22 23

5.6 DeaD BanD setting

MINIGAM+ control board dead band should be adjusted only if the actuator is “hunting”.

In this case, use a small screwdriver to adjust the «Dead Band» potentiometer value until

the actuator stops and stays at the desired position.

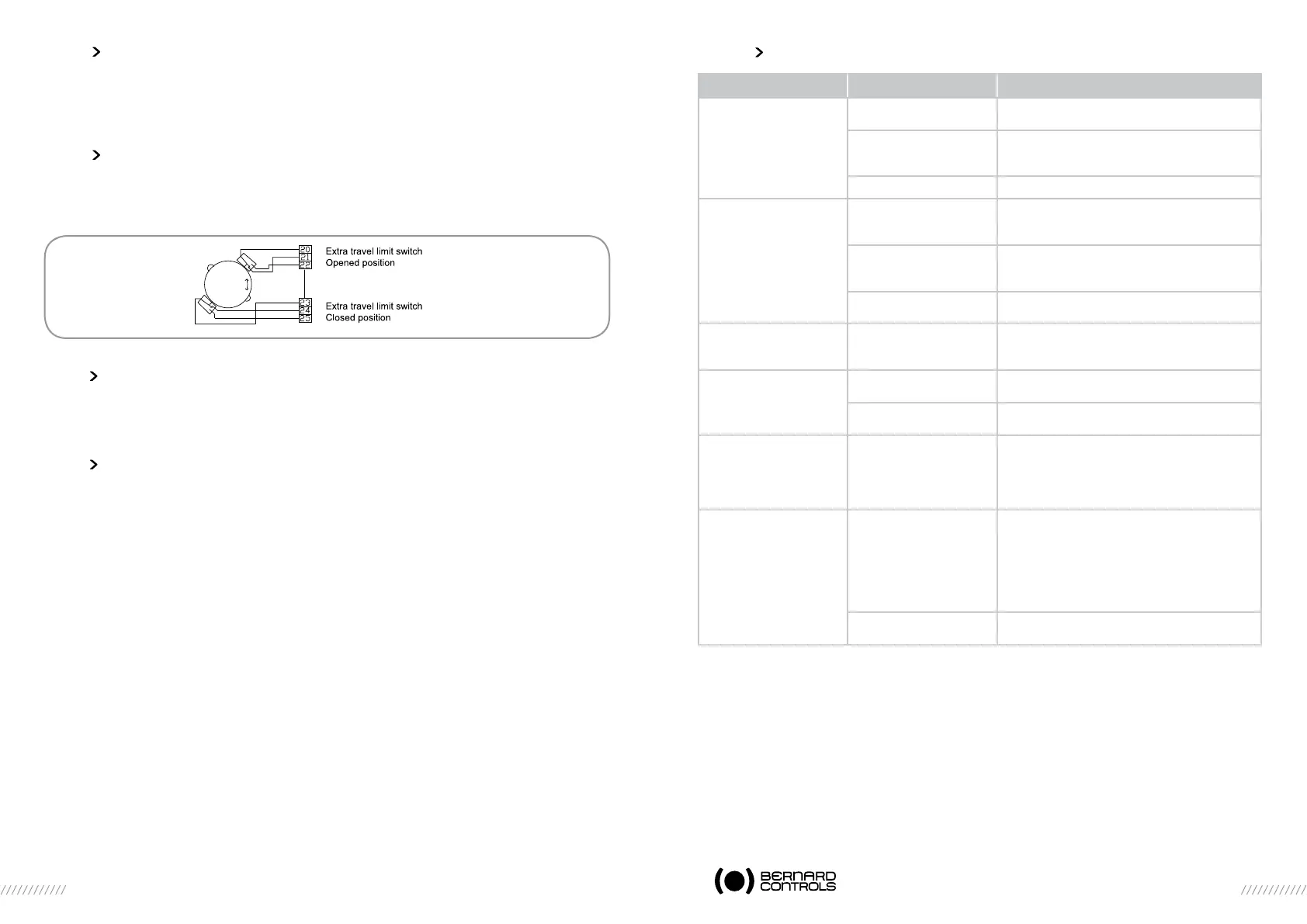

5.7 auXiLiairY controL switches

The OPEN and CLOSED signalling can be managed separately by two separated control switches.

These switches are actuated by brown and grey cams.

They can be connected through terminals 20 to 25as follow :: :

5.8 heating resistor

To avoid any condensation, each EZ actuator is equipped with heating resistor. It’s recommanded to

supply the heater as soon as the actuator is on site.

5.9 caution

Replace covers immediately after start-up and make sure that their seals are clean. Never fail

to replace the protection covers. If water ever enters, dry thoroughly before replacing covers.

