28

ATTENTION

1) Drain polisher before every sterilization and once a day after clinic hours.

2) Do not lubricate this product. Lubricant will be mixed into the compressed air and cause powder clogging.

5) Checking your air compressor

Check your air compressor referring to “7.1 4) Checking your air compressor”.

28

ATTENTION

1) Drain polisher before every sterilization and once a day after clinic hours.

2) Do not lubricate this product. Lubricant will be mixed into the compressed air and cause powder clogging.

5) Checking your air compressor

Check your air compressor referring to “7.1 4) Checking your air compressor”.

29

8.2 Cleaning at troubles in air and powder spray

In case of trouble in air and powder spray, clean each part of polisher. Cleaning must be done when polisher is disconnected

from the coupling on your turbine hose.

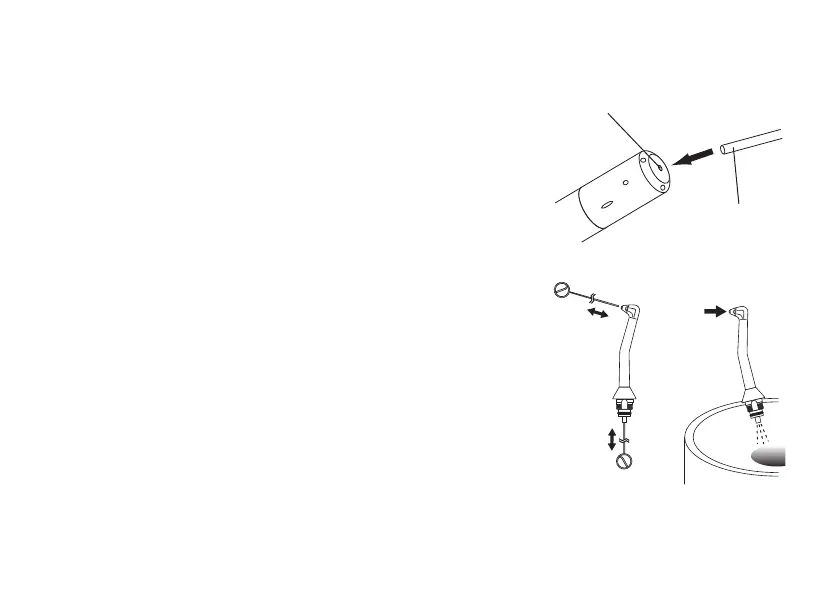

1) Powder stirring cap cleaning (if the center hole

of the stirring cap is clogged with powder)

(a) Remove powder adhered on the center hole of the

powder stirring cap with a cotton swab or dry cloth.

(b) Clean the center hole with the attached cleaning wire to

remove the powder blocking the center hole.

(The cleaning wire does not pass through the

center hole.)

2) Head cleaning

(a) Remove the head from the chamber unit.

(b) Insert the cleaning wire into the spraying orifi ce of the

nozzle and center hole of the coupling. Remove powder

remaining within the channels using the cleaning wire.

(c) Blow air into the spraying orifi ce of the nozzle with a

three-way syringe to remove powder remaining inside.

(d) If water, oil, or powder remains in the head, remove with

a cotton swab or dry cloth.

Center hole of powder stirring cap

Cleaning wire

Blow air

29

8.2 Cleaning at troubles in air and powder spray

In case of trouble in air and powder spray, clean each part of polisher. Cleaning must be done when polisher is disconnected

from the coupling on your turbine hose.

1) Powder stirring cap cleaning (if the center hole

of the stirring cap is clogged with powder)

(a) Remove powder adhered on the center hole of the

powder stirring cap with a cotton swab or dry cloth.

(b) Clean the center hole with the attached cleaning wire to

remove the powder blocking the center hole.

(The cleaning wire does not pass through the

center hole.)

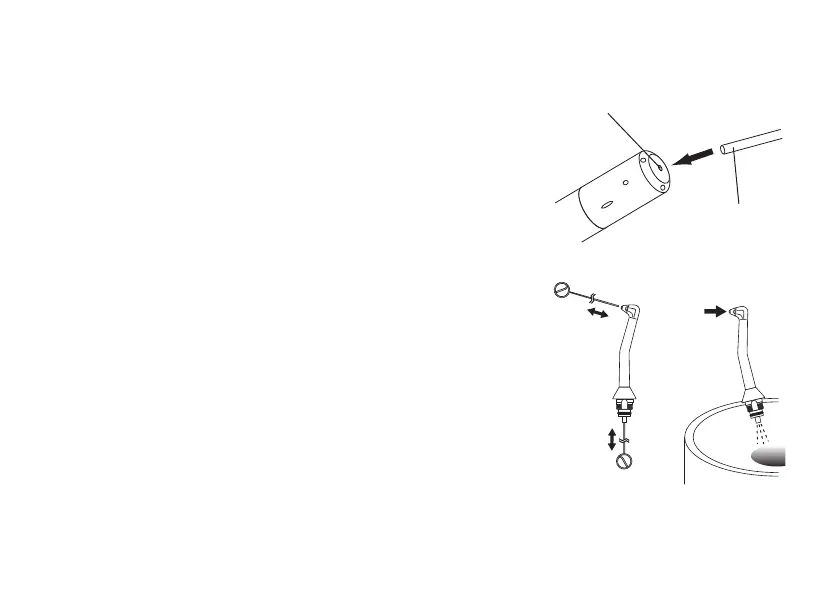

2) Head cleaning

(a) Remove the head from the chamber unit.

(b) Insert the cleaning wire into the spraying orifi ce of the

nozzle and center hole of the coupling. Remove powder

remaining within the channels using the cleaning wire.

(c) Blow air into the spraying orifi ce of the nozzle with a

three-way syringe to remove powder remaining inside.

(d) If water, oil, or powder remains in the head, remove with

a cotton swab or dry cloth.

Center hole of powder stirring cap

Cleaning wire

Blow air

Loading...

Loading...