Water-To-Water Unit Controller | 24Greensource CDi Series TW Model

8733954853 (2020/04)Greensource CDi Series TW Model

Subject to change without prior notice

A 120-second time delay is built into the

low-pressure switch to avoid nuisance trips with

low-fluid temperatures. While in a soft-lockout

condition the display will show the specific fault

(for example LP1) and the “service” LED will turn

on according to the malfunction mode. If the

setting for malfunction mode is “steady,” the

service LED will turn and remain on. If the setting

is “pulse,” the service LED will blink according to

the blink code as follows:

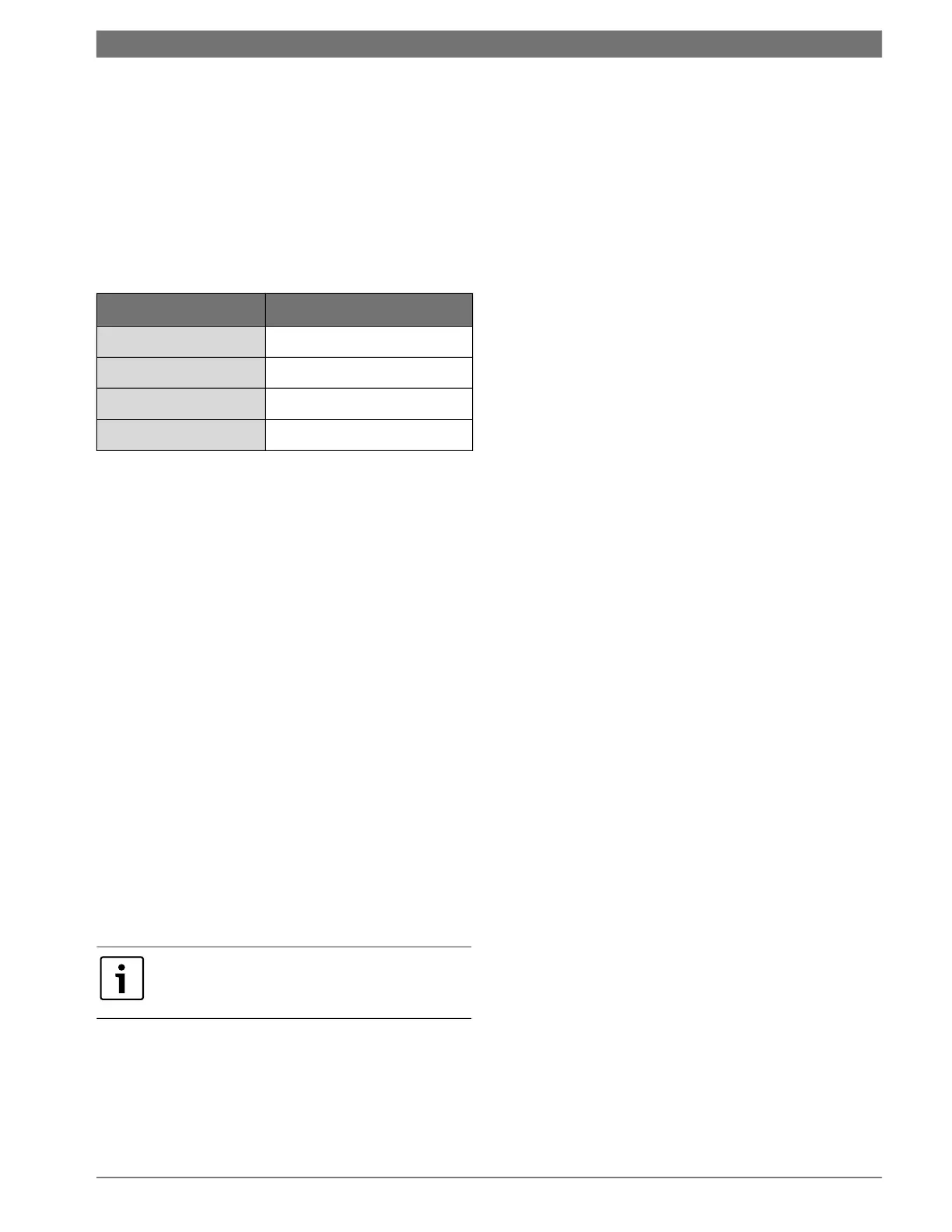

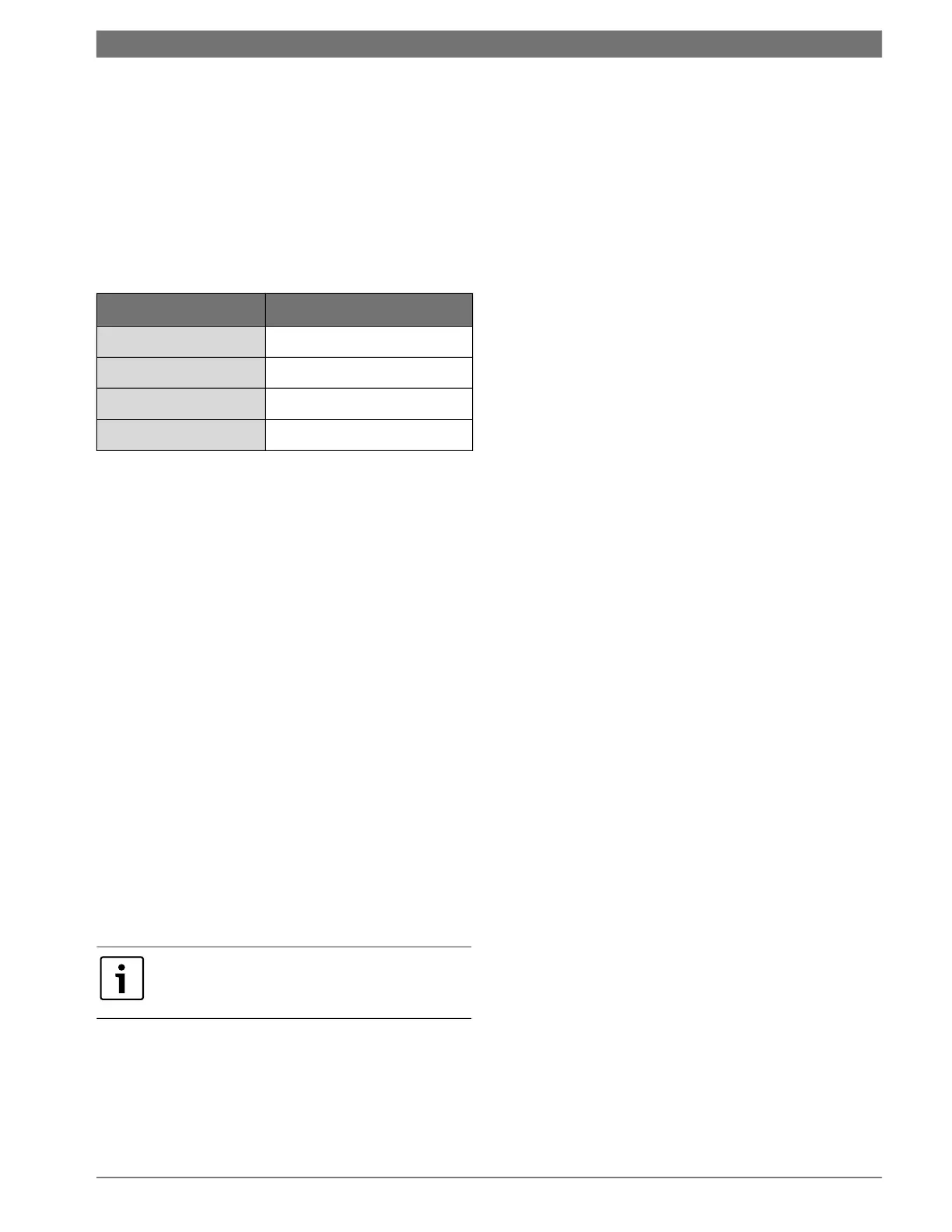

Table 5 Blink code

Brownout Protection

The control will disable all outputs if the supply

voltage drops below 17 VAC. The outputs will be

enabled if the supply voltage rises and remains

above 17 VAC for the five-minutes time delay.

During that time, the control will display “bro.”

Manual Lockout

The unit or refrigeration circuit will go into a

manual lockout if the HPS or LPS opens (LPS open

more than 120 seconds each time) twice within

one hour. During manual lockout the

compressor(s) is turned off and locked out and the

display will show the fault (for example LP1) and

the “service” LED “malfunction” output will either

be steady or blink according to the malfunction

mode as described above. If selection for

compressor is “Du” (see configuration) and one

compressor has locked out, the control will switch

the call to the other compressor. If compressor

setting is “Si,” the control shall not switch the call

to the other compressor.

Pump Cycling

When ordered with the optional pump relay, the

controller will cycle either the load, source, or both

