9

Series 70 Electric Actuator

Operation and Maintenance Manual

Heater

To prevent condensation from forming inside the

actuator, Bray offers an optional heater. The heater is

a PTC (Positive Temperature Coefficient) style which

has a unique temperature - resistance characteristic.

The heater self-regulates by increasing its electrical

resistance relative to its temperature. The heater does

not require external thermostats or switches to control

its heat output. It is constructed of a polycrystalline

ceramic, sandwiched between two conductors, and

wrapped inside a thermally conductive electrical

insulator.

Connect the heater wires to the terminal strip as

indicated on the wiring diagram.

NOTE: The heater must have a constant power supply

to be effective.

WARNING

The heater surface can reach temperatures in excess

of 200 degrees Celsius

Heater Kit Consists of:

1. Heater with flying leads

2. Heater Mounting Bracket

3. #10 pan head screw, Phillips drive

Tools required:

• For terminal wiring: Screwdriver, 3/16” tip flat blade

• For heater mounting screw: Screwdriver, No.1 Phillips

Installation Procedure

The heater is mounted through a hole provided in

the switchplate.

Before servicing unit, switch all power off at the service

panel and lock the service disconnecting means to

prevent power from being switched on accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

Disconnect all power to the unit.

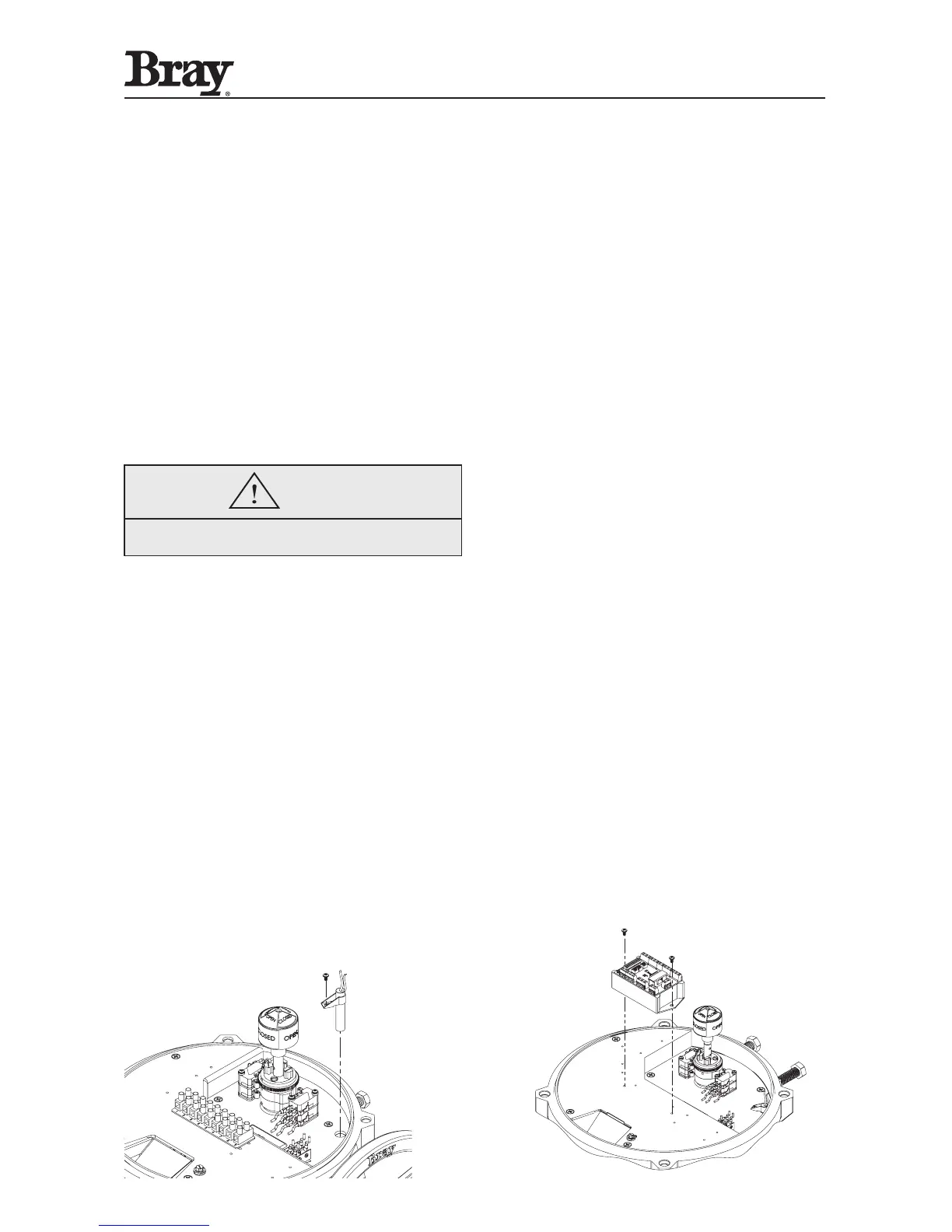

1. Place the heater snugly into its mounting bracket

until approx. 1/2 to 1” is left above the bracket as

shown in diagram.

