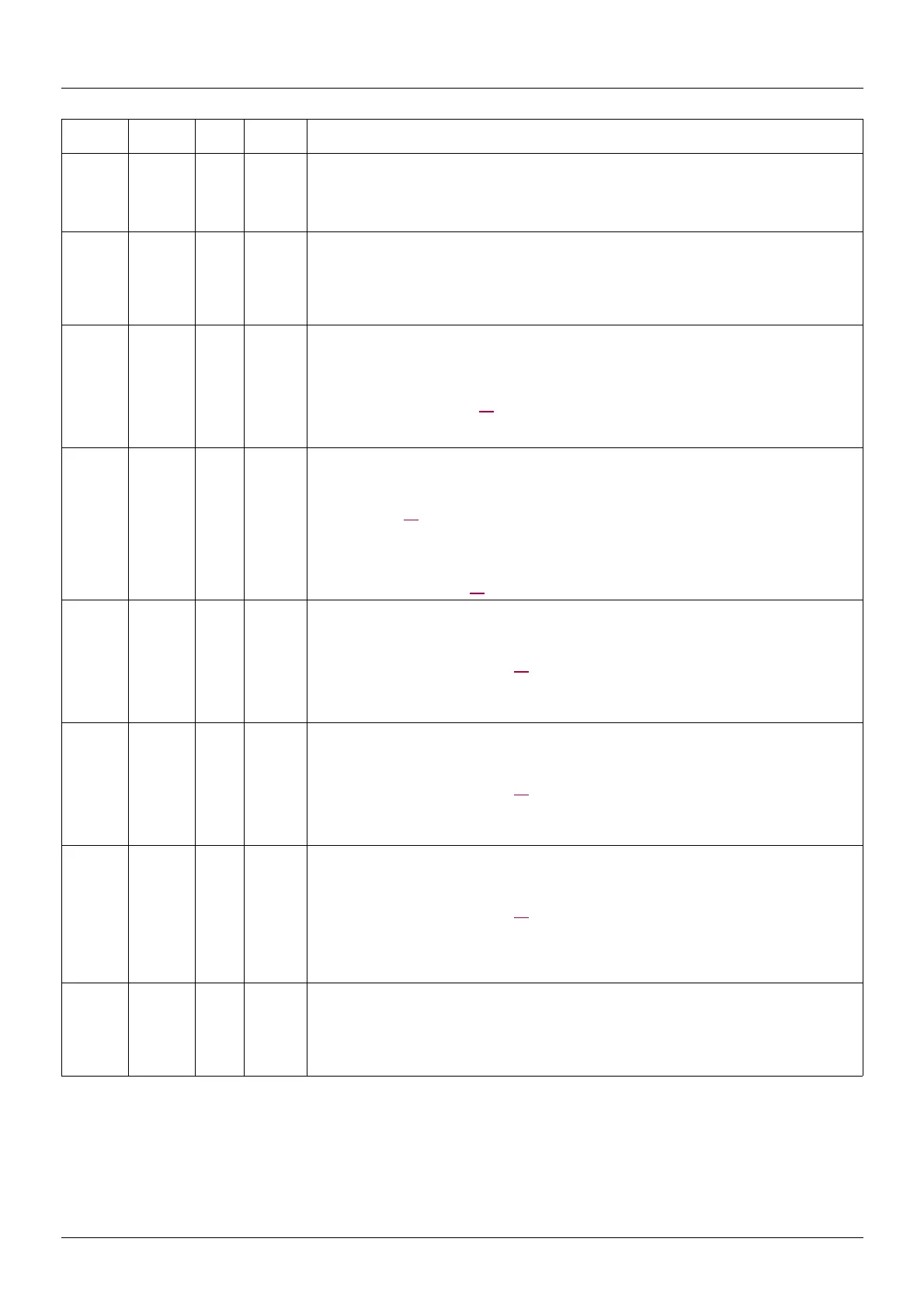

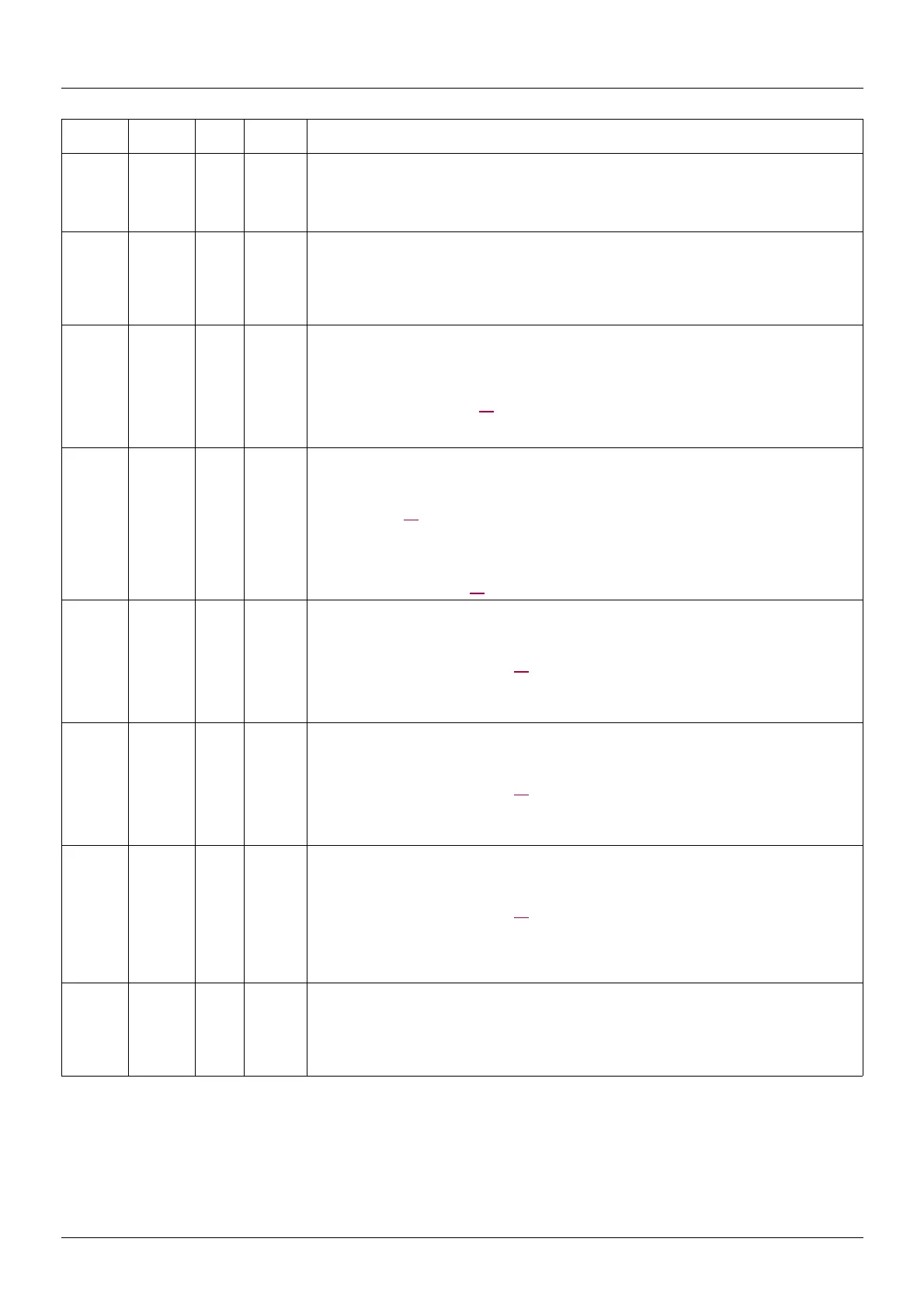

27

Configuration and adjustment variables

Modbus

address

CANopen

address

Code

Read/

Write

Name/Description/Possible values

3105 2001 / 6 LSP R/W Low speed

Unit: 0.1 Hz

Factory setting: 0

Adjustment range: 0 to HSP

(Motor frequency at min. reference)

3104 2001 / 5 HSP R/W High speed

Unit: 0.1 Hz

Factory setting: if bFr = 50: 500, if bFr = 60: 600

Adjustment range: LSP to tFr

(Motor frequency at max. reference): Ensure that this setting is suitable for the motor and the

application.

9622 2042 / 17 ItH R/W Motor thermal protection - max. thermal current

Unit: 0.1 A

Factory setting: According to drive rating

Adjustment range: 0.2 to 1.5 In (1)

Set ItH to the nominal current on the motor rating plate.

Please refer to OLL on page 53 if you wish to suppress thermal protection.

(1)In corresponds to the nominal drive current indicated in the Installation Manual and on the

drive rating plate.

9623 2042 / 18 UFr R/W IR compensation/Voltage boost

Unit: 1%

Factory setting: 20

Adjustment range: 0 to 100

- For UFt (page 31) = n or nLd: IR compensation

- For UFt = L or P: Voltage boost

Used to optimize torque at very low speed (increase UFr if the torque is insufficient).

Check that the value of UFr is not too high for when the motor is warm (instabilities can occur).

Note: Modifying UFt (page 31) will cause UFr to return to the factory setting (20%).

