G G

www.forsmw.com

11

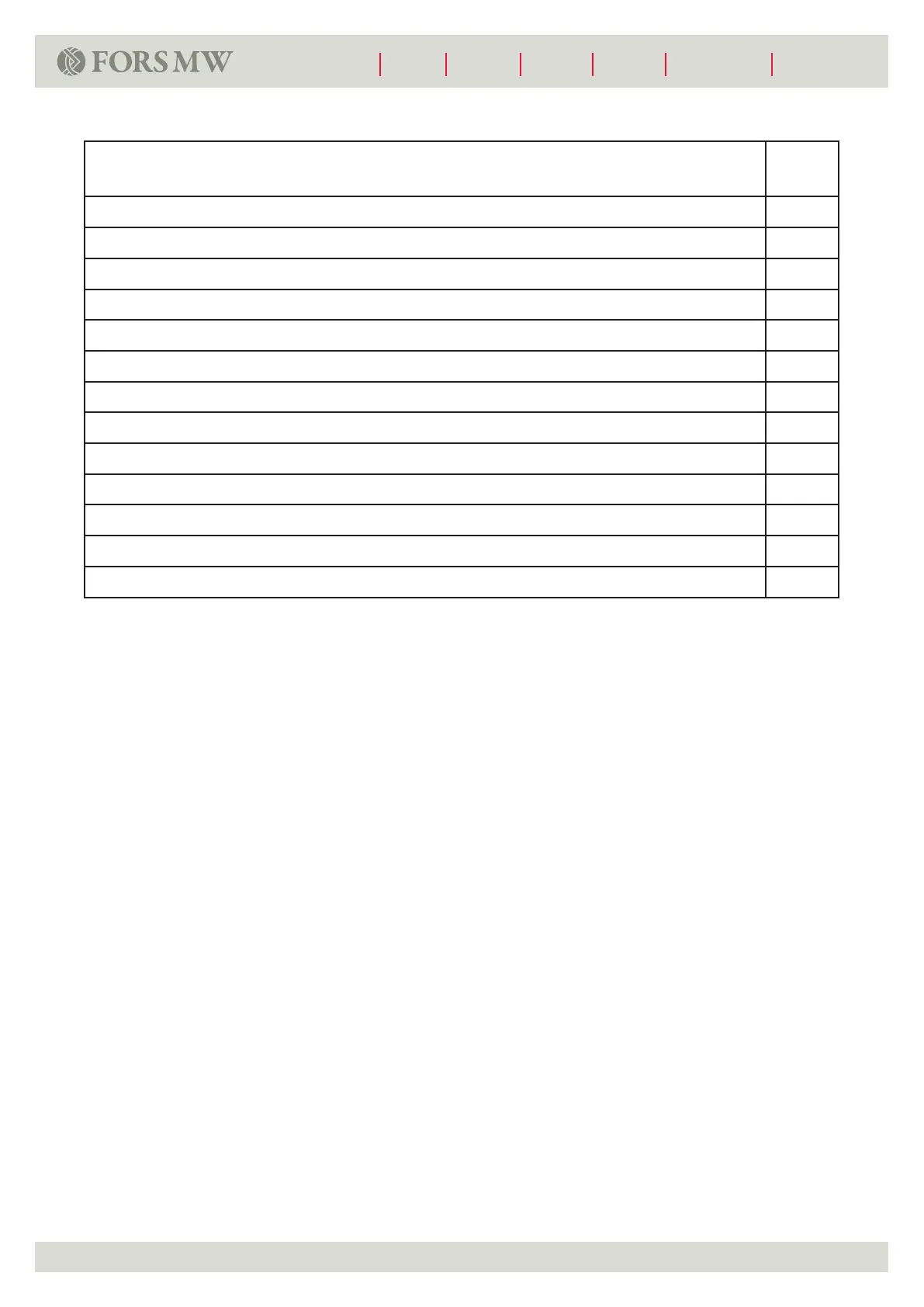

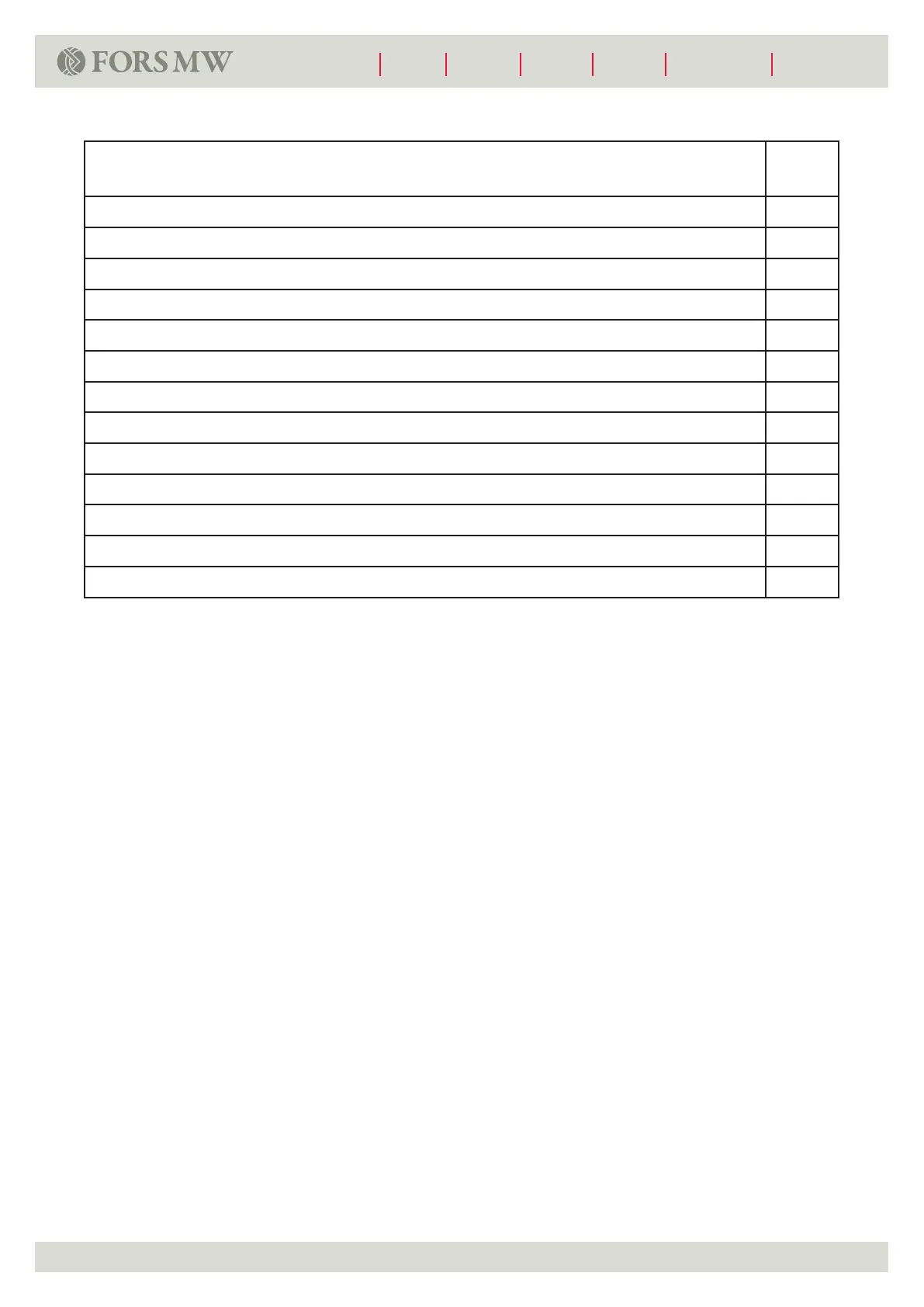

Pre-operation checkpoint

OK/

NOK

Check that personal protection equipment is used and isin good condition.

Check and lubricate the machine per the schedule ( see Maintenance Section)

Check that all bolts, nuts and hoses are connected tightly

Check the towing eyelet for defects

Check that the trailer is s securely and appropriately xed to the towing vehicle

Checkconditionofallhydrauliccomponents. Replace if needed

Check that all hydraulic functions are working

Control the lights

Check that brakes are functioning

Verify that the hook is the right height to suit the container

Check if there is enough working space and turning area

Check the condition of the tires and air pressure.

Check that the wheel nuts are tightened.

CONNECTING MACHINE

Note:

When connecting and disconnecting the BIGAB, bear in mind the risk of clamping injuries, the

risk of slipping, the tipping risk and the risk of hydraulic high-pressure jets and hot oil. Ensure that

neither the hydraulic pump nor the power take-o is connected.

• Check that the towing eyelets’ lock is undamaged and properly tightened.

• Connect the trailer‘s towing eyelet to the towing vehicle’s tow hook. Ensure that the towing

device is properly locked.

• Connect the frame lock.

• Before driving, parking leg must be lifted up and xed with the pin.

Note:Parking brake is only for parking. Not for use during tipping, hooking or loading.

Brakes

• Connect the hoses to the tractor’s brake outlet.

Travel lights

• Connect the light connector to the tractor’s trailer outlet (12V or 24V).

Hydraulic system connections

• Always check that the quick couplings are clean and that they lock properly.

Loading...

Loading...