10

Series 70 Electric Actuator

Operation and Maintenance Manual

Installation Procedure

• Disconnect all power to the unit.

• Remove the on/off duty, 9 point terminal strip and

its marker.

1. Disconnect all wiring to the terminal strip.

2. All wiring in the actuator is color coded to facilitate

wiring, and does not need to be tagged or marked.

3. Field wiring should be marked if it is not already

color coded.

Mount the servo module

4. Secure the servo card module onto switchplate with

the 2X #6 screws.

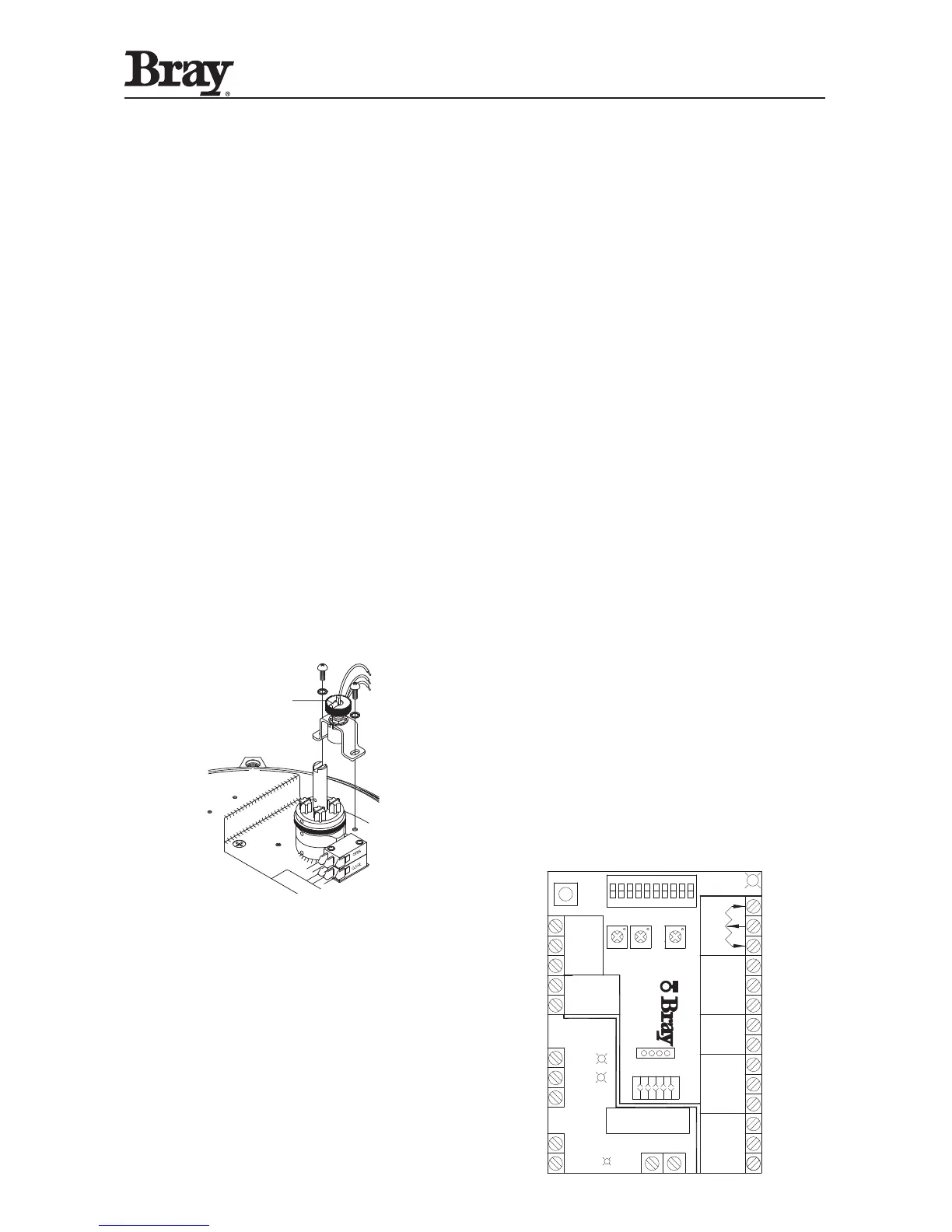

Install the potentiometer assembly

5. The potentiometer installs next to the camshaft

where there are two threaded holes provided.

6. The potentiometer assembly must be mounted in

the correct orientation, with the actuator in its fully

open (counter clockwise) position, the indicator shaft

should be in-line with raised green rib on pot gear.

7. Push the assembly towards the cam to mesh the pot

gears. Then tighten the mounting screws.

Note: On Housing Size 180, the raised green rib on

pot gear should be aligned with arrow on lower gear

box’s position indicator plate.

8.

Rotate the actuator handwheel so that the red cam

lobe is facing the body of the potentiometer. Make

sure that the cam is not touching the potentiometer

assembly. Readjust the assembly position if necessary.

