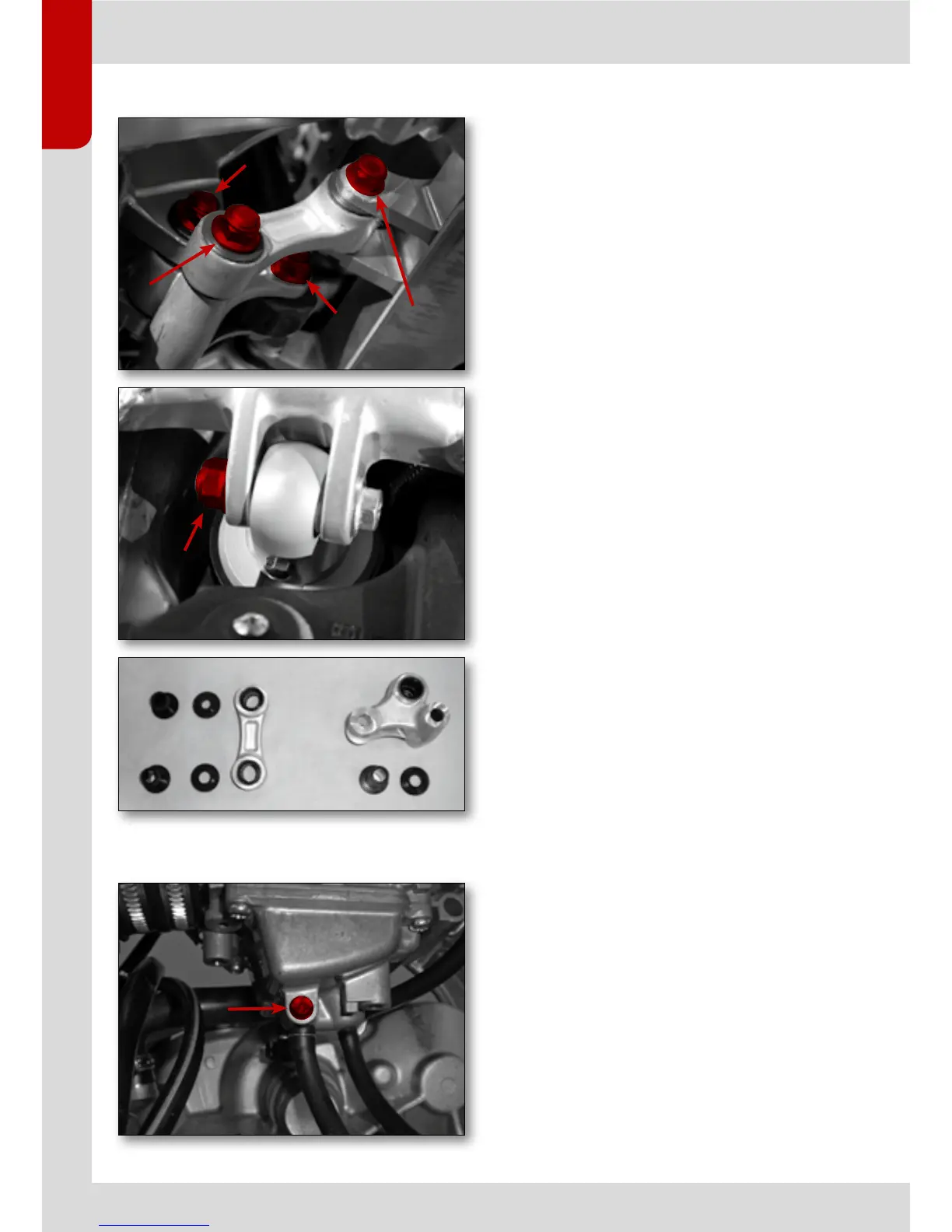

A

C

D

B

E

A

REAR SUSPENSION LINKAGE

To guarantee optimum operation and wor-

king life of the rear suspension progressi-

ve linkage, it is advisable to check that the

nuts and bolts A, B, C, D and E are correctly

tightened after every journey. Proceed as

follows:

Remove the linkage by unscrewing screws -

A, B, C, and D.

Remove the bushings. -

Clean all the parts with a dry cloth. -

Lubricate the bearings and the bushings -

with lithium grease.

Reassemble the unit, starting by securing -

the connecting-rods to the frame, using

the bushings with an inner diameter of 8

mm and the special M screws.

