10

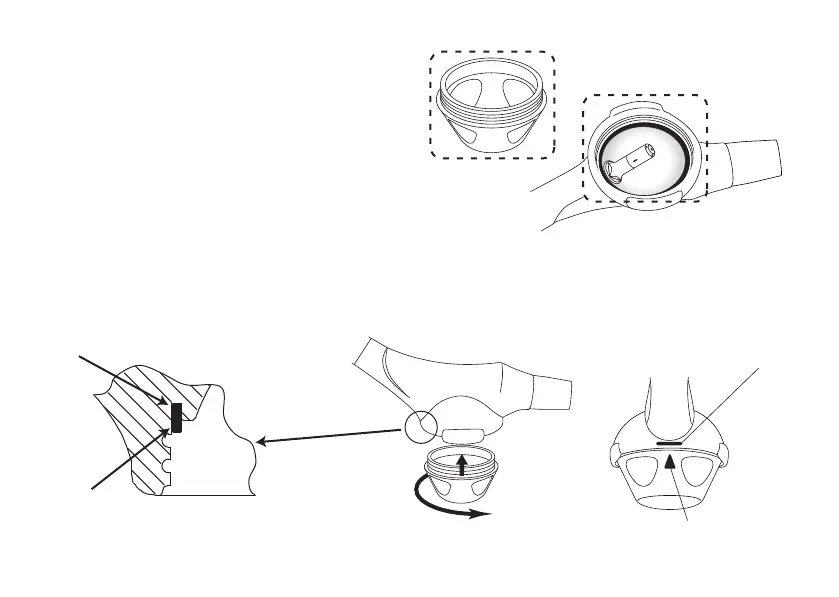

7.3 Attaching head

1) Polisher must be disconnected from a turbine

hose of dental unit when attaching and

detaching the head. If it is connected,

disconnect from the turbine hose fi rst.

2) Confi rm the o-ring of the head is not

damaged.

3) If water, oil, or powder adheres to head or

inside the chamber unit’s coupling, wipe off

with a cotton swab or dry cloth.

4) Align the head to the thread of the chamber

unit’s coupling, turn the head in the direction

of the arrow in the illustration until it stops.

Confi rm secure attachment.

Remove water,

oil, and powder.

Confirm the o-ring of the head

is not damaged.

10

7.3 Attaching head

1) Polisher must be disconnected from a turbine

hose of dental unit when attaching and

detaching the head. If it is connected,

disconnect from the turbine hose fi rst.

2) Confi rm the o-ring of the head is not

damaged.

3) If water, oil, or powder adheres to head or

inside the chamber unit’s coupling, wipe off

with a cotton swab or dry cloth.

4) Align the head to the thread of the chamber

unit’s coupling, turn the head in the direction

of the arrow in the illustration until it stops.

Confi rm secure attachment.

Remove water,

oil, and powder.

Confirm the o-ring of the head

is not damaged.

11

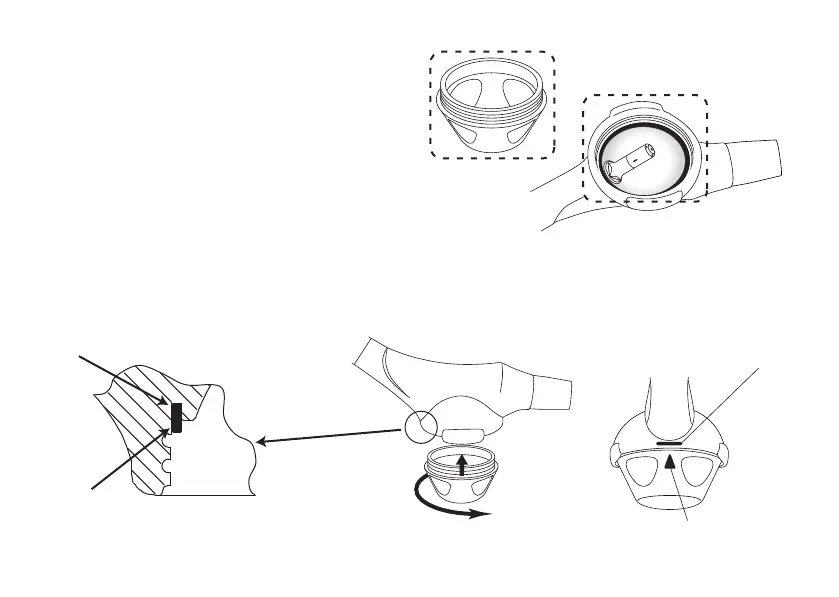

7.4 Attaching powder cap

* Water due to sterilization must be expelled

by an idle run beforehand. Do not fi ll the

powder yet.

1) The powder cap must be attached or detached when

polisher is not connected to a turbine hose. If

connected, detach from the turbine hose.

2) If water, oil, or powder adheres to inside chamber unit,

powder cap, or powder seal, wipe off with a dry cloth.

3) Confi rm the powder seal (blue) is fully engaged in the

groove of chamber unit shown in the illustration.

4) Turn the powder cap in the direction of the arrow in

the illustration until it stops. Confi rm the powder cap is

fi rmly attached and the triangle symbol on the powder

cap lies within the range of the mounting position mark.

In case the triangle symbol lies outside of the mounting

position mark, replace your powder seal with new one

according to “10.4 Replacement of powder seal”.

Remove water, oil,

and powder.

Enlarged sectional view

Groove

Powder seal

Mounting position mark

Triangle symbol

11

7.4 Attaching powder cap

* Water due to sterilization must be expelled

by an idle run beforehand. Do not fi ll the

powder yet.

1) The powder cap must be attached or detached when

polisher is not connected to a turbine hose. If

connected, detach from the turbine hose.

2) If water, oil, or powder adheres to inside chamber unit,

powder cap, or powder seal, wipe off with a dry cloth.

3) Confi rm the powder seal (blue) is fully engaged in the

groove of chamber unit shown in the illustration.

4) Turn the powder cap in the direction of the arrow in

the illustration until it stops. Confi rm the powder cap is

fi rmly attached and the triangle symbol on the powder

cap lies within the range of the mounting position mark.

In case the triangle symbol lies outside of the mounting

position mark, replace your powder seal with new one

according to “10.4 Replacement of powder seal”.

Remove water, oil,

and powder.

Enlarged sectional view

Groove

Powder seal

Mounting position mark

Triangle symbol

Loading...

Loading...