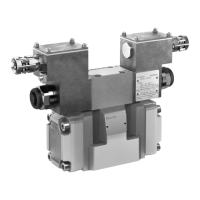

Assembly 33/52

RE24751-XE-B/10.19, H-4WEH...XE..., BoschRexrothAG

1.

Dismount the solenoid coil (seechapter7.7.4 "Rotating the solenoid coil by±90°").

2. Remove the plug screw (hexagon, wrench size22).

3. Remove the cable and line entry. To do this, unscrew the cable and line entry

from the double nipple (2). Make sure not to lose the O-ring (1) between the

housing and double nipple.

4. Assemble the cable and line entry at the opposite side of the terminal box.

Tightening torque of the double nipple(2):

10...12Nm

5. Assemble the plug screw. Tightening torque of the plug screw 7...9Nm

6. Assemble the solenoid coil (seechapter7.7.4 "Rotating the solenoid coil by±90°").

7.7.4 Rotating the solenoid coil by ± 90°

WARNING

Explosion hazard caused by improper assembly!

Improper assembly will result in the loss of the explosion protection!

▶ Strictly observe the following modification instructions for turning the

valvesolenoid.

▶ A gap between valve housing and valve solenoid is not admissible.

▶ Ensure that every solenoid coil is re-assigned to the original valve.

Solenoid coils can be assembled in staggered assembly around the pole tube,

i.e.the longitudinal axis of the valve, displaced by ± 90°.

The pole tube of the valve solenoid is completely sealed towards the oil circuit.

The solenoid coil can therefore still be twisted if the valve has already been

installed.

1. Detach the mounting nut of the valve solenoid at the pole tube (hexagon nut,

wrench size32).

2. Remove the solenoid coil and the O-ring from the valve and rotate it by 90° in the

desired direction.

3. Re-attach the solenoid coil in the desired position. After the rotation of the

solenoid coil, the coil pin must engage in the bore of the valve housing.

4. Assemble the O-ring onto the pole tube and slide it forward up to the

solenoidcoil.

5. Re-tighten the mounting nut of the valve solenoid (hexagon nut, wrench size32,

tightening torque 4+1Nm). Afterwards, there must be no visible gap between

the solenoid coil and the valve housing.

Assembling the cable and

line entry on the opposite

side of the terminal box

Loading...

Loading...