2

MAN 604A Rev. 5

General Warnings

June 2020

Installation, Operation and Maintenance Manual

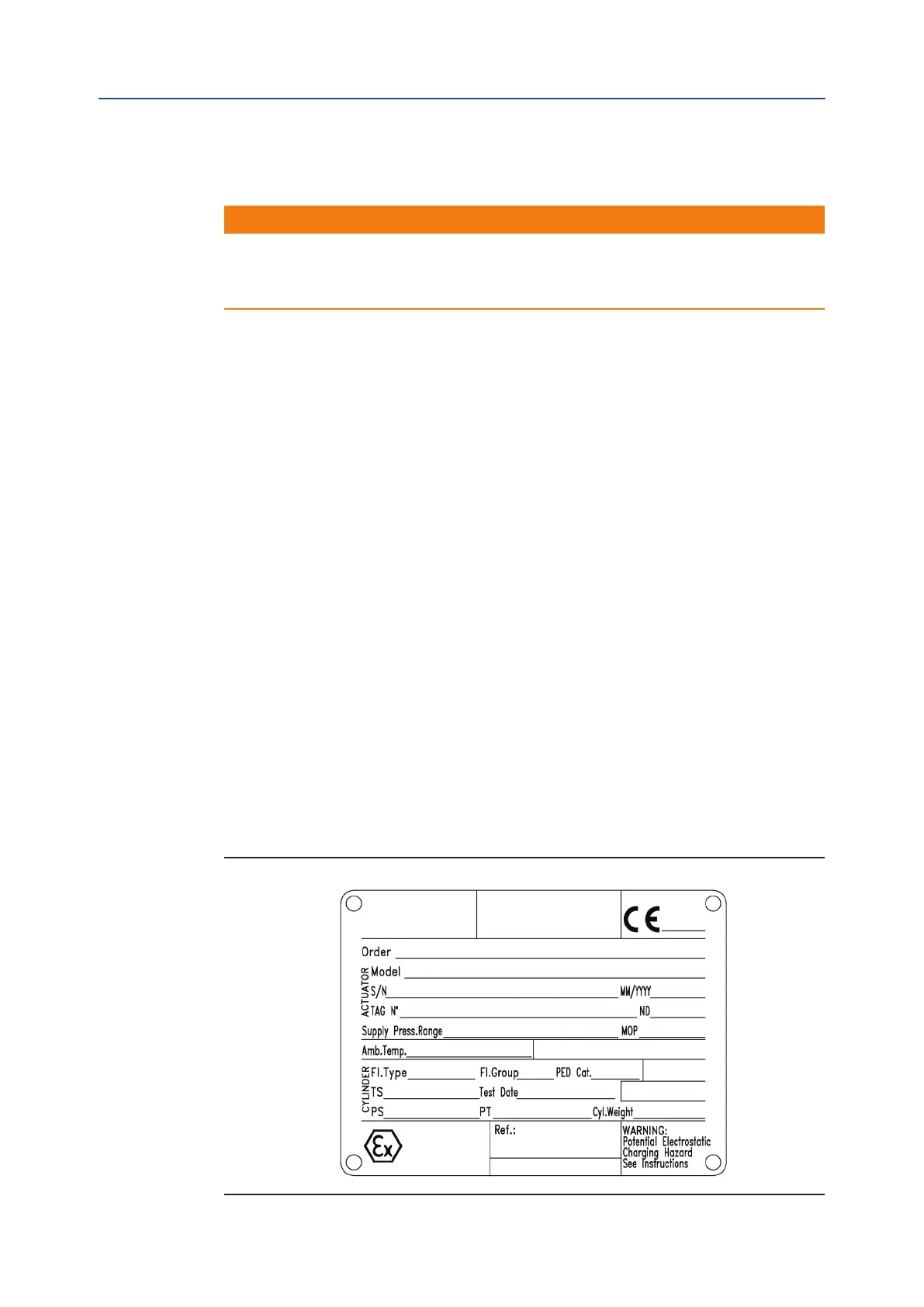

1.2 Identication Plate

!

WARNING

It is forbidden to modify the information and the marks without previous written

authorization by Bif Italia s.r.l. The plate fastened on the actuator contains the following

information (Figure1).

1.3 Description of the Actuator

ALGAS low pressure pneumatic spring-return, are suitable for the operation of

quarter-turn valves (ball valves, buttery valves, plug valves) in both ON-OFF and

modulating heavy-duty service.

The actuator is made up of a weatherproof scotch yoke mechanism transforming the linear

movement of the pneumatic cylinder (or mechanical manual override, if foreseen) and of

the spring into the rotary movement, which is necessary for operation.

The spring-return pack incorporates up to four springs, fully encapsulated in a factory

welded cartridge: this ensures safety to personnel and simplies assembly. The spring

action can be easily changed in the eld from to close in to open or from to open in to close

(modular design).

The angular stroke of the yoke is adjustable between 82° and 98° by means of the external

mechanical stops screwed into the end ange of the pneumatic cylinder and into the end

ange of the spring-return pack. The cover of the scotch yoke mechanism is arranged for

the assembly of the required accessories (position-transmitter, signaling-limit switches,

positioner, etc.) by means of proper matching units. The above mentioned accessories are

operated by the actuator drive sleeve.

The housing of the scotch yoke mechanism has a ange with threaded holes to x the

actuator to the valve either directly or, if required, with the interposition of an adaptor

ange or a mounting bracket.

The actuator yoke has a hole with keyways suitable for the assembly of an insert bush or a

stem extension. Their internal hole is machined (by Bif or at Customer's care), according

to the shape and dimensions of the valve stem.

Bif can supply different types of control system following Customer's requirements.

Section 1: General Warnings

Figure 1 Data Plate

Loading...

Loading...