Voorhout • Groningen • Weert • Hoogerheide T +31(0)88 7865800 I elsto.eu

05/2013 39 Quick Start Guide

Agile

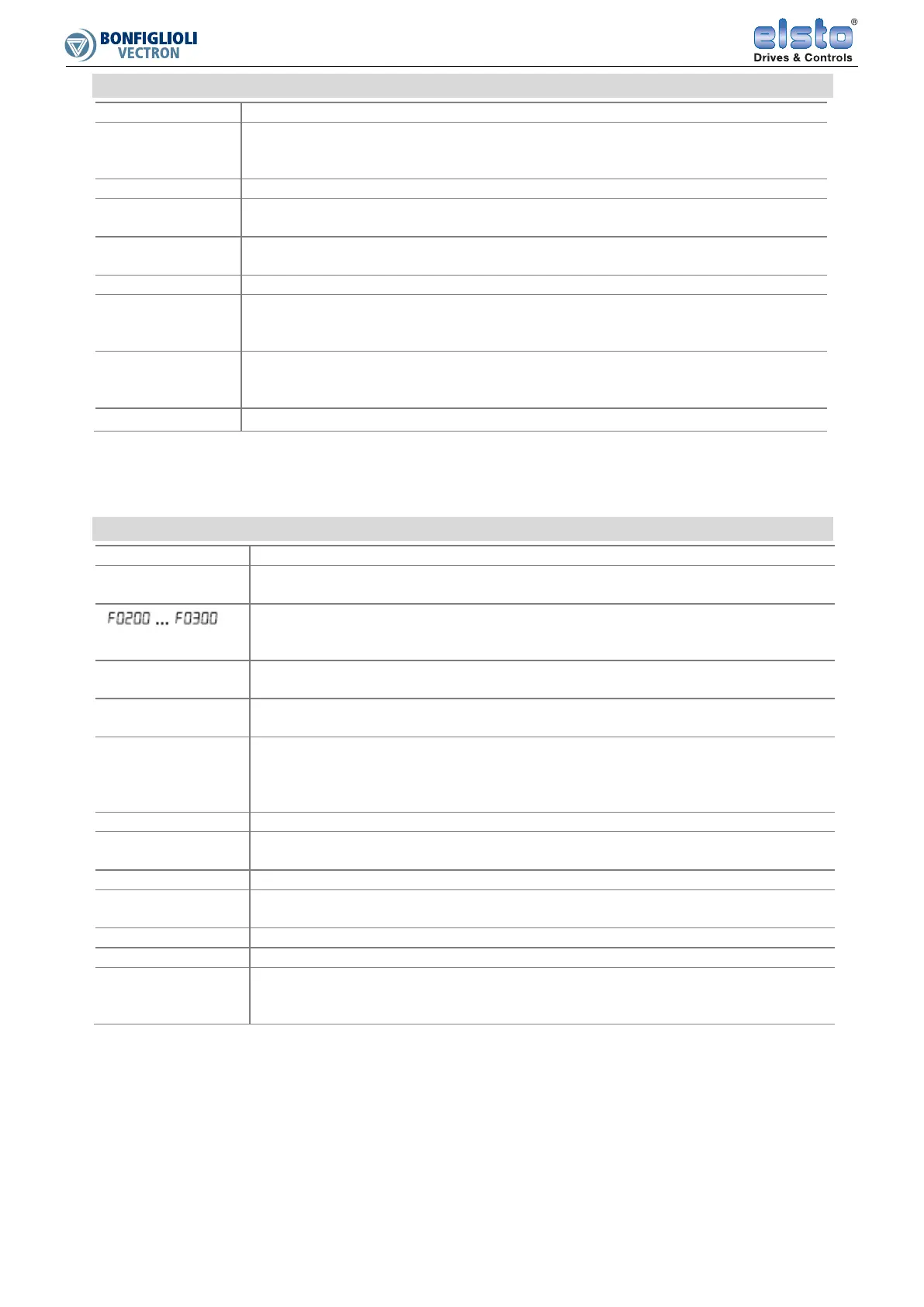

Error messages and warnings during setup

Error messa

es Fault clearance

Check rated motor values in parameters 370…376. Correct the values if

necessary. Repeat Setup. Check motor cable connections and frequency inverter

connections.

Warnin

s

Check rated motor values in parameters . Correct the values if

necessary. Repeat Setup.

The followin

causes are possible: The motor cable cros- section is not sufficient.

The motor cable is too long. The motor cable is not connected correctly.

Check P372 (rated speed), P375 (rated frequency).

The machine data for star connection is entered, but the motor is connected in

delta. For star connection change the motor cable connection. For delta connec-

tion check the entered rated motor values. Repeat Setup.

The machine data for delta connection is entered, but the motor is connected in

star. For delta connection change the motor cable connection. For star connection

check the entered rated motor values. Repeat Setup.

Check motor connection and frequency inverter connections.

- Press ESC to correct a parameter value after an error message or after a warning message.

- Press ENT to ignore a warning message. Setup is continued. It is recommended to check

the entered data.

