Do you have a question about the Briggs & Stratton E Series and is the answer not in the manual?

Instructions for flywheel removal and installation using specific tools.

Details on float bowl installation, screw threading, and needle valve seat removal.

Specifies reduced oil capacity (15 oz) and symptoms of overfilling.

Procedure for transferring the barcode label to a new blower housing.

Instructions for piston orientation, pin clip, connecting rod, and piston ring installation.

Procedure for installing sump bolts and the self-tapping sump screw in sequence.

Procedure for installing the carburetor spacer and mounting bracket on the cylinder head.

Procedure for adjusting the governor linkage and shaft while holding the nut.

Procedure for adjusting top no-load speed using a tang bender, with speed chart.

Table listing various engine parameters like bore, stroke, displacement, and oil capacity.

Torque values for fasteners in pound-inches and pound-feet.

Torque values for fasteners in Newton-meters.

Standard and reject dimensions for cylinder bore, head valve guides, and seats.

Standard and reject dimensions for crankshaft journals, cam shaft journals, and connecting rod.

Standard and reject dimensions for piston pin diameter, bore, and piston ring end gap/clearance.

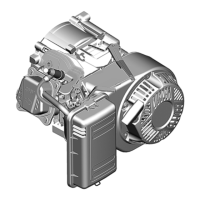

| Brand | Briggs & Stratton |

|---|---|

| Model | E Series |

| Category | Engine |

| Language | English |

Loading...

Loading...