Subject to change without prior notice Revised 05-12

6 720 220 046

16 TA Series

6. Close all valves and remove the drain hose.

7. Install HR water piping.

HR WATER PIPING:

All hot water piping should be a minimum of 3/8t

O.D. copper tube to a maximum distance of fteen

(15) feet. For distances beyond fteen feet but not

exceeding sixty (60) feet use 1/2” copper tube.

Separately insulate all exposed surface of both

connecting water lines with 3/8” wall closed cell

insulation. Install isolation valves on supply and

return to the heat recovery. (Figure #9)

WATER TANK REFILL:

1. Open the cold water supply to the tank.

2. Open a hot water faucet to vent air from the system

until water ows from the faucet, then close.

3. Depress the hot water tank pressure relief valve

handle to ensure there is no air remaining in the tank.

4. Carefully inspect all plumbing for water leaks.

Correct as required.

5. Purge all air from HR by depressing the schrader

valve on the HR Unit. Allow all air to bleed out

until water appears at the valve.

6. Before restoring the power or fuel supply to the

water heater, adjust the temperature setting on

the tank thermostat(s) to ensure maximum

utilization of the heat available from the

refrigeration system and conserve the most

energy. On tanks with both upper and lower

elements and thermostats, the lower element

should be turned down to 100° F, while the

upper element should be adjusted to 120° F.

Depending upon the specic needs of the

customer, you may need to adjust the upper

element differently. On tanks with a single

thermostat lower the thermostat setting to 120°

F or the “LOW” position.

7. After thermostat adjustments are completed,

replace access cover and restore electrical or

fuel supply to water heater.

INITIAL START-UP:

1. Make sure all valves in heat recovery water

piping system are open. NEVER OPERATE HR

PUMP DRY.

2. Turn on the heat pump. The HR pump should not

run if the compressor is not running.

3. Turn HR switch to the “ON” position. The pump

will operate if entering water temperature to HR

is below 120° F.

4. The temperature difference between the water

entering and leaving the heat recovery should be

5° to 15° F.

5. Allow the unit to operate for 20 to 30 minutes to

ensure it is functioning properly. The pump

should shut off when the water temperature

entering the heat recovery reaches 120°F.

