping is supported in a manner that prevents the

exertion of force on pump connections. If ANSI type flange

connections are used, this can be checked by the following

procedure. With the pump shut down, remove pipe flange

bolts. If the mating flanges come apart or shift, misalignment

is present and causing pressure on the connections. Adjust

pipe supports until flanges mate without any force. This

procedure can be done throughout piping system.

at that point on the performance curve.

at that point on the performance curve.

@ 500 Gallons per minute.

@ 600 Gallons per minute.

Loading...

Loading...