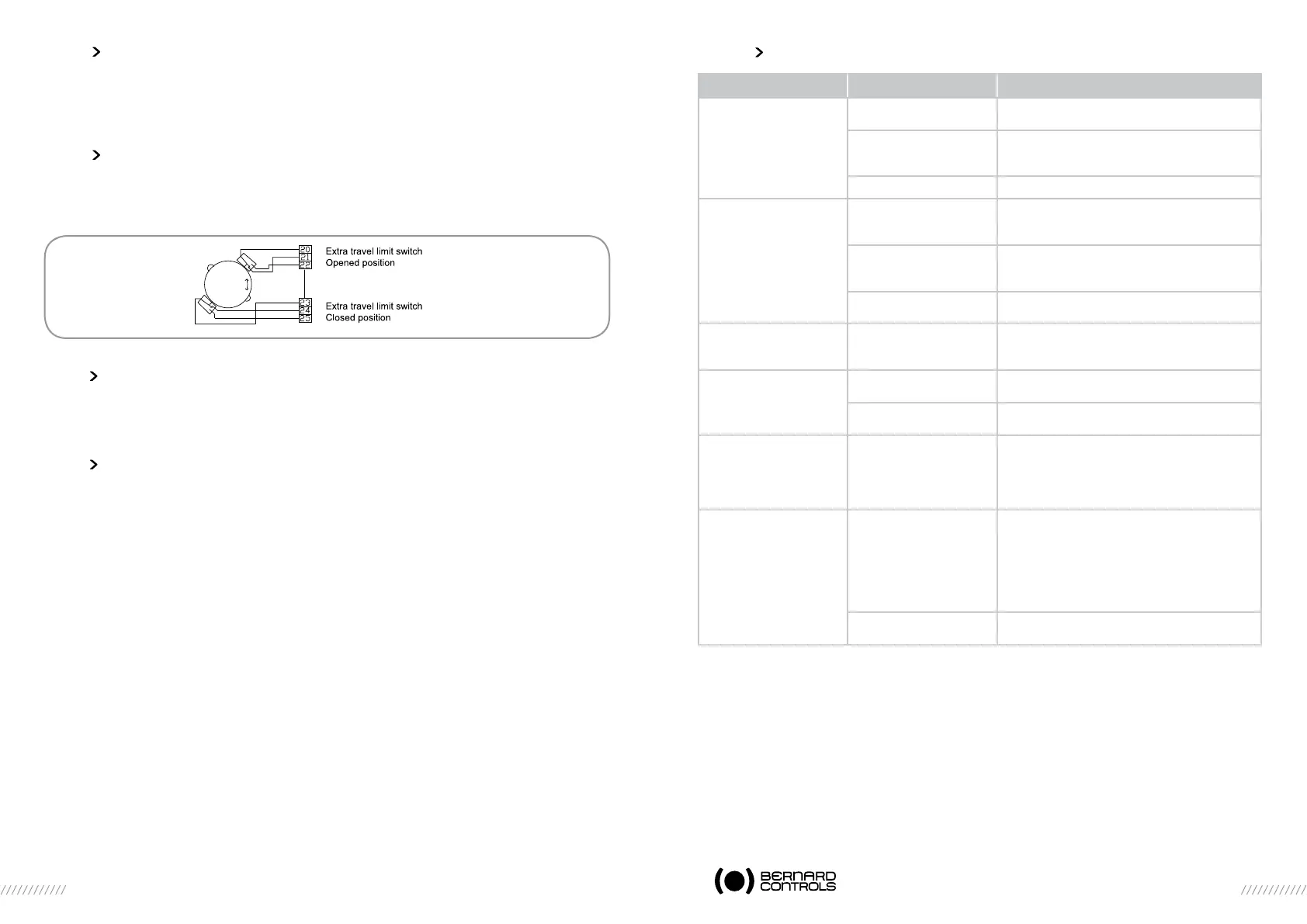

5.10 trouBLeshooting

PROBLEM CAUSE CORRECTIVE ACTION

No operation

No LED on.

Motor thermal protective

device tripped

Check if the motor is hot. The actuator will be

available after the motor has cooled down.

Actuator power supply Check the power supply voltage between termi-

nals L and N. Compare to voltage indicated on the

identification plate.

Blown fuse Check the fuse and replace if required..

The actuator does not

follow the commands.

The yellow LED is on :

Torque limit switch is

tripped

f the actuator has stopped on a mechanical stop,

disengage it with the handwheel and set again

the stroke (stops and end of travel switches).

Incorrect switches

configuration

Check the switches are set according to the

actuator configuration (Minigam board)

Check the input signal switches configuration.

Bad wiring Check input signal connection between the

terminals 70 and 71

The actuator does not

stop on the right position

and is hunting.

Dead band setting is not

correct.

See paragraph 5.6

The remote position

feedback signal is wrong.

Bad wiring Check signal with a voltmeter or a milliammeter

between terminals 71 and 72

Incorrect switches

configuration

Check that switches are set correctly

The torque limiter

indication does not

diisappear once the torque

limiter sensor is no longer

tripped.

Torque limiter data storage The torque limiter data are stored electronically.

To clear a torque limiter memory, a reverse

command must be sent.

The actuator does not

follow the input signal.

Reversed potentiomèter Check potentiometer connections.

Potentiometer is connected on 16-17-18 positions :

- 4mA (or 0mA or 0V) = Closed position and

clockwise closing.

Potentiometer on 18-17-16 positions :

- 4mA (or 0mA or 0V) = Open position and

clockwise closing.

Direction of rotation Check switch 7 setting :

Switch 7 on A : clockwise rotation for closing.

Loading...

Loading...