Do you have a question about the Bruker NMR CASE and is the answer not in the manual?

Check sample lift airflow speed and pressure for proper sample ejection. Adjustments may be needed.

Sample holder tray slams when advancing, possibly due to excessive sample lift air.

Light barrier slows sample lift. Use control modifier cable to disengage.

Four seals are crucial to prevent sample lift air leaks. Ensure proper installation.

Verify the adapter collar is correctly seated on the BST shim stack.

Proper alignment of the adapter collar, seal ring, and interface tube is critical.

Check the pneumatic cylinder for correct closing of the air bypass exit hole.

Ensure correct seating and alignment of the interface tube within the adapter collar.

Ensure the NMR Case is horizontal and the shim stack is vertical.

Check BST shim stack for sharp edges on sample insertion points; file or replace if found.

Verify correct opening and closing of the sample lift air bypass for proper insertion.

Excessive sample lift airflow can cause slow insertion. Reduce airflow as needed.

Adjust flow reducers to ensure the sample holder tray advances and stops firmly.

Check alignment as described in section 1.6.

Check interface tube as described in section 1.8.

Reset sample tracking memory after manual sample removal or use of manual mode.

Increase pneumatic piston airflow by adjusting flow reducers #1, 2, 3, 4.

Observe motion controller LED sequences for diagnostic purposes.

Verify I-0 is ON when the sample is on the tray for proper rotation.

Ensure I-3 is ON before I-0 for correct sample lift airflow during ejection.

Ensure the controller is at least 2 meters away from the magnet dewar cryostat.

Procedure to open the motion controller cover for inspection and access.

Observe initial LED status on motion controller startup for diagnostics.

Check LED status two seconds after motion controller power-on.

Check LED status four seconds after motion controller power-on.

Press the RESET switch if O-3 LED is green to reset sample insertion memory.

Check power cord and fuse if no lights are observed on the controller.

Replace motion controller if initial LEDs are missing or a red light persists.

Test sensor inputs by blowing into them and checking corresponding LEDs.

Observe outputs CYL A and CYL B behavior during controller switching.

Unplug and replug the spin rate cable connector at the BST shim stack.

Remove the BSMS sample control modifier cable B1428 for testing.

Check the sample spin rate settings for proper configuration.

Ensure the NMR Case and magnet are properly leveled for reliable operation.

Adjust sample lift airflow as per sections 1.1 and 2.4.

Adjust sample holder tray movement as per sections 2.5 or 5.

Check seating of collar and adapter tube as per section 1.8.

Check sample lift air bypass closing as per section 1.7.

Check collar and adapter tube seating as per section 1.8.

Check sample lift airflow as per section 1.1.

Check alignment of collar, ring, and brown tube as per section 1.6.

Check sample lift airflow as per section 1.1.

Check sample lift air bypass closing as per section 1.7.

Troubleshoot motion controller power issues as per section 4.

Troubleshoot motion controller air pressure issues as per section 4.

Ensure sample holder tray advances firmly as per section 2.5.

Check sample lift air bypass opening as per section 2.3.

Reduce excessive sample lift airflow as per section 2.4.

Ensure sample holder tray advances firmly as per section 2.5.

Check alignment of collar and white ring as per section 1.6.

Check seating of collar and adapter tube as per section 1.8.

Check BST shim for sharp edges as per section 2.2.

Ensure NMR Case or magnet is leveled as per section 1.8.

Troubleshoot motion controller power issues as per section 4.

Check for blown fuse as per section 4.

Troubleshoot motion controller air pressure issues as per section 4.

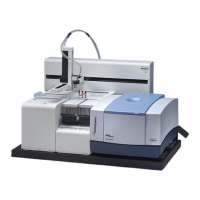

| Brand | Bruker |

|---|---|

| Model | NMR CASE |

| Category | Laboratory Equipment |

| Language | English |