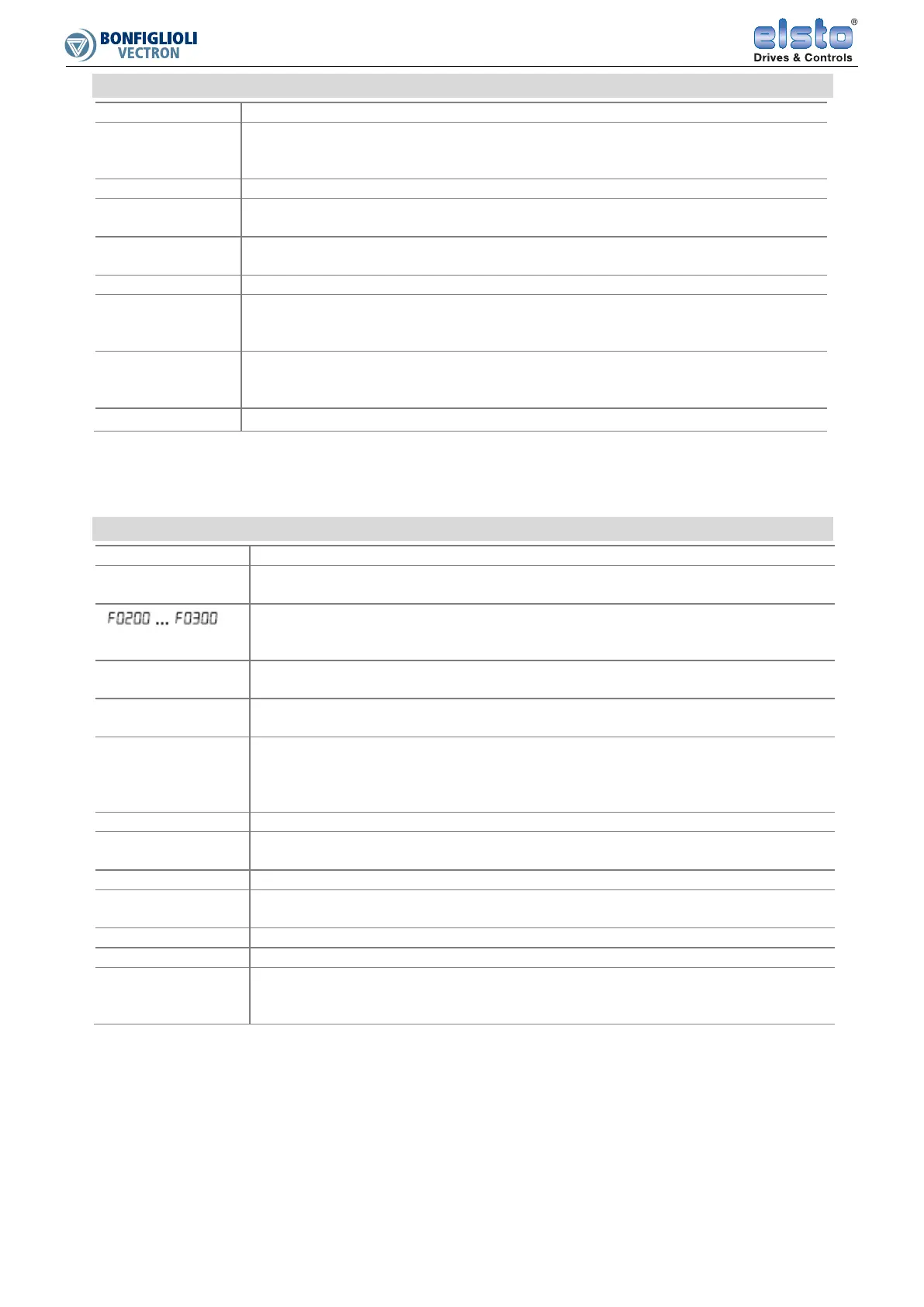

Error messages and warnings during operation

Error messa

es Fault clearance

Frequency inverter overloaded. Check load behavior. Check motor parameter

settings.

Overtemperature. Check coolin

, fan, sensor and ambient temperature.

Low temperature. Check ambient temperature and electrical cabinet heating.

Motor temperature too hi

h or sensor defective. Check connection on X.12.4.

Phase failure. Check motor and wiring.

Overloaded, short circuit or earth fault, motor current or phase failure. Check load

behavior and ramps (P420 … P423). Check motor and wiring.

DC link volta

e too hi

h or too low. Check deceleration ramps (P421, P423) and

the connected brake resistor. Check mains voltage.

Power failure or phase failure, voltage brake- chopper or motor chopper too high.

Check mains voltage, mains fuses and circuit.

Electronic volta

e (DC 24V) too hi

h or too low. Check wirin

of control terminals.

Maximum frequency achieved. Check control si

nals an settin

s.

Check deceleration ramps P421, P423) and the connected brake resistor.

F1201 F1204...

Internal STO-error. Please use the instruction manual for details.

F 120

Enable si

nals STOA and STOB were not actuated at the same time, but with a

time offset bigger than 5 seconds. Check the circuitry of the enable input signals.

F1206 F1209...

Internal STO-error. Please use the instruction manual for details.

Minimum output current. Check motor and wirin

.

Reference value si

nal on input X12.3 faulty, check si

nal.

Overcurrent on input X12.3, check signal.

Overcurrent on input X12.4, check signal.

1

1

F0400 F040

...

F0700 F070

...

F0801 F080

11

111

...

F131

14

F1407

F140

SA001 SA00

...

SF001 SF02

...

SA021

,

SA02

SA041 SA04

SA05

Loading...

Loading...