Service and Spares

Greenstar Danesmoor Utility

2022+

and Utility System

2022+

- 6 721 846 263 (2022/01) 51

7.12 Re-commissioning the burner

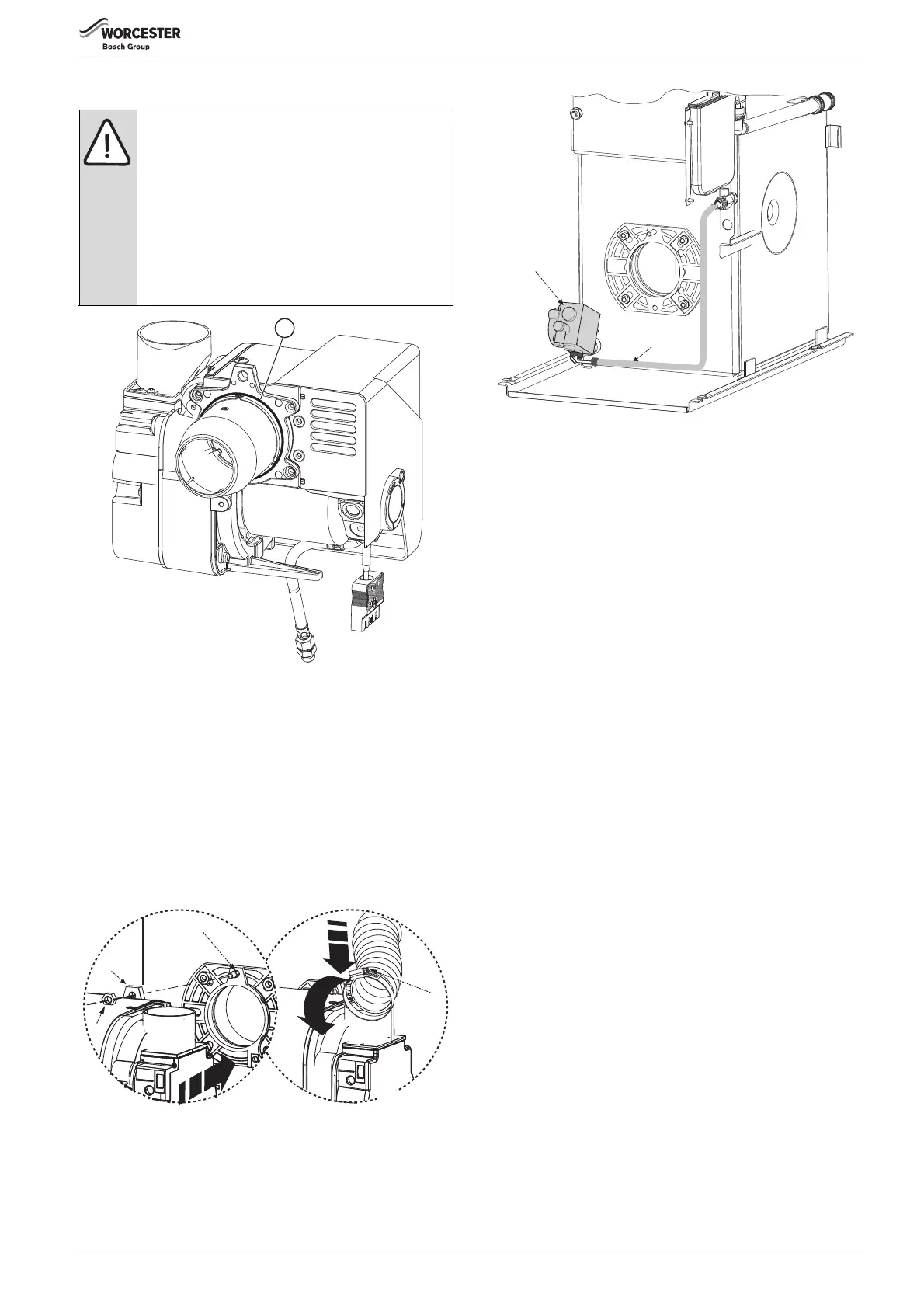

Fig. 88 18/25 and 25/32 Burner O-ring seal shown

1. Align burner combustion head into burner collar.

▶ Locate the burner retainer [A] over the threaded lug on the collar [B],

ensure that the burner is level and push the burner firmly onto the

flange ensuring the O-ring seal is fully engaged. Support the burner in

position and secure with the retaining nut [C]. Tighten sufficiently to

hold the burner but do not over tighten.

▶ Check that the burner is seated correctly on its mounting flange and

that the oil hose/s are routed correctly as shown in Fig. 90 and not

trapped in front of or underneath the burner.

▶ Attach air duct pipe and tighten clip (D) to secure to the burner air

intake.

