24

MAN 604A Rev. 5

Operation and Use

Section 3: Operation and Use

3.4 Preparation for Start-up

3.4.1 Pneumatic Connections

Connect the actuator to the pneumatic feed line with ttings and pipes in accordance to

the plant specications. They must be sized correctly in order to guarantee the necessary

airow for the operation of the actuator, with pressure drops not exceeding the maximum

allowable value. The shape of the connecting piping must not cause excessive stress to the

inlets of the actuator. The piping must be suitably fastened so as not to cause excessive

stress or loosening of threaded connections, if the system undergoes strong vibrations.

Every precaution must be taken to ensure that any solid or liquid contaminants, which

may be present in the pneumatic pipe work to the actuator, are removed to avoid possible

damages to the unit or loss of performance.

The inside of the pipes used for the connections must be well cleaned before use: wash

them with suitable substances and blow through them with air or nitrogen. The ends of the

tubes must be well debarred and cleaned.

Once the connections are completed, operate the actuator and check that it functions

correctly, that the operation times meet the plant requirements and that there are no leaks

in the pneumatic connections.

NOTICE

If necessary to mount components not in Bif scope of supply, please check the accessories

mounting hole details in the documents TN 1028 (for metric dimension) or TN 1028U

(for imperial dimension).

June 2020

Installation, Operation and Maintenance Manual

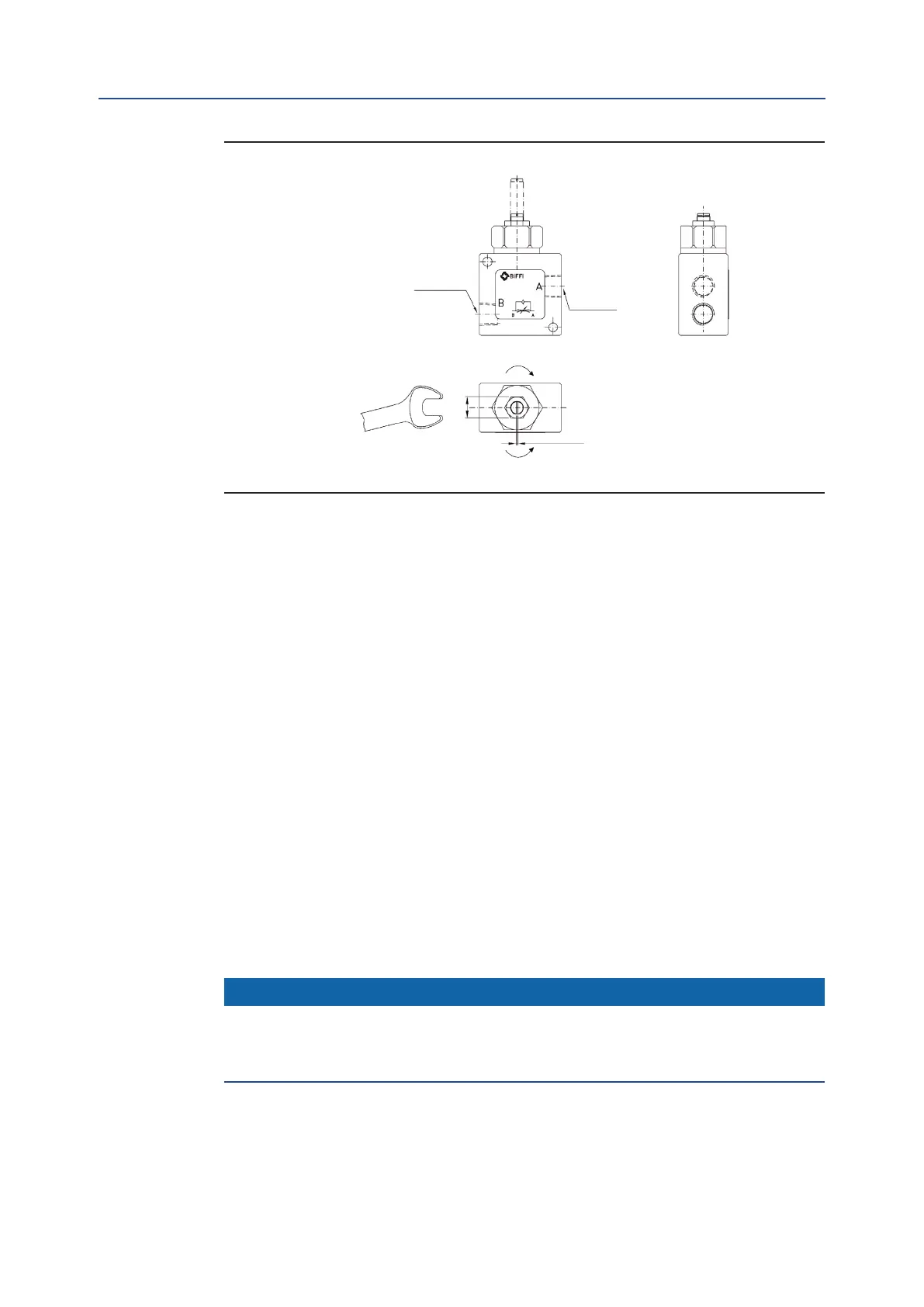

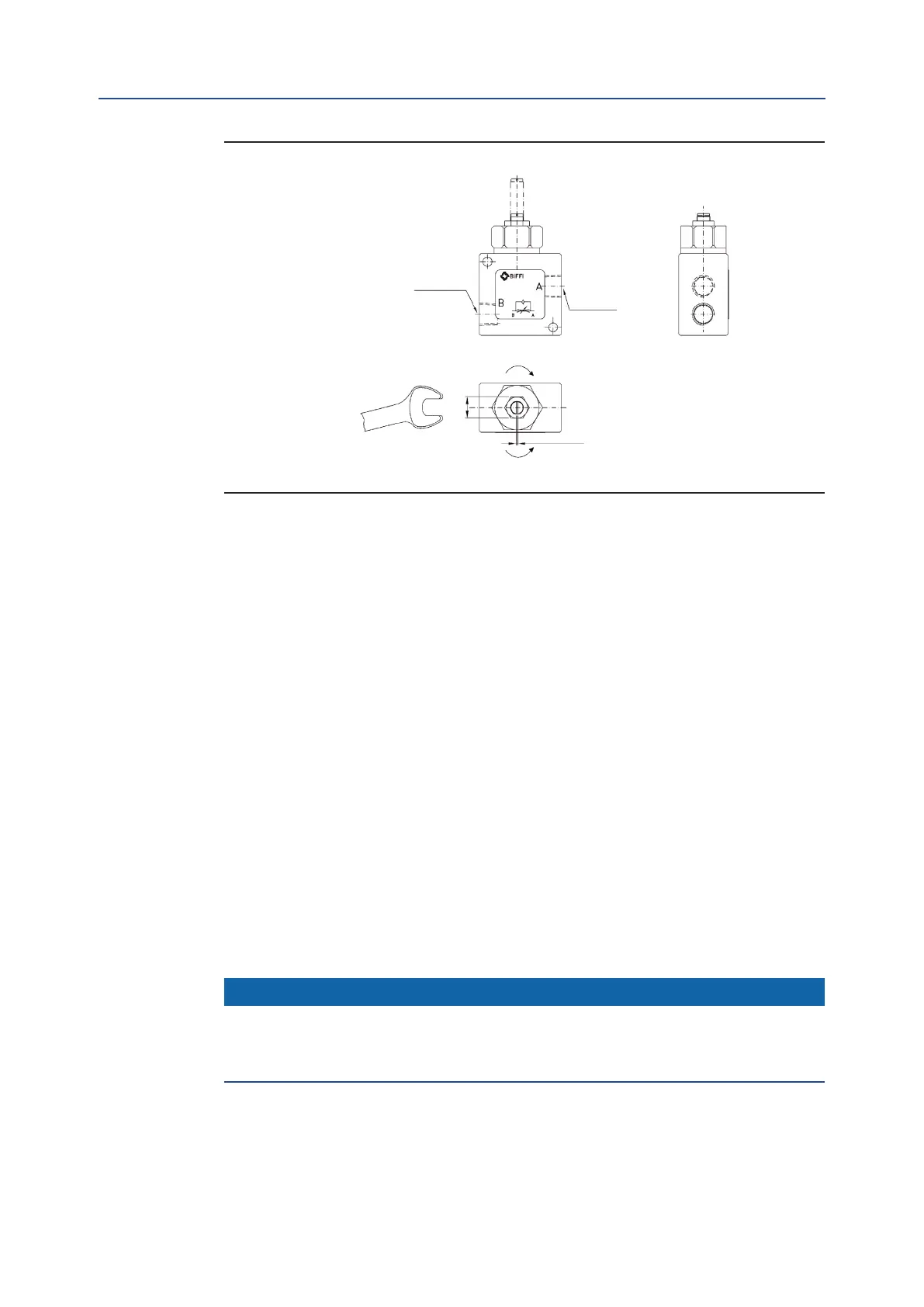

Figure 19 Adjustment of operating time

Pneumatic

connection

Pneumatic

connection

(Close) screw for decrease speed

(open) unscrew for increase speed of operation

Item 278:

see operating diagram

Screwdriver

Wrench

Loading...

Loading...