Risk of damage to the

DC bus capacitor unit

KLC

from long-term storage!

The DC bus capacitor unit KLC contains electrolytic capacitors which may

deteriorate during storage. When storing the DC bus capacitor unit KLC for a

longer period of time, run it once a year for at least 1 hour at DC bus voltage

U

DC

.

Ambient and operating conditions - storage

Description Symbol Unit Value

Temperature range T

a_store

°C -20 … +55

Relative humidity % 5 … 95

Absolute humidity

g/m

3

1 … 29

Climatic category (IEC721) 1K3

Moisture condensation Not allowed

Icing Not allowed

Tab. 4-5: Ambient and operating conditions - storage

KSM: Storage times

Additional measures must be taken on commissioning to preserve proper

functioning – irrespective of the storage time which may be longer than the

warranty period of our products. However, this does not involve any

additional warranty claims.

Motors

Storage time / months

Measures for commissioning

> 1 > 12 > 60

■ ■ ■ Visual inspection of all parts to be damage-free

■ ■ ■ Resurface the holding brake

■ ■

Check the electric contacts to verify that they are free from

corrosion

■ ■ Let the motor run in without load for one hour at 800 ... 1000 rpm

■ ■

Measure insulation resistance. Dry the winding at a value of <

1kohm per volt rated voltage.

■ Replace bearing

■ Replace encoder

Tab. 4-6: Measures before commissioning motors that have been stored over

a prolonged period of time

48/407

General data and specifications

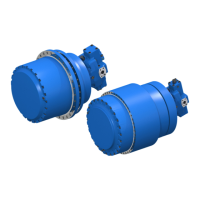

IndraDrive Mi Drive Systems with KCU02, KSM02,

KMS02/03, KMV03, KNK03, KLC03

Bosch Rexroth AG R911335703_Edition 04

Loading...

Loading...