pumps with the compressor operation. Please see

the wiring diagrams on page #35 through page #40.

Operating Instructions

Refer to Fig. 13 on page #22.

User Interface

The following parameters are displayed on the

screen:

• Control fluid temperature when in normal

mode

• Settings within the configuration mode

• Individual operating mode temperature set

points

• Fault display

UP Button

• Press once to display the current set-point

temperature.

• After the current set-point temperature is

displayed, pressing again will increment the

set point 1 degree for every push. Pressing and

holding the UP button increments the set point

at a rate of 4 degrees per second.

• When pressed with the DOWN arrow for 5

seconds, the control will display the current

temperature scale (Fahrenheit or Celsius).

• Used to change the settings for: temperature

scale, dead band, test mode, initial delay,

compressor, pump, and malfunction settings.

DOWN Button

• Press once to display the current set-point

temperature.

• After the current set-point temperature is

displayed, pressing again will decrement the

set point 1 degree for every push. Pressing and

holding the DOWN button will decrement the

set point at a rate of 4 degrees per second.

• When pressed with the UP arrow for 5

seconds, the control will display the current

temperature scale (Fahrenheit or Celsius).

• Used to change the settings for: temperature

scale, dead band, test mode, initial delay,

compressor, pump, and malfunction settings.

Blink Code Fault Condition

ONE BLINK

High-Pressure Circuit 1

TWO BLINKS

Low-Pressure Circuit 1

THREE BLINKS

High-Pressure Circuit 2

FOUR BLINKS

Low-Pressure Circuit 2

To reset a unit after a hard lockout, the user

needs to recycle power or switch the

controller to the OFF mode.

Loading...

Loading...