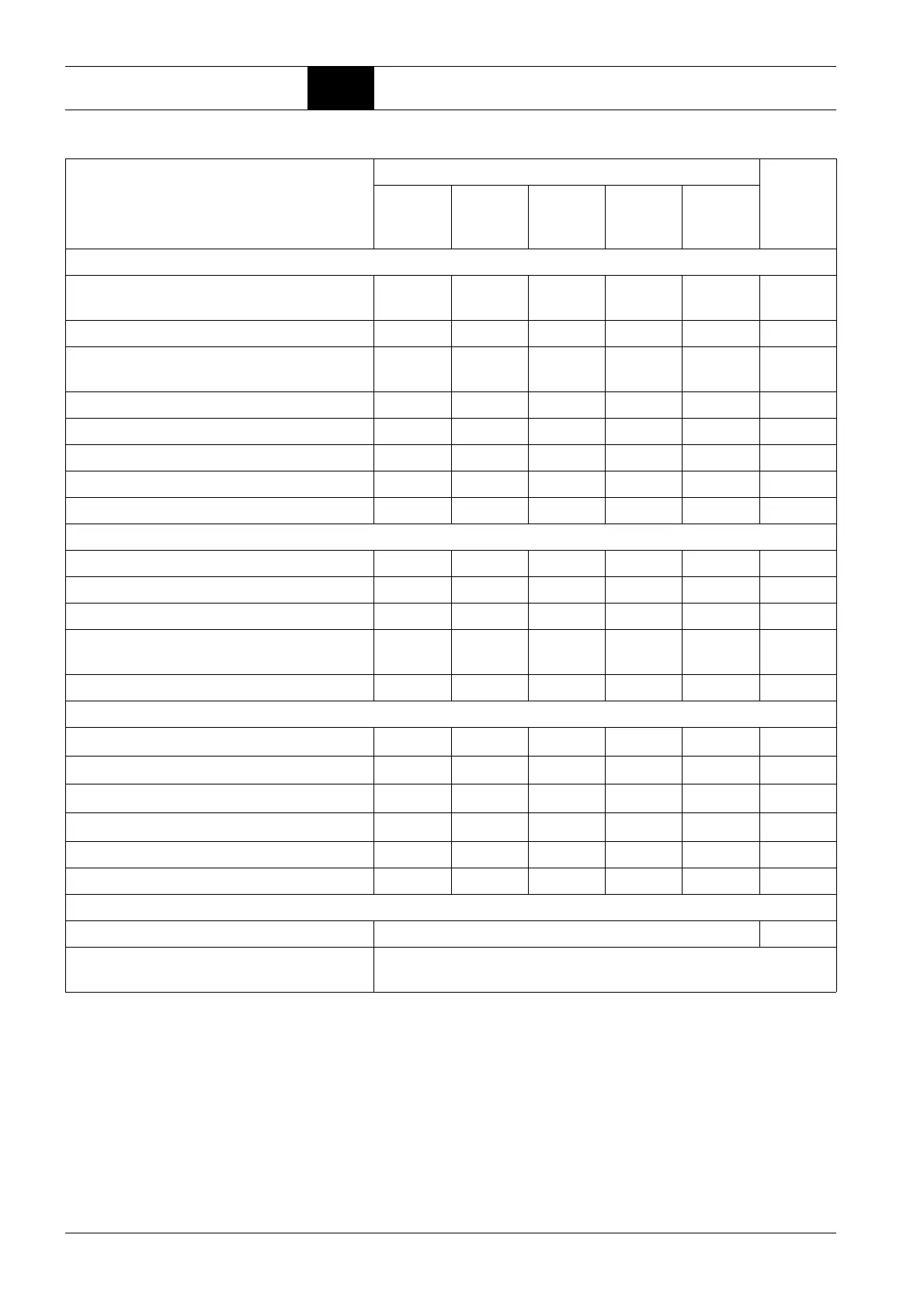

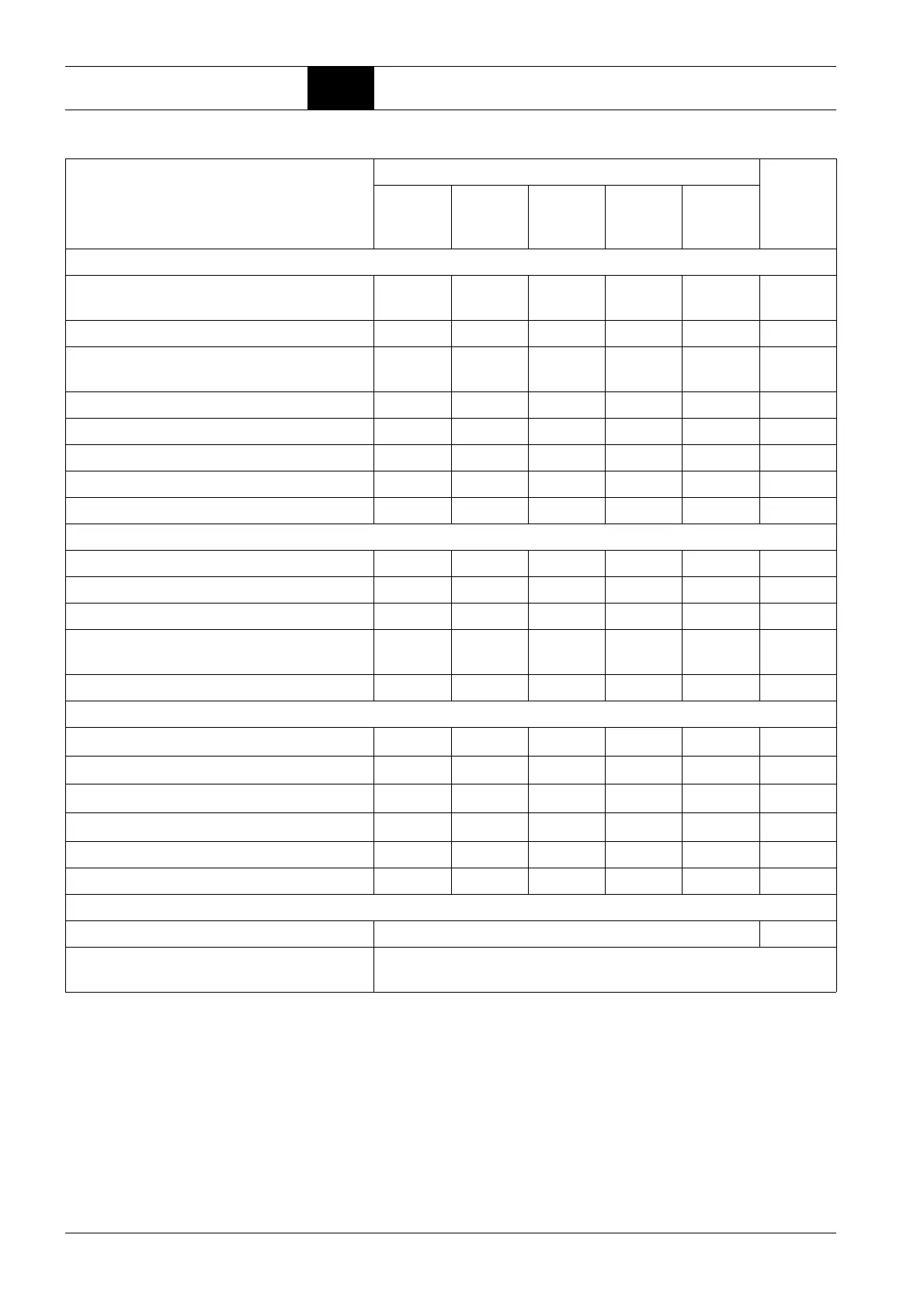

Maintenance 5.2 General

Page 34 BOGE Operating instructions for C 10 L...C 20 L series screw compressors

Maintenance work Maintenance intervals in operating hours

1)

Page

weeky,

monthly

1,000

annually

1,500

annually

3,000

annually

9,000

every

2 years

General maintenance work

Check final compression temperature

(set point value: 158...212°F)

w Control

Check compressor for leaks X –

Check system relief on system pressure gauge (22)

(set point value: 0...22 psig)

w Control

Check function of EMERGENCY STOP button m -

Clean oil cooler X 44

Draining off condensate from compr. air receiver w –

Check automatic condensate drainage w –

Check if electrical connections are tightened X –

Air circuit

Check and if necessary clean suction filter m 37

Change suction filter cartridge X 37

Check safety valve X 45

Replace minimum pressure valve

(wearing parts set)

X –

Replace suction controller X –

Oil circuit

Check oil level and top up as required

2)

X 38

Change oil separator

2)

X 40

Change oil filter

2)

X 39

Change oil

2)

X 42

Replace oil regulator (wearing parts set) X –

Replace nozzle with dirt catch X 45

Drive

Lubricate drive motor bearings Drive motors with permanent lubrication 38

Replace motor bearing Depending on mains frequency: 50 Hz 10,000 operating hours

60 Hz 8,000 operating hours

1)

If the compressor is not often used, undertake the maintenance according to the specified intervals (weekly/monthly/annually) depending on the number of operating

hours.

2)

The specified intervals only apply when BOGE compressor oil Syprem 8000 S is used! The service life may differ depending on the ambient temperature. In this case

have the oil analyzed by your BOGE service!

Table 5.1: Maintenance intervals

Loading...

Loading...