12’–24’ BASIC 6

®

33

WWW.BIGASSFANS.COM ©2012 DELTA T CORP. ALL RIGHTS RESERVED

12’–24’ BASIC 6

®

Daisy chaining

WARNING: Wait three minutes after disconnecting before servicing!

The following illustrations and parameter changes enable daisy chaining of the Basic 6

®

fan speed controller. The rst fan provides a

start/stop contact and 0–10 VDC analog speed reference for the downstream fan controller. The downstream fan controller provides

a new start/stop contact and 0–10 VDC analog speed reference for the following downstream fan controller. This preferred method of

linking the fan controllers together ensures minimal signal loss of command signals in larger multi-fan systems.

Assertion Level Switch (ALSW)

The fan controller ships with the onboard digital I/O congured for Sourcing (PNP) operation. Terminal 4 provides +15 VDC to be

used as a supply voltage for user-supplied switches and accessories. For this 3-wire daisy chaining application, the downstream fan

controllers must be switched to Sinking (NPN) operation. Terminal 4 will then provide a DC common connection and allow the analog

signal and start stop signal to share that common. The Assertion Level Switch above terminal 4 must be switched from (+) to ( - )

on all downstream fan controllers for proper daisy chaining operation prior to powerup, parameter changes and operation.

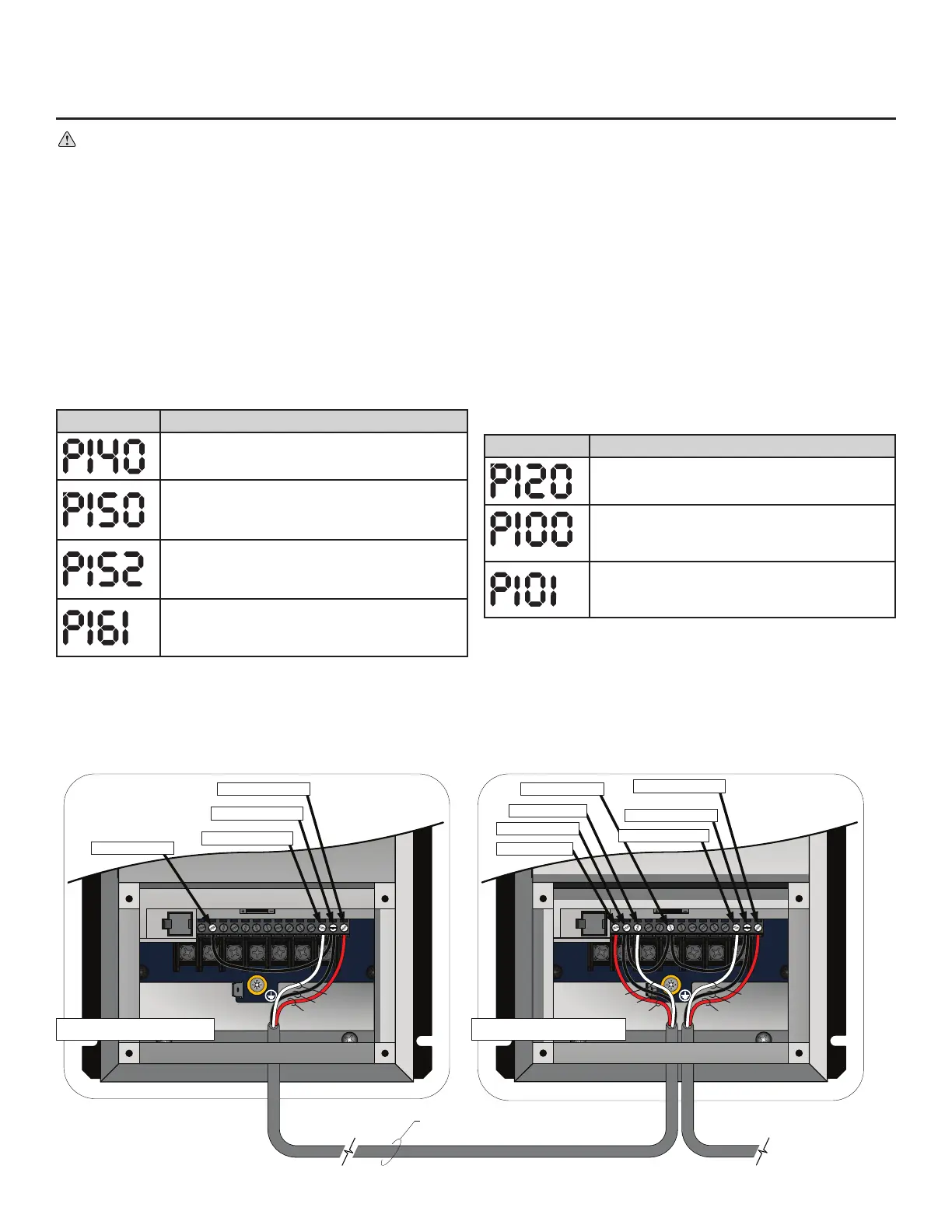

Parameter changes (for rst controller)

Parameter Description

Relay Output Function

Change from “0” for None to “1” for Run.

TB-30 Output

Change from “0” for None to “1” for 0–10 VDC

output (scaled to drive output frequency).

TB-30 Scaling Frequency

Change to equal the frequency setting of P103

Maximum Frequency.

Speed at Max Signal

Change to equal the frequency setting of P103

Maximum Frequency.

Note: Depending on the AWG and distance of the low voltage wiring, the downstream fans may run slightly slower than the leading fan.

