Pre Start Inspection and Operation

3.8

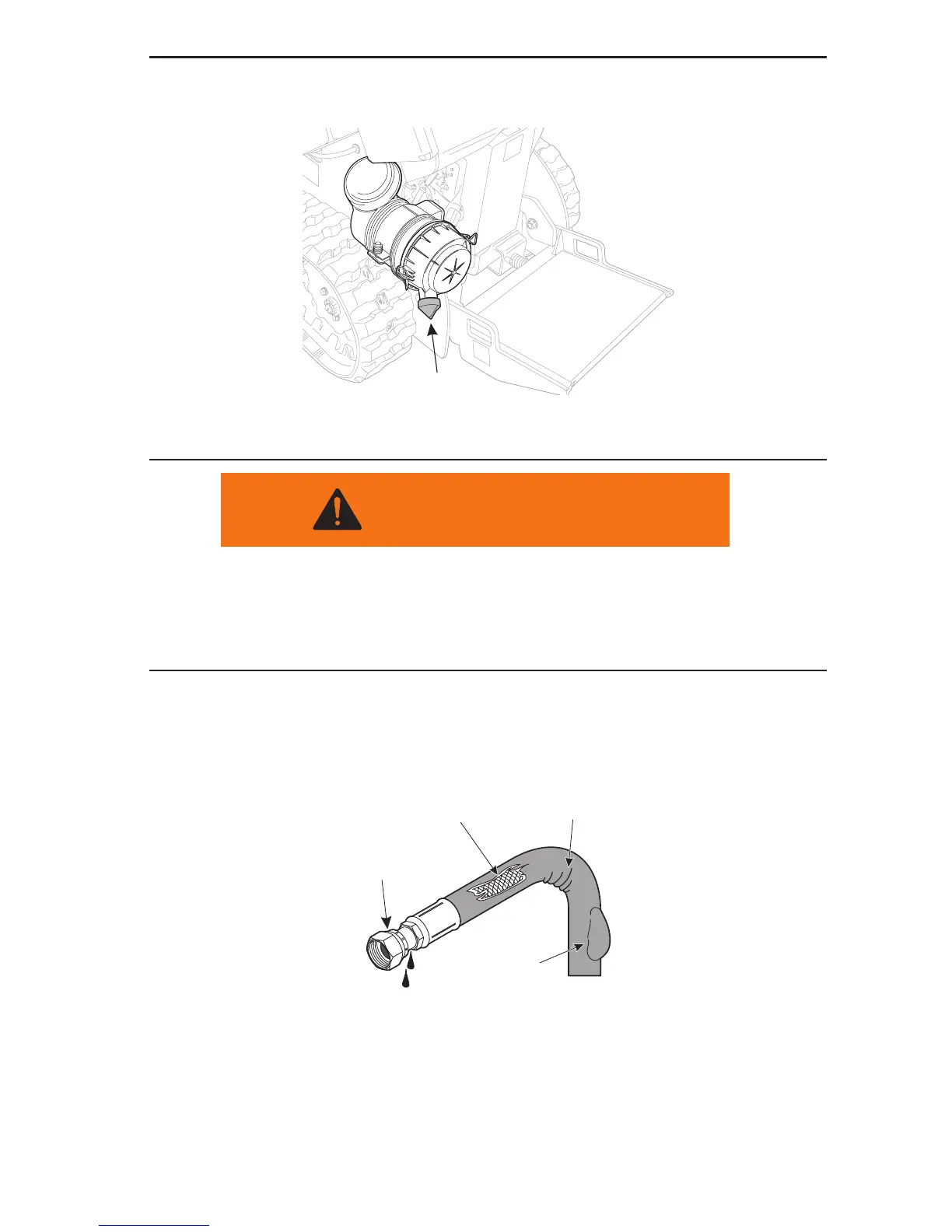

7. Release dirt from separator tube at the bottom of the air lter by squeezing the rubber dust

ejector valve (Item 1, Figure 3–7) underneath the air lter.

Figure 3-7 Release Dirt from Air Cleaner

8. Check all hydraulic hoses, lines and ttings.

Hydraulic oil under pressure can penetrate body tissue causing serious injury and

possible death. When troubleshooting a hydraulic system for leaks, always use

cardboard or wood as a detector. DO NOT USE YOUR BARE HANDS. If you are

injected with hydraulic oil or any other uids, immediately seek treatment by a doctor

trained in the treatment of penetrating uid injuries.

