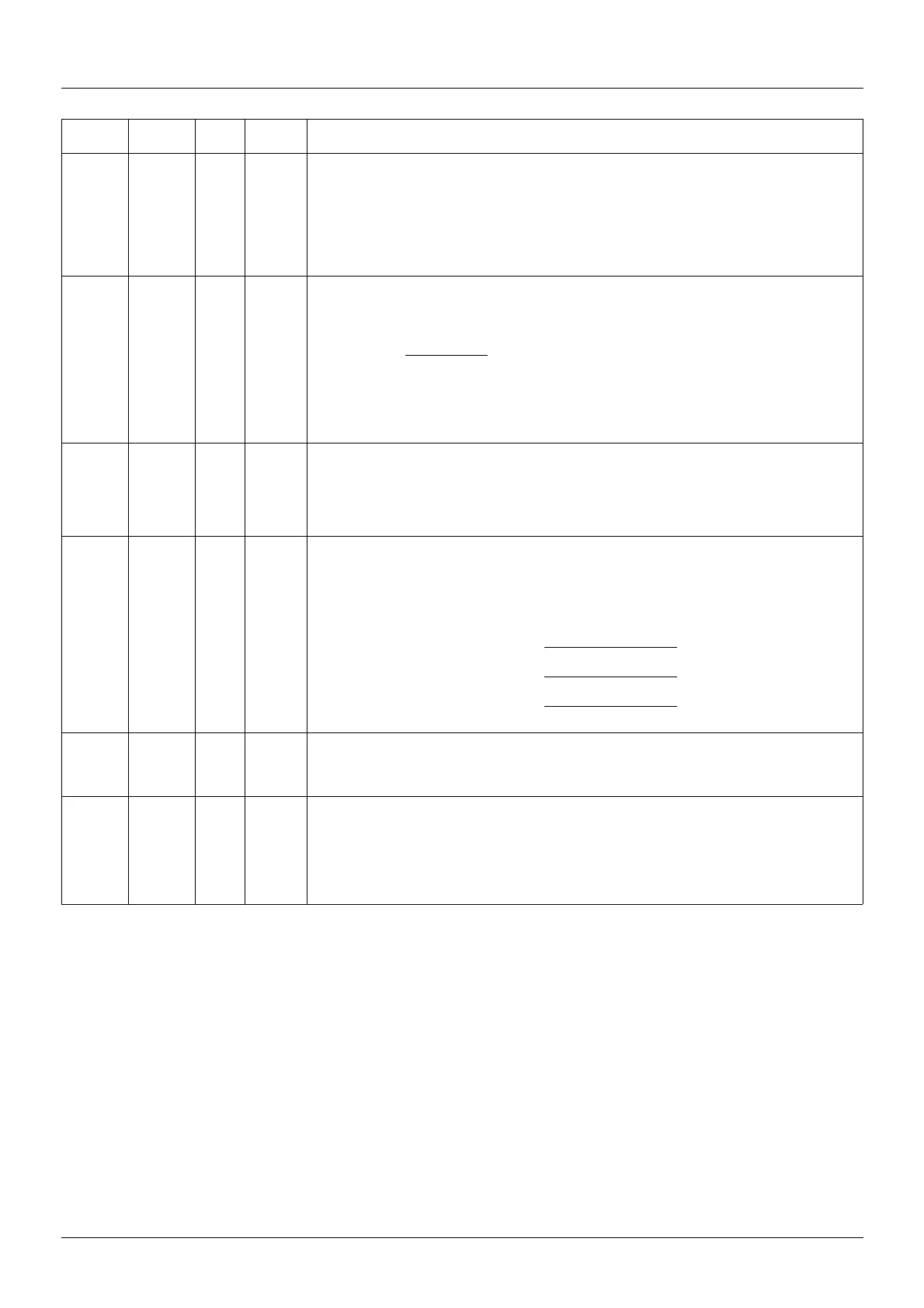

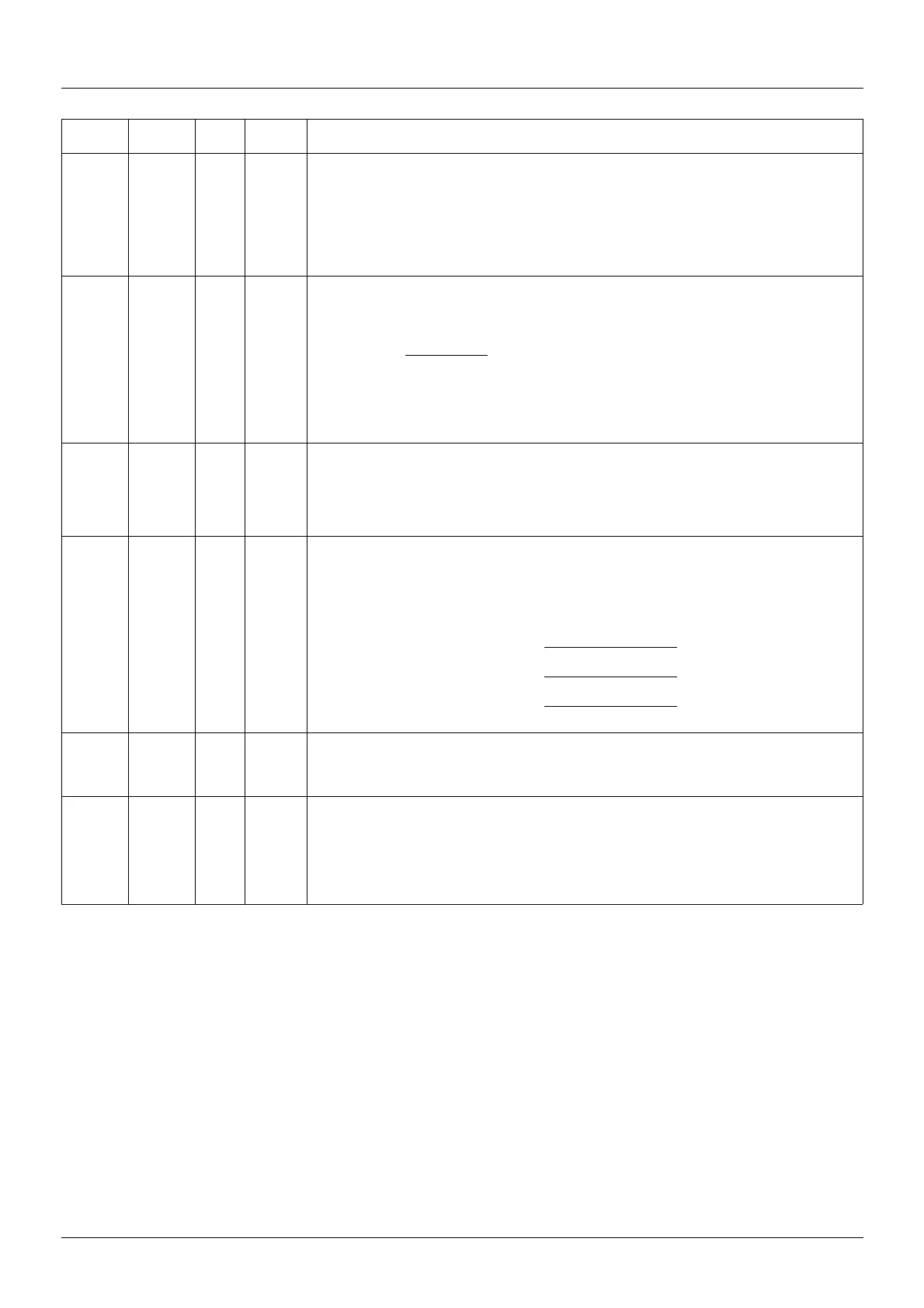

49

Configuration and adjustment variables

Modbus

address

CANopen

address

Code

Read/

Write

Name/Description/Possible values

9701 2043 / 2 UnS2 R/WS Nominal motor voltage (motor 2) given on the rating plate

Unit: 1 V

Factory setting: According to drive rating

Adjustment range: According to drive rating:

ER23-...K: 100 to 240 V

ER23-.../3K: 100 to 240 V

ER23-.../4K: 100 to 500 V

ER23-...6K: 100 to 600 V

9702 2043 / 3 FrS2 R/WS Nominal motor frequency (motor 2) given on the rating plate

Unit: 0.1 Hz

Factory setting: if bFr = 50: 500 if bFr = 60: 600

Adjustment range: 100 to 5000

Note: The ratio must not exceed the following values:

ER23-...K: 7 max.

ER23

-.../

3K: 7 max.

ER23

-.../

4K: 14 max.

ER23

-.../

6K: 17 max.

9703 2043 / 4 nCr2 R/WS Nominal motor current (motor 2) given on the rating plate

Unit: 0.1 A

Factory setting: According to drive rating

Adjustment range: 0.25 to 1.5 In (1)

(1)In corresponds to the nominal drive current indicated in the Installation Manual and on the

drive rating plate.

9704 2043 / 5 nSP2 R/WS Nominal motor speed (motor 2) given on the rating plate

Unit: 1 rpm

Factory setting: According to drive rating

Adjustment range: 0 to 32767

If, rather than the nominal speed, the rating plate indicates the synchronous speed and the slip

in Hz or as a %, calculate the nominal speed as follows:

Nominal speed = Synchronous speed x

or

Nominal speed = Synchronous speed x (50 Hz motors)

or

Nominal speed = Synchronous speed x (60 Hz motors)

9706 2043 / 7 COS2 R/WS Motor Cos Phi (motor 2) given on the rating plate

Unit: 0.01

Factory setting: According to drive rating

Adjustment range: 50 to 100

9707 2043 / 8 UFt2 R/W Selection of the type of voltage/frequency ratio for motor 2

Factory setting: 2

0 = "L": Constant torque for motors connected in parallel or special motors

1 = "P": Variable torque for pump and fan applications

2 = "n": Sensorless flux vector control for constant torque applications

3 = "nLd": Energy saving, for variable torque applications not requiring high dynamics (behaves

in a similar way to the P ratio at no load and the n ratio on load).

UnS (in volts)

FrS (in Hz)

Loading...

Loading...