37

MAN 604A Rev. 5

Layouts and Sectional Drawings

Section 7: Layouts and Sectional Drawings

June 2020

Installation, Operation and Maintenance Manual

Section 7: Layouts and Sectional Drawings

7.1 Parts List for Maintenance and

Replacing Procedure

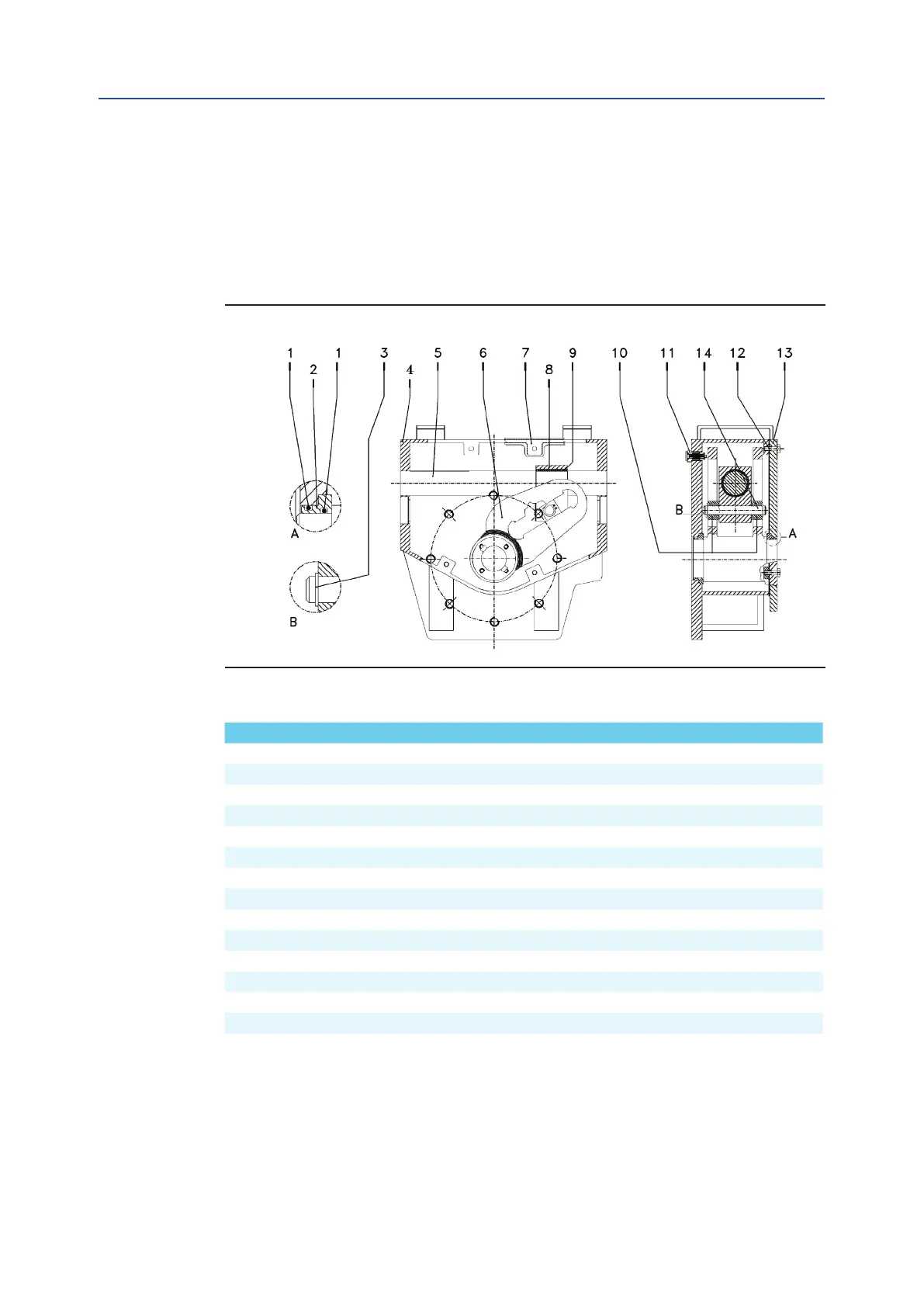

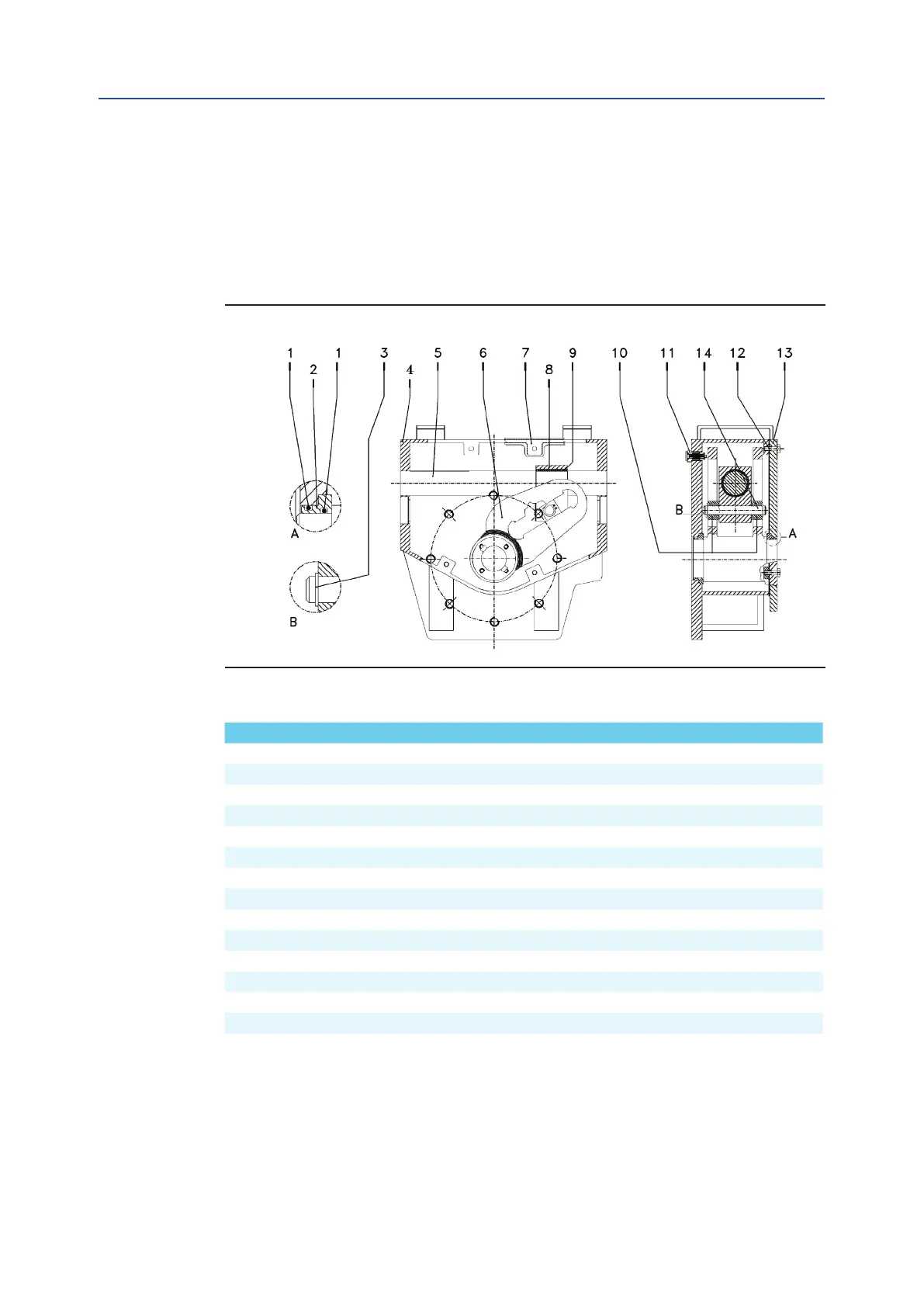

Figure 23 Scotch yoke Mechanism (standard version)

Table 19. Parts list

Item Qty Description Material

1 4 O-ring * NBR rubber

2 2 Yoke bushing Bronze

3 2 Retainer ring Stainless steel

4 1 Housing Carbon steel

5 1 Guide bar Alloy steel

6 1 Yoke Carbon steel

7 1 Cover gasket * SBR+Cellulose+Fillers

8 1 Guide block Carbon steel

9 1 Bushing Steel + bronze + PTFE

10 2 Sliding block Bronze

11 1 Vent valve * Stainless steel

12 12 Screw Carbon steel

13 1 Cover Carbon steel

14 1 Guide block pin Alloy steel

NOTE:

* Recommended spare parts

Cycles performed by actuator in a 25 years expected lifetime - the minimum performed cycles are guarantied

by Bif based on service conditions listed:

— All the valve required torques have to be lower than actuator max operating torque (MOT).

— The ratio between valve required running torque and actuator max operating torque (MOT)

has to be >1.5.

— The actuator mechanism has to be lubricated in accordance witn indication given on this IOM.

Loading...

Loading...