Initial Start-UP

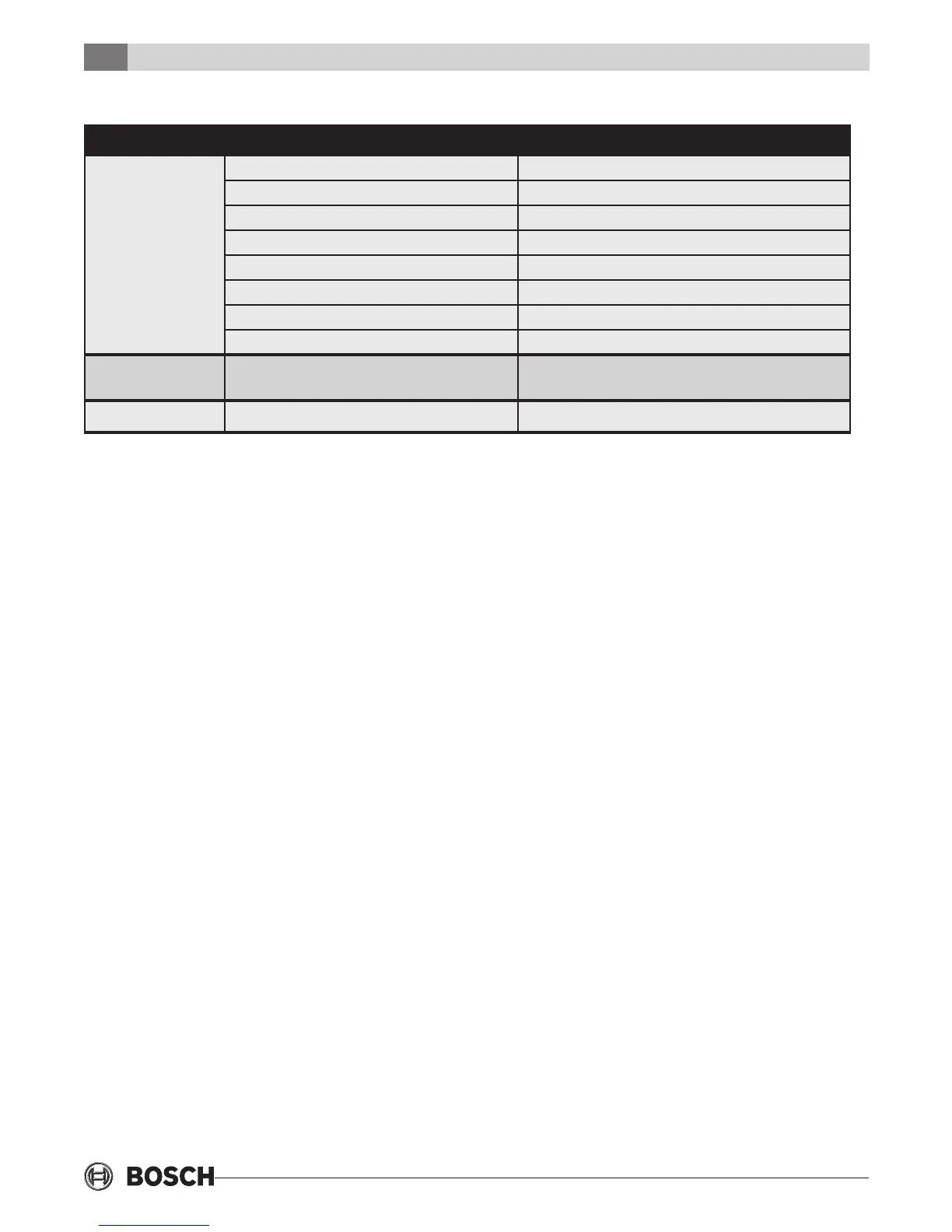

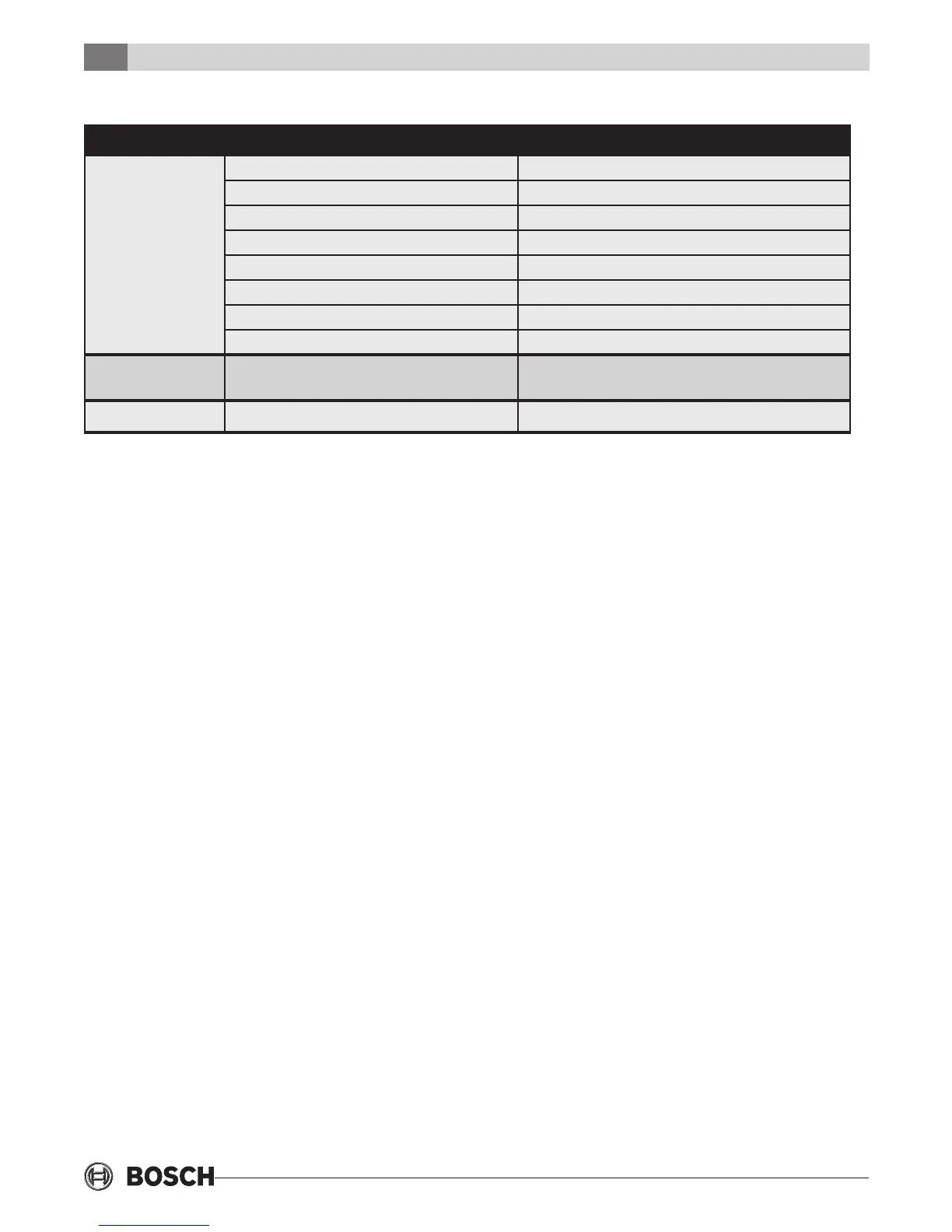

TROUBLESHOOTING

Problem Possible Cause Checks and Corrections

No Flow

Low Flow

No Power Check power supply

On/Off Switch Position Set switch to “ON” position

Compressor Contactor Engage heat pump contactor

Broken or loose wires Repair or tighten wires

Air Lock Purge air from piping system

Stuck pump shaft/impeller Remove pump cartridge and clean

Defective pump Replace pump

Kinked or under sized water piping Repair kink and check for proper line size

High Water

Temperature

Water temp limit closed Stuck limit switch

Sensor not attached securely to line

Low Heat Output

Scaled or fouled heat exchanger Clean heat exchanger

Loading...

Loading...