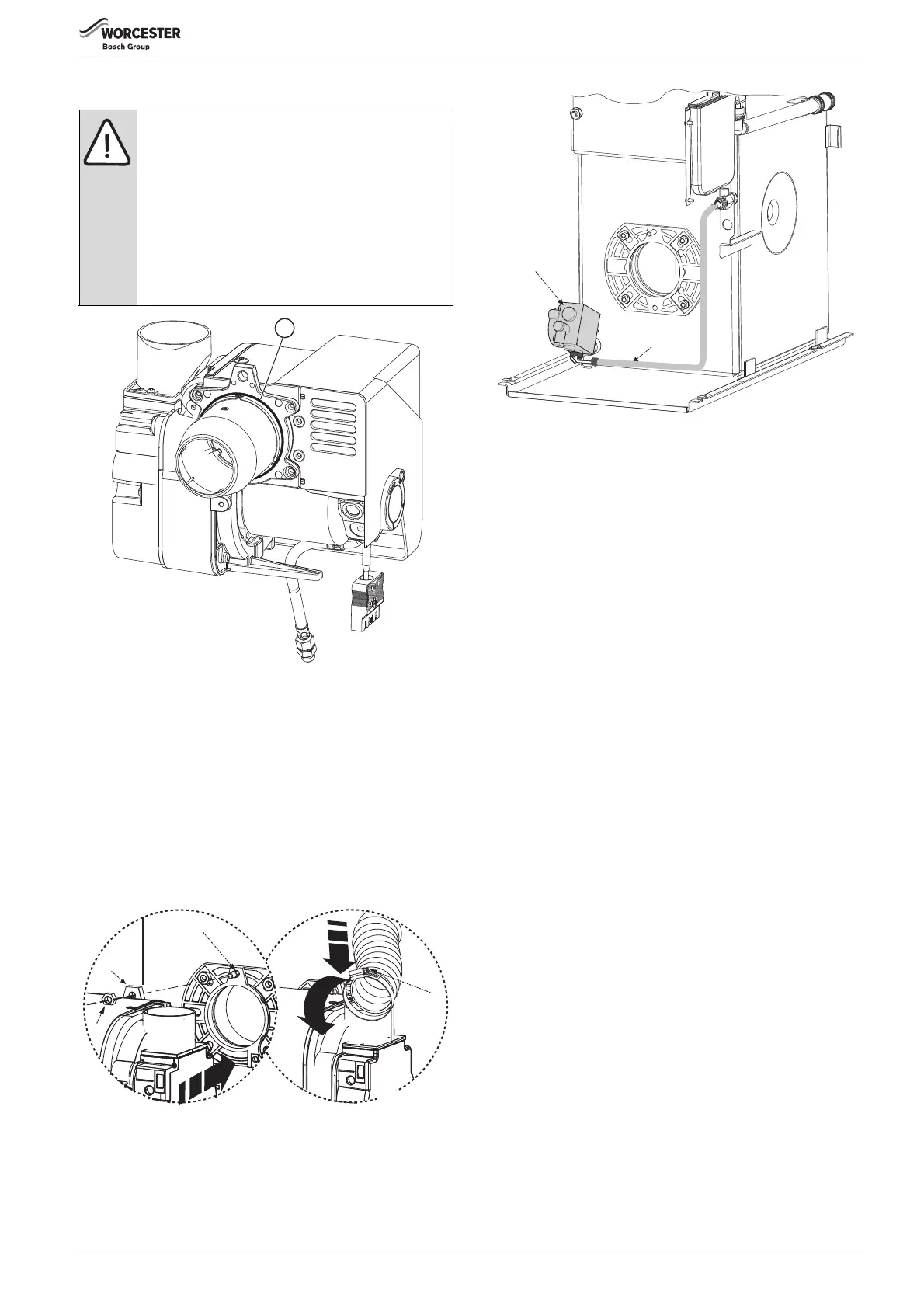

Fig. 89 Refitting the burner

Fig. 90 Oil pump and hose detail

[1] Oil pump

[2] Flexible oil hose route. Ensure that the rigid 90° connection at the

pump points to the right when the boiler is viewed from the front

and the flexible hose follows the route as show in the figure above.

2. Swing control box back up into operating position and retain in place

by replacing the two securing screws (E) in the bottom locations.

▶ Plug burner lead (F) into control box.

▶ Connect an oil pressure gauge to the oil pump, run the burner and

check the oil pressure is correct for the required boiler output. Check

that the smoke reading is between 0 - 1. If above 1 check the air

setting. If the air setting is correct check that the burner has been

reassembled correctly.

Allow the boiler to warm up then check the combustion settings are

correct as indicated in table 10 on page 44, ensure CO

2

levels are

correct. Adjust the air shutter if necessary see page 44, figure 70 for

details.

When the combustion is correct turn off the boiler, remove the

pressure gauge and refit the blanking plug and plastic cover.

3. Locate the front panel by aligning the ball studs with the retaining

slots and secure near the top and at the bottom by gently pushing

home the ball studs into the retaining slots (I). Remember always to

apply pressure at the edges of the panels to avoid damage.

WARNING: Flue gas leakage

The seal between the burner and the mounting flange

must form a gas tight seal to prevent leakage of

potentially dangerous gas from the combustion

chamber.

▶ Unless the burner is level when pushing the burner

into the flange the O-ring may not seat properly

allowing flue gas to escape!

▶ Always check that the O-ring seal (Fig 88item A) is in

good condition before fitting the burner.

Replace the O-ring seal if defective.

6720821683-25.1Wo

A

Loading...

Loading...