• Visually inspect all of the hydraulic hoses, lines and ttings for signs of damage, wear

or leaking.

• If any signs of damage are visible, do not operate the machine until repairs have been

made.

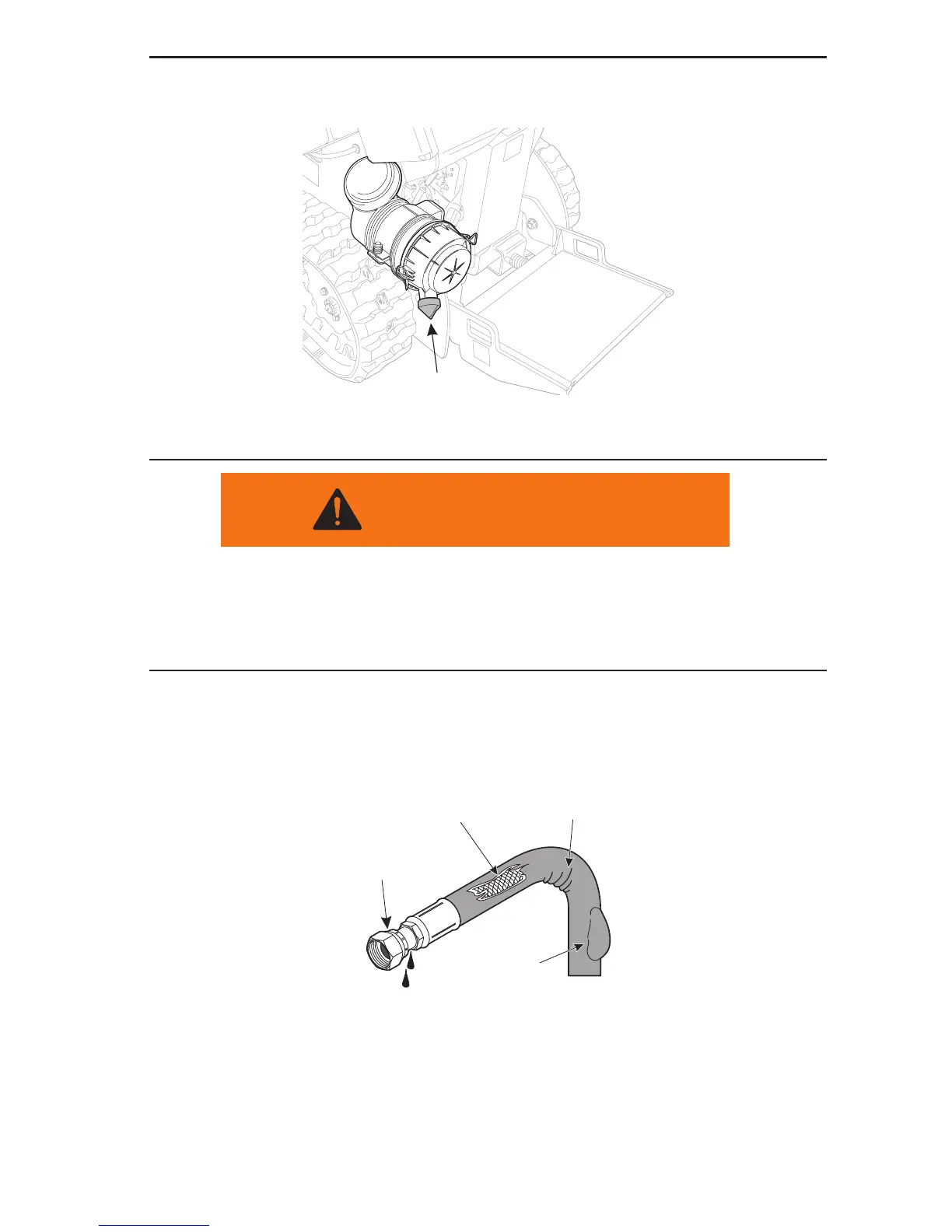

• Some examples of common hydraulic hose damage are shown in Figure 3–8.

Figure 3-8 Hydraulic Hose Damage

1

3

4

2

WARNING

1. End ttings damaged or leaking

2. Outer covering chafed or cut, and wire reinforcing is exposed

3. Hose shows signs of kinking or crushing

4. Outer covering ballooning

Loading...

Loading...