9620 2042 / 15 FLG R/W Frequency loop gain

Unit: 1%

Factory setting: 20

Adjustment range: 1 to 100

Parameter active only if UFt (page 31) = n or nLd.

The FLG parameter adjusts the following of the speed ramp on the basis of the inertia of the

machine being driven.

Too high a gain may result in operating instability.

9621 2042 / 16 StA R/W Frequency loop stability

Unit: 1%

Factory setting: 20

Adjustment range: 1 to 100

Parameter active only if UFt (page 31) = n or nLd.

Used to adapt the return to steady state after a speed transient (acceleration or deceleration),

according to the dynamics of the machine.

Gradually increase the stability to avoid any overspeed.

9625 2042 / 1A SLP R/W Slip compensation

Unit: 1%

Factory setting: 100

Adjustment range: 0 to 150

Parameter active only if UFt (page 31) = n or nLd.

Used to adjust the slip compensation value fixed by nominal motor speed.

The speeds given on motor rating plates are not necessarily exact.

If slip setting < actual slip: the motor is not rotating at the correct speed in steady state.

If slip setting > actual slip: the motor is overcompensated and the speed is unstable.

11301 2053 / 2 JPF R/W Skip frequency

Unit: 0.1 Hz

Factory setting: 0

Adjustment range: 0 to 5000

Used to avoid prolonged operation at a frequency range of ± 1 Hz around JPF. This function

helps to prevent a speed which leads to resonance. Setting the function to 0 renders it inactive.

Loading...

Loading...