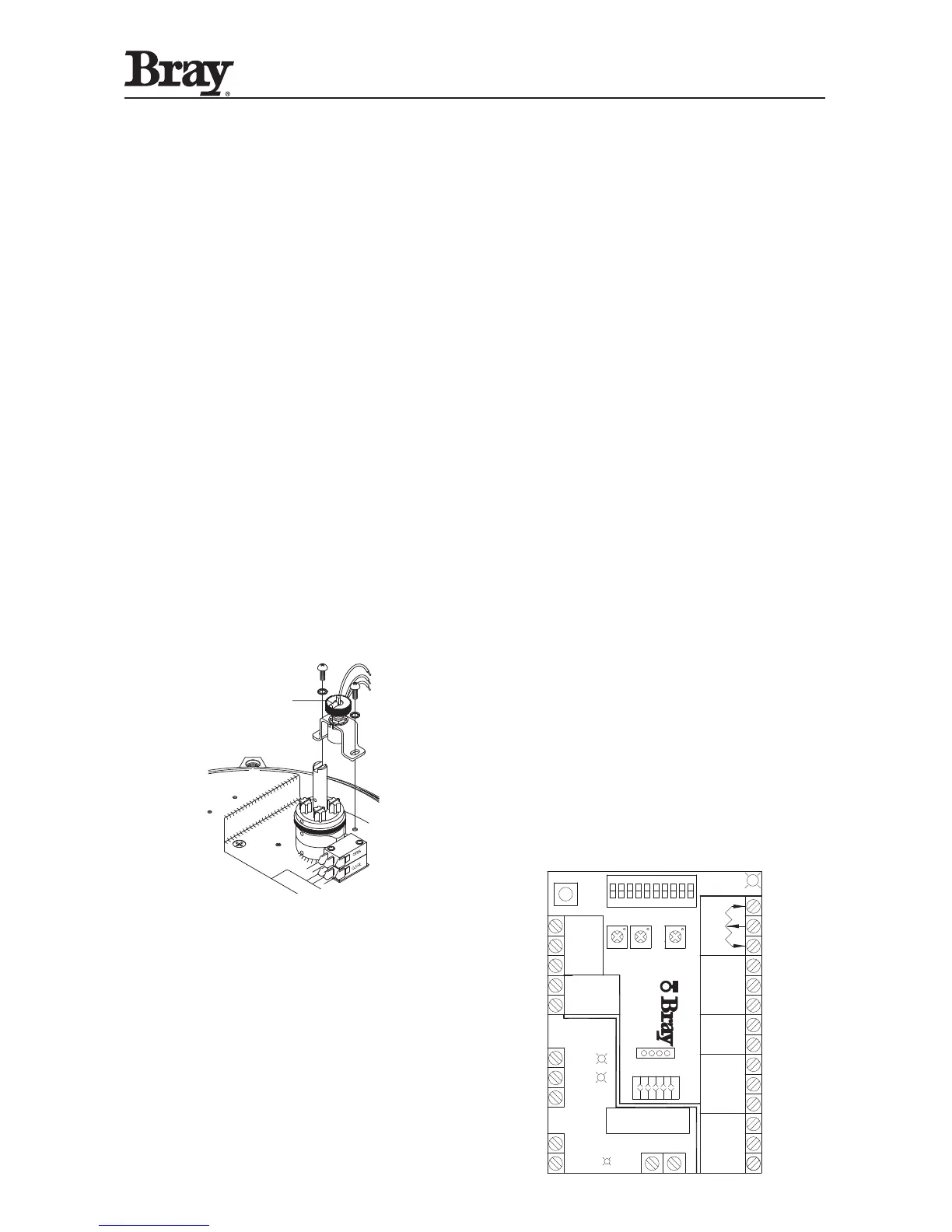

Wire the potentiometer to the servo

9. Connect the potentiometer wires into the terminal

strip on the servo module.

10. Wire according to the wiring diagram provided.

Wire the servo to the actuator

11. Wire according to the wiring diagram provided.

12. See the servo calibration instructions.

Servo Calibration

The calibration procedure defines the limits of operation

of the Series 70 Actuator between the fully open valve

position and the fully closed valve position. The cams

on the Series 70 Actuator define the fully open and

closed positions of the valve and may be set at any

degree of opening. The only requirement is that the

open cam limit setting must set at a higher degree of

opening than the closed cam limit setting. In other

words, the “Open” position must be more open than

the “Closed” position.

Calibration is performed as follows:

1. Adjust the Open and Closed limit switch cams on

the Series 70 Actuator to the desired position.

2. Engage the handwheel and move the Series 70

Actuator to its mid position.

NOTE: An analog signal source is not required

for calibration. Press and hold the “Calibrate” Set

pushbutton for a minimum of 2 seconds. When the

servo status LED begins to flag rapidly, release the

button. The servo will now seek both travel limits and

record these values to its nonvolatile memory. Following

a successful calibration, the status LED will begin to

flash a slow single green flash. If the calibration is

unsuccessful, the status LED will alternately flash red

and green. If this occurs, make sure the cams and the

potentiometer are set correctly.

This completes the “Self Calibration” procedure.

After completing the calibration procedure, it is

good practice to apply the fully closed and fully open

Command Signals, and verify that the S70 Actuator

moves to the proper positions.

* Refer to Servo Pro Version 3.0 Operation and

Maintenance Manual for more details

MOTOR

OPEN

1

ON

MOTOR

CLOSE

FUSE

NEUTRAL

NEUTRAL

LINE

Loading...

Loading...