BT50/BT60/BT65BOMAG20

4.1 General

Pay careful attention to all applicable safety

regulations, especially the safety regulations in

section 2 of these operating, maintenance and

repair instructions when carrying out main-

tenance work.

Thorough maintenance of the tamper ensures

maximum reliability and prolongs the lifetime of

important components. The work involved is small

when compared with the problems which may

occur by not observing these instructions.

•

Clean tamper and engine thoroughly.

•

Place the tamper on level ground to carry out

maintenance work.

•

Carry out maintenance work only with the engine

shut down.

•

Always catch running out oils and fuels envi-

ronmentally and do not let them seep into the

ground. Dispose of oils and fuels environmen-

tally.

Frequent reasons for failures:

•

Faulty operation

•

Incorrect, insufficient maintenance

If you can not identify the cause of a failure by

following the trouble shooting chart or are not able

to eliminate the fault immediately yourself, consult

one of our service stations at our branch offices or

dealers.

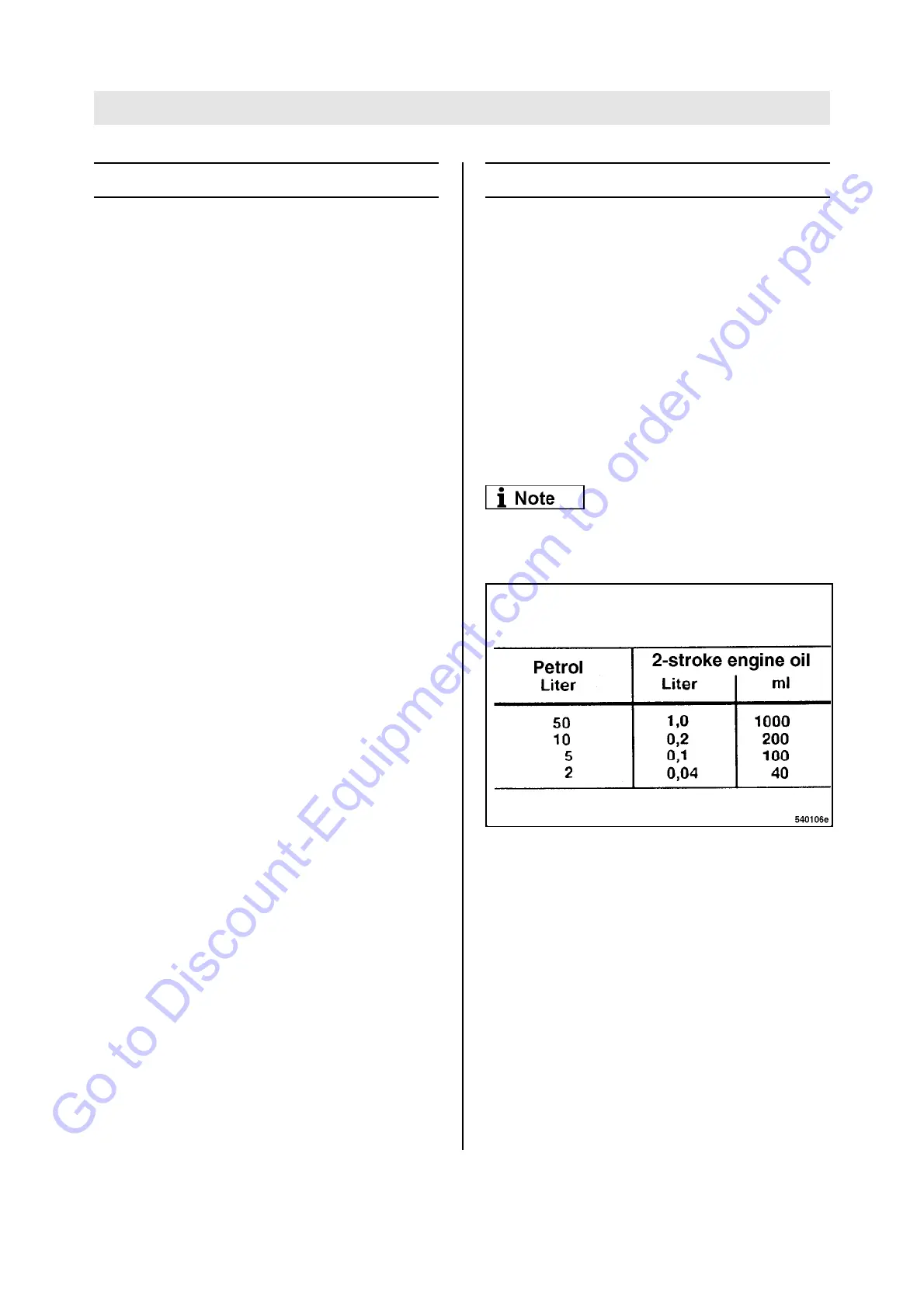

4.2 Fuels and lubricants

Fuel

Quality

Use only commercially available brand carburettor

fuel.

Use only unleaded standard grade gasoline and

mix it with two stroke engine oil at a mixing ratio of

50:1.

Two stroke engine oil

Use only two stroke engine oil.

Oil with self-mixing properties may also be used.

Unsuitable oil causes premature carbon deposits

in the exhaust channel of the engine.

Fig. 1

Oil in tamper foot

Use engine oil SAE 90 API GL5.

Maintenance

Go to Discount-Equipment.com to order your parts

Loading...

Loading...