If this occurs, P161 Speed at Max Signal can be used to introduce a minor command reference overshoot to compensate for the analog

voltage drop. At each downstream fan (beginning with the rst downstream fan), adjust the value of P161 up 0.1 to 0.2 Hz increments

until the fan’s output frequency matches that of the lead fan.

Electrical Installation (cont.)

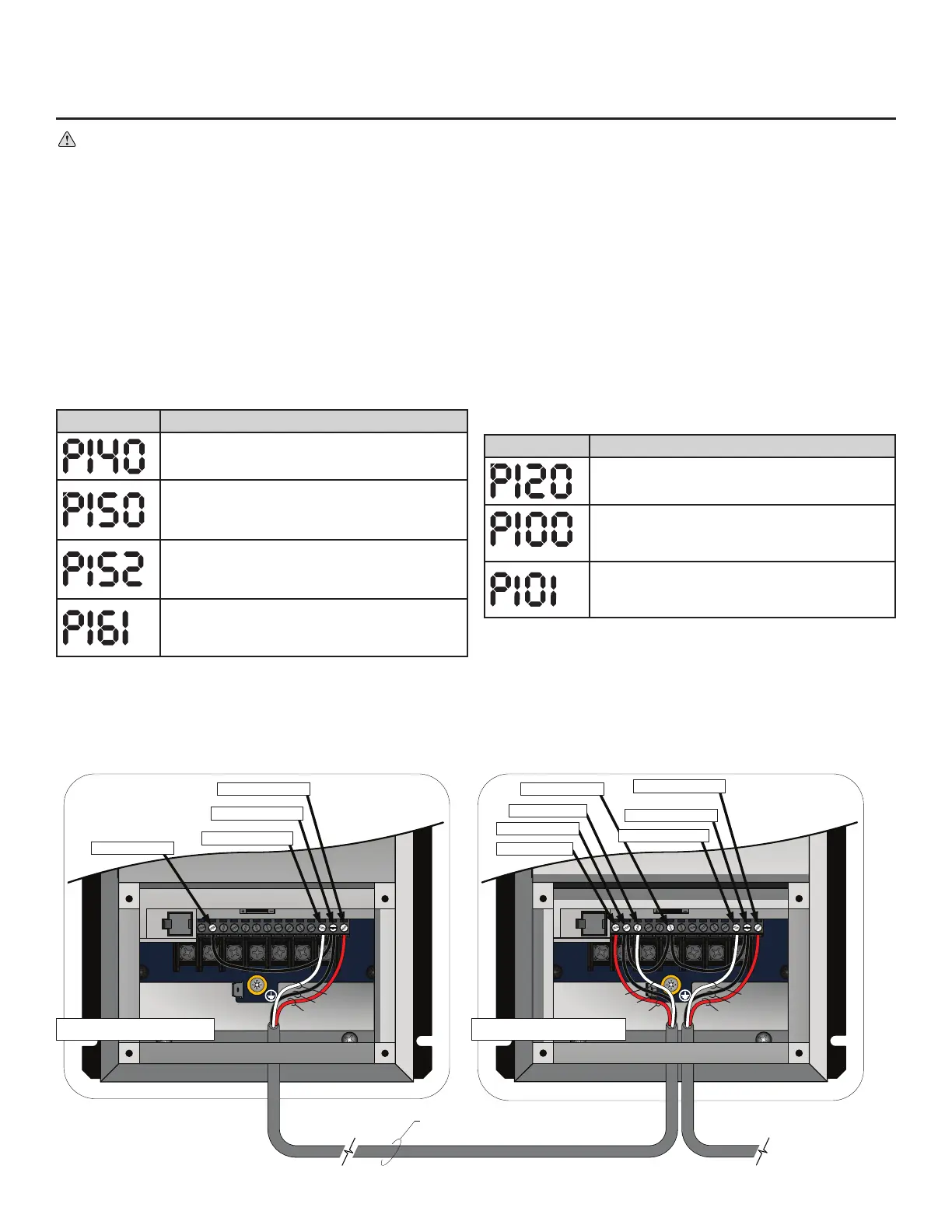

Parameter changes (for downstream controllers)

Parameter Description

Assertion Level

Change from “2” for High to “1” for Low.

Start Control Source

Change from “0” for keypad operation to “1” for

Terminal Strip.

Standard Reference Source

Change from “0” for keypad operation to “1” for

0–10 VDC analog input operation.

U/T1 V/T2 W/T3

PE

L1 L2 L3

1 2 5 6 13A 13B 13C 14 30 16 1725 4 11

1 2 5 6 13A 13B 13C 14 30 16 1725 4 11

U/T1 V/T2 W/T3

PE

L1 L2 L3

1 2 5 6 13A 13B 13C 14 30 16 1725 4 11

1 2 5 6 13A 13B 13C 14 30 16 1725 4 11

#17 = N.O. Relay Output

#17 = N.O. Relay Output

#16 = N.O. Relay Output

#16 = N.O. Relay Output

#2 = Analog Common

3 conductor shielded cable minimum 20 AWG Stranded

(provided by installer) Recommended Maximum distance = 200 ft

#30 = 0–10 VDC Output

#30 = 0–10 VDC Output

#4 = Digital Common*

0–10 VDC and Start/Stop out

to next downstream controller

#2 = Analog Common

Terminals 2 and 16 shall all be tied together

on the rst fan controller.

#1 = Run/Stop Input

#5 = 0–10VDC Input

Terminals 2, 4 and 16 shall all be tied

together on all downstream fan controllers.

RED REDRED

BLK BLKBLK

WHT WHTWHT

Loading...

Loading...