Pre-Installation

Greenstar Danesmoor Utility

2022+

and Utility System

2022+

- 6 721 846 263 (2022/01)12

4.3 Oil supply

• This appliance is suitable for Kerosene (Class C2) only, no other

fuel must be used.

• Plastic or steel tanks should be installed to BS 5410.

A steel tank should conform to BS 799: part 5 and have a slope of

1:24 away from the outlet with a sludge cock at the lower end.

• Do not use galvanised steel tanks or pipework for the oil system.

• Do not use soldered joints on the oil supply pipework.

4.3.1 Single pipe gravity feed system:

The oil storage tank [1] must be positioned so that the oil level does not

exceed 4 metres above the level of the burner oil pump [9] and in

addition the oil level must be at least 300mm above the oil pump [9].

Where the maximum oil level in the oil storage tank exceeds 4 metres, a

head breaking device must be installed between the tank [1] and the

burner oil pump [9].

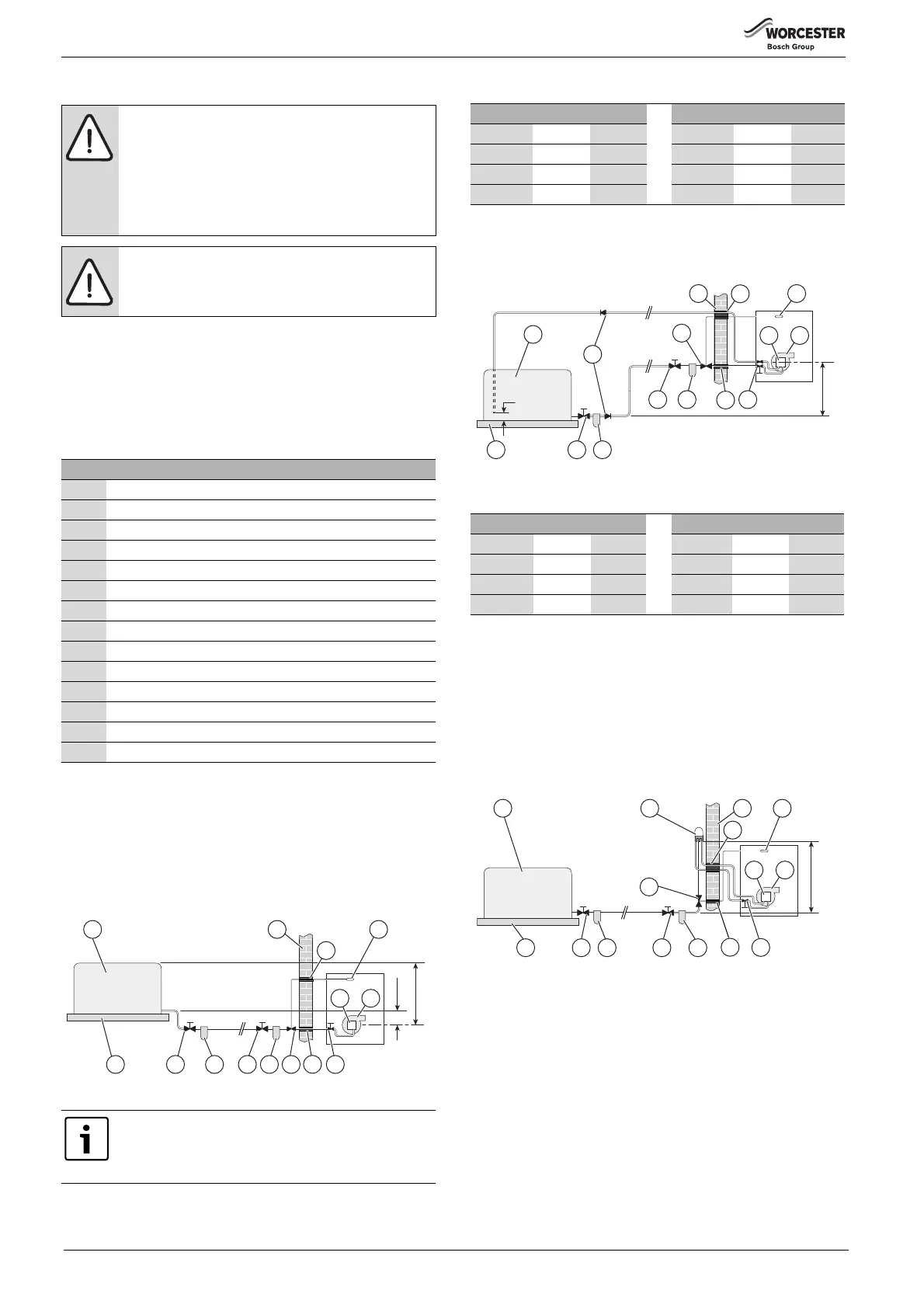

Fig. 5 Single pipe feed

Maximum pipe run for single pipe gravity fed system

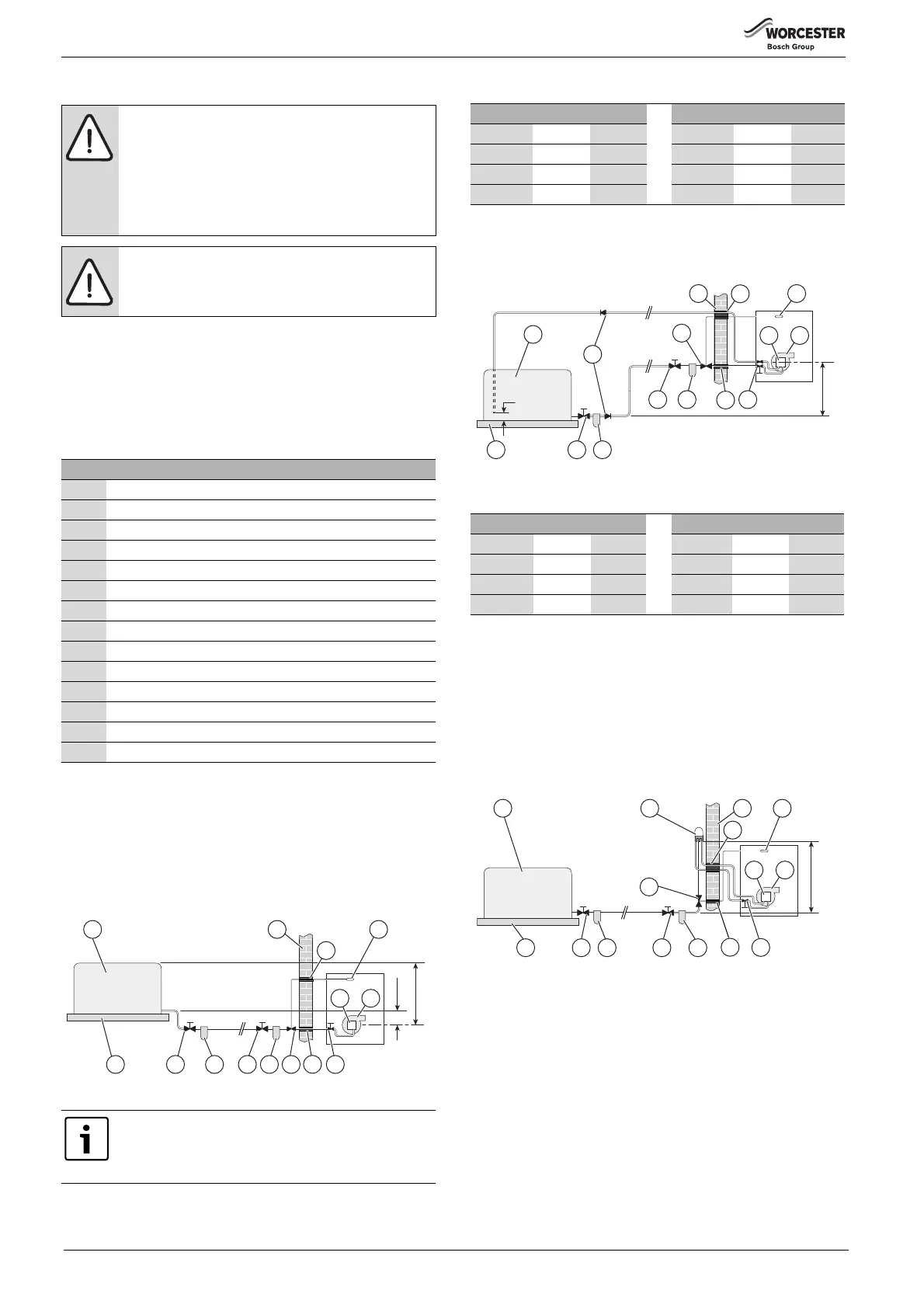

4.3.2 Double pipe sub-gravity feed system:

Maximum suction height 3.5 m. Non-return valves must be fitted to the

inlet and return oil line between the oil pump [9] and oil storage tank [1].

Fig. 6 Double pipe feed

Maximum pipe run for double pipe sub-gravity fed system

4.3.3 Single pipe suction lift with de-aerator:

Maximum suction height 3.5 metres. The oil tank [1] must be positioned

below the oil pump [9]. Create an inlet and return loop between the de-

aerator [12] and oil pump [9].

A non-return valve must be incorporated within the de-aerator or fitted

to the oil line between the oil storage tank [1] and the de-aerator [12].

A top feed oil tank fitted with a de-aerator using an internal non-return

valve should have any non-return valves fitted in the base of the tank to

the suction line removed to assist purging air from the oil line.

Fig. 7 De-aerator feed

Maximum pipe run for single pipe suction lift with de-aerator

NOTICE: Contaminated oil supplies can damage the

appliance.

Failure to ensure that the oil supply is clear of

contaminants may invalidate the appliance warranty.

▶ Ensure the oil supply is free of contaminates and

measures are taken to prevent contamination of the

appliance.

NOTICE: Liquid fuel supply pipes should be provided

with mains equipotential bonding in accordance with BS

7671.

Key to Oil supply illustrations, figures 5, 6 & 7

1 Oil storage tank

2 Full base (plastic tank)

3 Isolating valve

4 Oil strainer and water separator

5 Fire valve to BS 5410

6External wall

7 Oil filter (70μm max filtration size)

8 Fire valve sensor

9Oil pump

10 Oil burner

11 Non-return valve

12 De-aerator

13 Appliance isolation valve

14 Sleeve

Table 4 Key to oil supply feed system

All dimensions are in metres unless otherwise stated.

The maximum pipe run figures are based on using

copper pipe with an inside diameter of 2mm less than

the outside diameter.

6720813284-08.3Wo

1

2

3 4

300mm

Min.

4m Max.

6 8

53

109

13

7

14

14

Head (m) 10mmØ 12mmØ Head (m) 10mmØ 12mmØ

0.5 12 30 2.5 62 100

1.0 25 69 3.0 74 100

1.5 37 91 3.5 87 100

2.0 49 100 4.0 99 100

Head (m) 10mmØ 12mmØ Head (m) 10mmØ 12mmØ

050100 2.0 26 66

0.5 44 100 2.5 20 50

1.0 38 95 3.0 14 37

1.5 32 80 3.5 8 22

3.5m Max.

150mm

6720813284-09.2Wo

1

2

3 4

73

6 8

5

11

109

13

14

14

6720813284-10.2Wo

2

4

3.5m Max.

1 6

12

5

33

7

109

8

13

14

14

Loading...

Loading...