2. Slip the heater into its mounting hole.

3. Align the fastening hole in the bracket with the

threaded screw hole in the plate. Fasten the heater

to the switchplate.

4. Connect the heater wires to the terminal strip as

indicated on the wiring diagram.

Servo-Pro Module

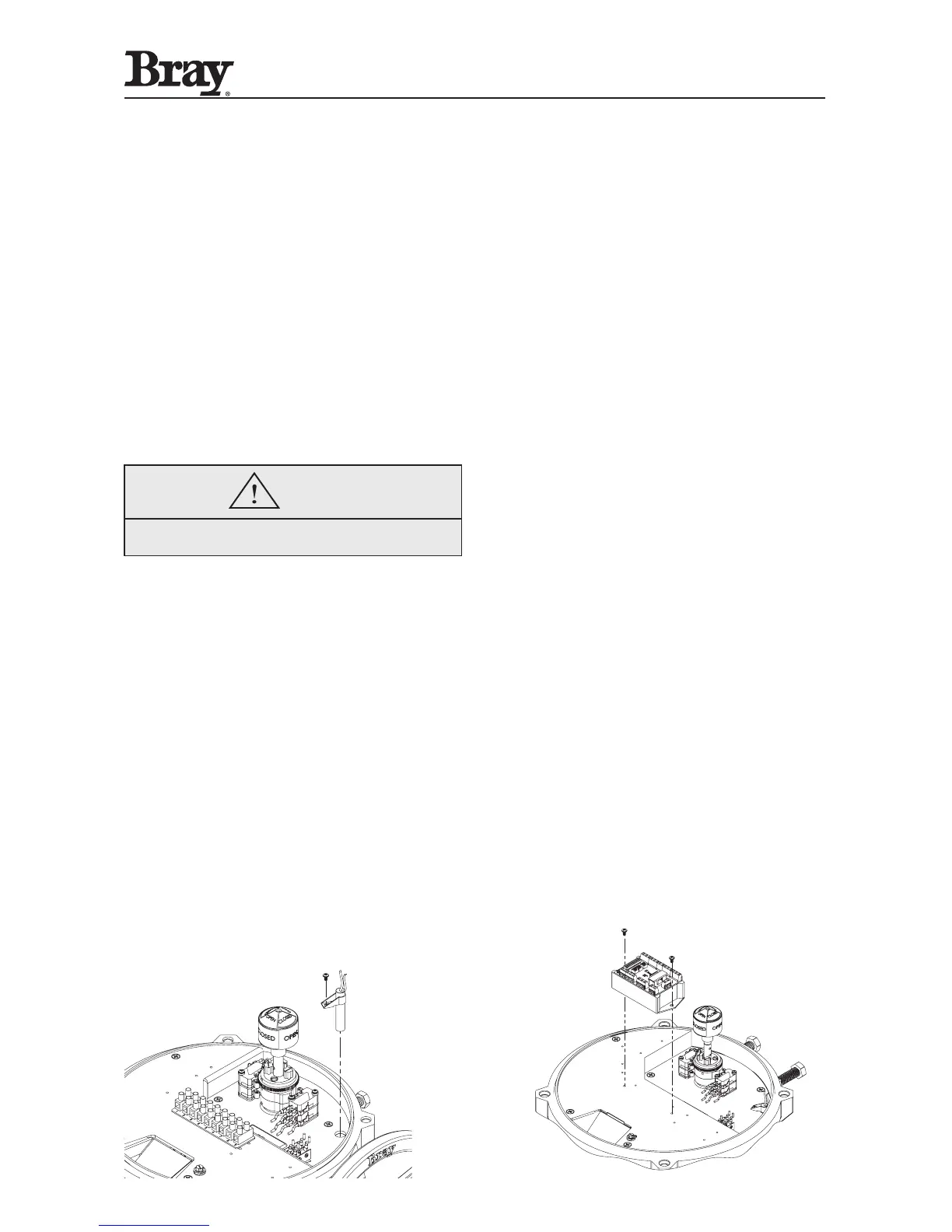

Servo kits can be field installed on any continuous

duty actuator (30, 60, or 110 sec. operation speed) to

provide proportional positioning in response to a control

signal. Intermittent duty actuators are not adaptable

for servo control.

Servo Kit Consists of:

1. One servo module

2. Four #6 cross drive pan head screw (two for servo,

two for feedback potentiometer)

3. One potentiometer assembly

4. Two #6 type A internal lockwashers (for pot)

5. One wiring diagram sticker for attaching to inside

of actuator’s cover

6. One wiring diagram sticker for servo units with

torque switches

Tools required:

• For actuator terminals wiring Screwdriver, 3/16”

flatblade

• For servo terminals: Screwdriver, No.1 Phillips

• For servo and pot mounting screws: Screwdriver, No.2

Phillips

Loading...

Loading...