26

8. MAINTENANCE AND CHECKS

8.1 Regular maintenance and checks

* Perform maintenance and checks as follows before sterilization and after clinic hours without fail.

ATTENTION

To use safely, check and maintain this product daily after clinic hours according to the instructions in “8. MAINTENANCE

AND CHECKS”.

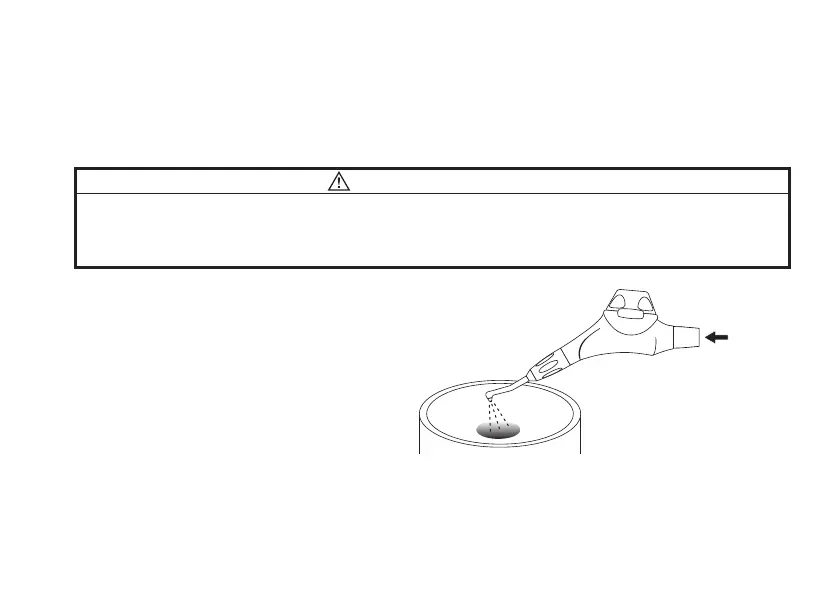

1) Powder disposal

Detach the powder cap referring to “7.10 3) Detaching powder cap”. Taking care of powder scattering, discard the leftover

powder.

ATTENTION

The leftover powder must be discarded after treatment. When the powder gets damp, it will cause clogging.

2) Removal of remaining powder within polisher

(a) Attach the emptied powder cap to the chamber unit.

(b) Connect polisher to the coupling on your turbine hose.

(c) Direct the nozzle to your cuspidor. Depress your foot

control without water supply from the dental unit. Run for

1 minute to remove the powder remaining within the

channels of polisher.

(d) Disconnect polisher from your coupling.

Stop water supply.

Idle run for 1 min.

26

8. MAINTENANCE AND CHECKS

8.1 Regular maintenance and checks

* Perform maintenance and checks as follows before sterilization and after clinic hours without fail.

ATTENTION

To use safely, check and maintain this product daily after clinic hours according to the instructions in “8. MAINTENANCE

AND CHECKS”.

1) Powder disposal

Detach the powder cap referring to “7.10 3) Detaching powder cap”. Taking care of powder scattering, discard the leftover

powder.

ATTENTION

The leftover powder must be discarded after treatment. When the powder gets damp, it will cause clogging.

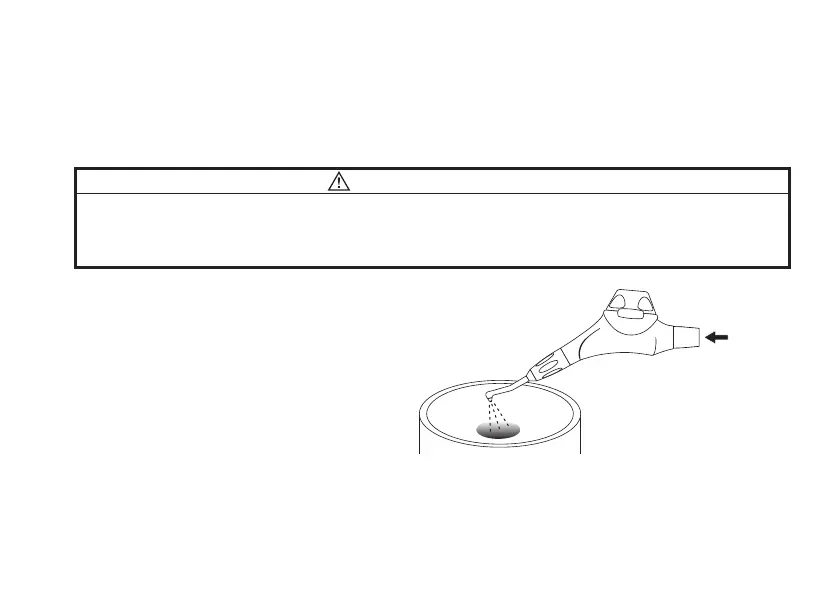

2) Removal of remaining powder within polisher

(a) Attach the emptied powder cap to the chamber unit.

(b) Connect polisher to the coupling on your turbine hose.

(c) Direct the nozzle to your cuspidor. Depress your foot

control without water supply from the dental unit. Run for

1 minute to remove the powder remaining within the

channels of polisher.

(d) Disconnect polisher from your coupling.

Stop water supply.

Idle run for 1 min.

27

3) Cleaning and disinfection

(a) Remove the head and powder cap from the chamber unit.

(b) Scrub the chamber unit, head and powder cap in every part using a tooth brush thoroughly under warm running water at

< 38°C (100.4°F).

(c) Rinse thoroughly and confi rm no debris or blood remain.

(d) Remove remaining water by blowing air with a three-way syringe.

(e) Wipe the chamber unit, head and powder cap in every part with disinfectant alcohol.

ATTENTION

1) Do not use ultrasonic cleaners to clean this product. This will cause malfunction or damage.

2) Remove powder remaining inside and on the surface of polisher before every sterilization and after each treatment. The

powder is easy to adhere and remain in the powder chamber and thread, powder seal and thread of the powder cap. Clean

these parts in particular carefully. If the powder gets damp, it will cause clogging and powder adherence.

4) Water draining

(a) Attach the powder cap and head to the emptied chamber

unit.

(b) Direct the nozzle to your cuspidor. Blow air into the joint

of chamber unit with a three-way syringe to drain the

water channels.

Blow air.

27

3) Cleaning and disinfection

(a) Remove the head and powder cap from the chamber unit.

(b) Scrub the chamber unit, head and powder cap in every part using a tooth brush thoroughly under warm running water at

< 38°C (100.4°F).

(c) Rinse thoroughly and confi rm no debris or blood remain.

(d) Remove remaining water by blowing air with a three-way syringe.

(e) Wipe the chamber unit, head and powder cap in every part with disinfectant alcohol.

ATTENTION

1) Do not use ultrasonic cleaners to clean this product. This will cause malfunction or damage.

2) Remove powder remaining inside and on the surface of polisher before every sterilization and after each treatment. The

powder is easy to adhere and remain in the powder chamber and thread, powder seal and thread of the powder cap. Clean

these parts in particular carefully. If the powder gets damp, it will cause clogging and powder adherence.

4) Water draining

(a) Attach the powder cap and head to the emptied chamber

unit.

(b) Direct the nozzle to your cuspidor. Blow air into the joint

of chamber unit with a three-way syringe to drain the

water channels.

Blow air.

Loading...

Loading...