34

10. REPLACEMENT OF CONSUMABLE PARTS, DISPOSAL

* For disposal of used consumables, see “10.5 Disposal”

10.1 Replacement of head

The nozzle of the head will wear out with use. A broadened

spraying orifi ce will cause decrease in cleaning effi ciency and

diffi culty in pinpoint spraying. When the spraying orifi ce

has become larger like shown in the illustration, the work

effi ciency will be recovered by replacement of the head

(separately available). Attach the head properly according to

“7.3 Attaching head” when replacing.

* The entire head must be replaced, not only the nozzle.

10.2 Replacement of head o-ring

In case the o-ring at the coupling of the head is damaged or

worn or, air, water, or powder leaks from the joint, replace

the used o-ring with the provided head o-ring (spare). Attach

the o-ring properly in place. Do not damage the surface of

the o-ring when replacing.

10.3 Replacement of powder cap

The transparency of the powder cap will lower with use and may result in decreased visibility inside the powder cap. In case

you cannot see powder in the powder chamber, replace the powder cap (separately available). Attach the powder cap properly

according to the instructions in “7.4 Attaching powder cap” when replacing it.

34

10. REPLACEMENT OF CONSUMABLE PARTS, DISPOSAL

* For disposal of used consumables, see “10.5 Disposal”

10.1 Replacement of head

The nozzle of the head will wear out with use. A broadened

spraying orifi ce will cause decrease in cleaning effi ciency and

diffi culty in pinpoint spraying. When the spraying orifi ce

has become larger like shown in the illustration, the work

effi ciency will be recovered by replacement of the head

(separately available). Attach the head properly according to

“7.3 Attaching head” when replacing.

* The entire head must be replaced, not only the nozzle.

10.2 Replacement of head o-ring

In case the o-ring at the coupling of the head is damaged or

worn or, air, water, or powder leaks from the joint, replace

the used o-ring with the provided head o-ring (spare). Attach

the o-ring properly in place. Do not damage the surface of

the o-ring when replacing.

10.3 Replacement of powder cap

The transparency of the powder cap will lower with use and may result in decreased visibility inside the powder cap. In case

you cannot see powder in the powder chamber, replace the powder cap (separately available). Attach the powder cap properly

according to the instructions in “7.4 Attaching powder cap” when replacing it.

35

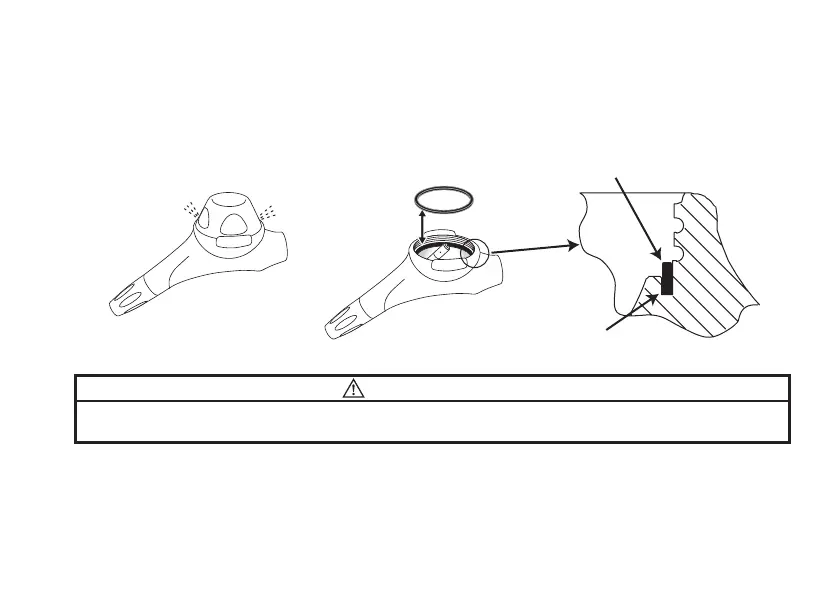

10.4 Replacement of powder seal

In case the powder seal attached into the thread of the powder chamber is damaged or worn or, air or powder leaks between the

powder cap and powder seal, replace the used powder seal with the provided powder seal (spare). Follow the procedure below:

If powder or something remains in the groove of the powder chamber, in which the powder seal is attached (see the illustration

below), remove it with air from a three-way syringe. Clean the groove and attach the powder seal properly so that the powder seal

fully seats in the groove (see the illustration below). Do not damage the surface of the powder seal when replacing.

CAUTION

When replacing o-rings and powder seal, be careful about the correct mounting location and direction. Incorrect mounting may

cause injuries due to disconnection of the head or powder cap, powder scattering, leakage of air, water, or powder during use.

10.5 Disposal

Dispose of this product according to your local rules and regulations.

Powder seal (spare)

Leak

Engage powder

seal fully in

the groove of

chamber unit.

Enlarged

sectional view

Groove

Powder seal

35

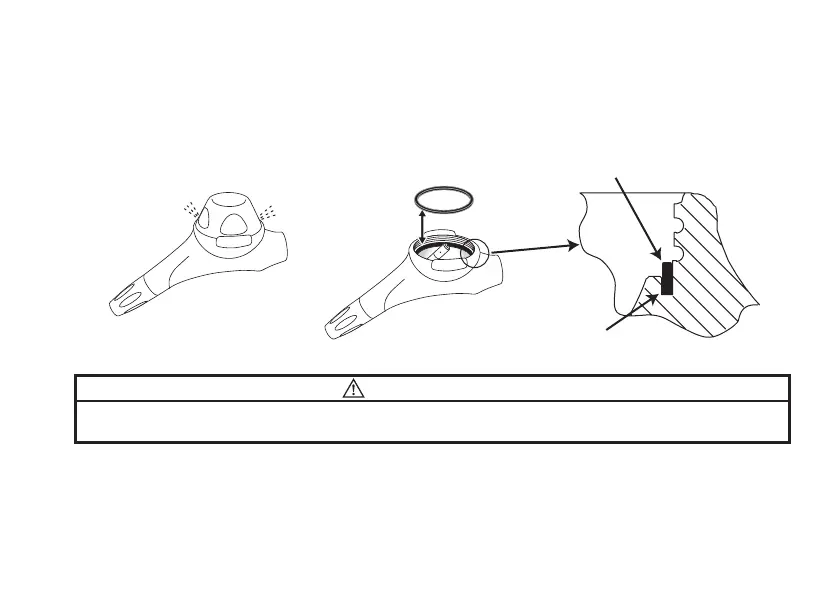

10.4 Replacement of powder seal

In case the powder seal attached into the thread of the powder chamber is damaged or worn or, air or powder leaks between the

powder cap and powder seal, replace the used powder seal with the provided powder seal (spare). Follow the procedure below:

If powder or something remains in the groove of the powder chamber, in which the powder seal is attached (see the illustration

below), remove it with air from a three-way syringe. Clean the groove and attach the powder seal properly so that the powder seal

fully seats in the groove (see the illustration below). Do not damage the surface of the powder seal when replacing.

CAUTION

When replacing o-rings and powder seal, be careful about the correct mounting location and direction. Incorrect mounting may

cause injuries due to disconnection of the head or powder cap, powder scattering, leakage of air, water, or powder during use.

10.5 Disposal

Dispose of this product according to your local rules and regulations.

Powder seal (spare)

Leak

Engage powder

seal fully in

the groove of

chamber unit.

Enlarged

sectional view

Groove

Powder seal

Loading...

Loading...