Secure the relay-arm to the swingarm, -

using the bushings with heads which are

2.5 mm thick and the M 10x75 screw, and

to the shock absorber (M10x45 screw).

Then mount the connecting rods on the -

relay arm using the remaining bushings

and the M10x125 screw.

Note

The prescribed tightening torques are 4.5 kgm for

screws A, B, C and E and 3.0 kgm for screw D.

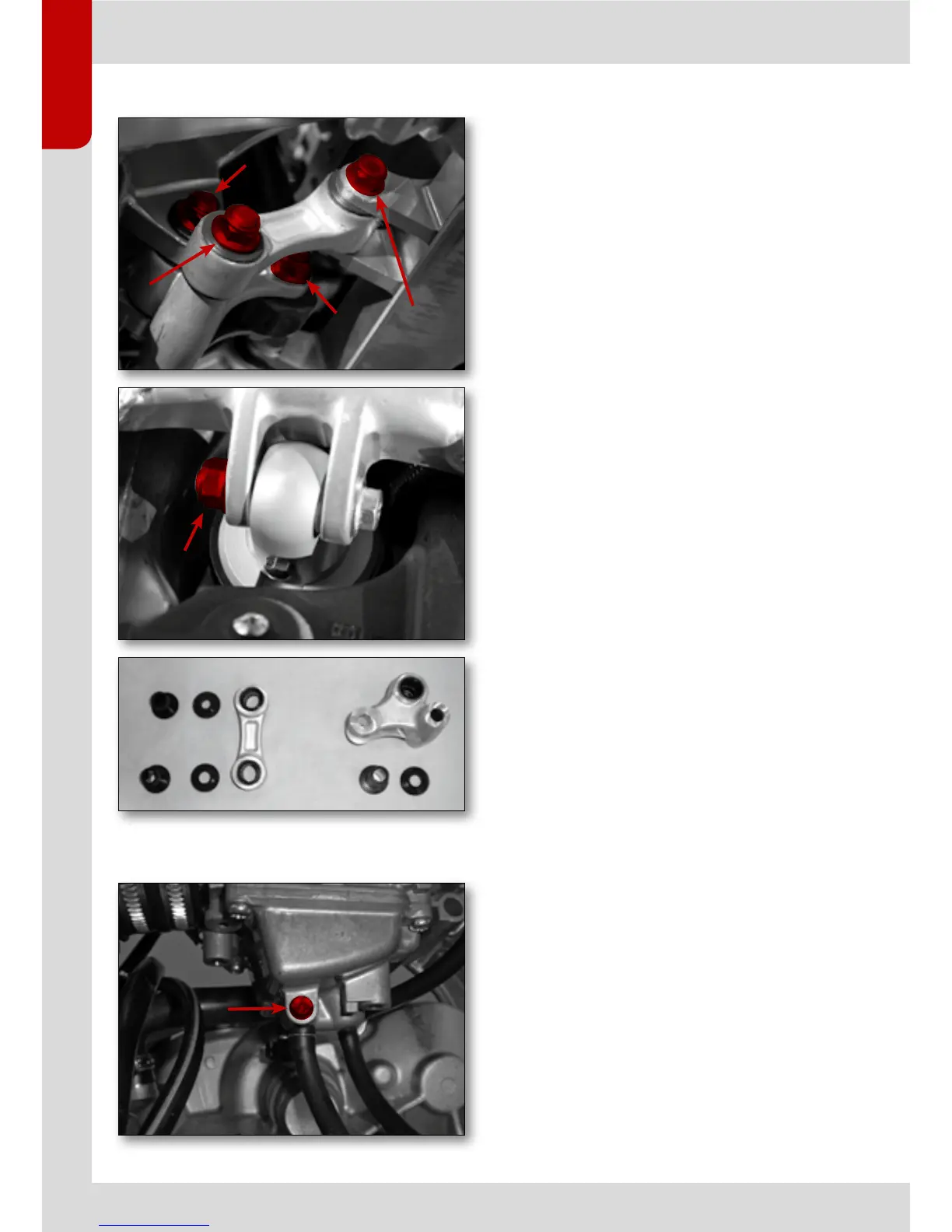

CHECKS AFTER CLEANING

After cleaning the motorcycle, it is good

practice to:

- Clean the air filter (proceed as described

on page 65).

- Grease the drive chain.

- Remove any water inside the carburet-

tor tank by unscrewing the screw positio-

ned on the bottom of the carburettor float

chamber

Note

This operation must be performed with the re-

serve valve closed.

Loading...

Loading...