86

A11392

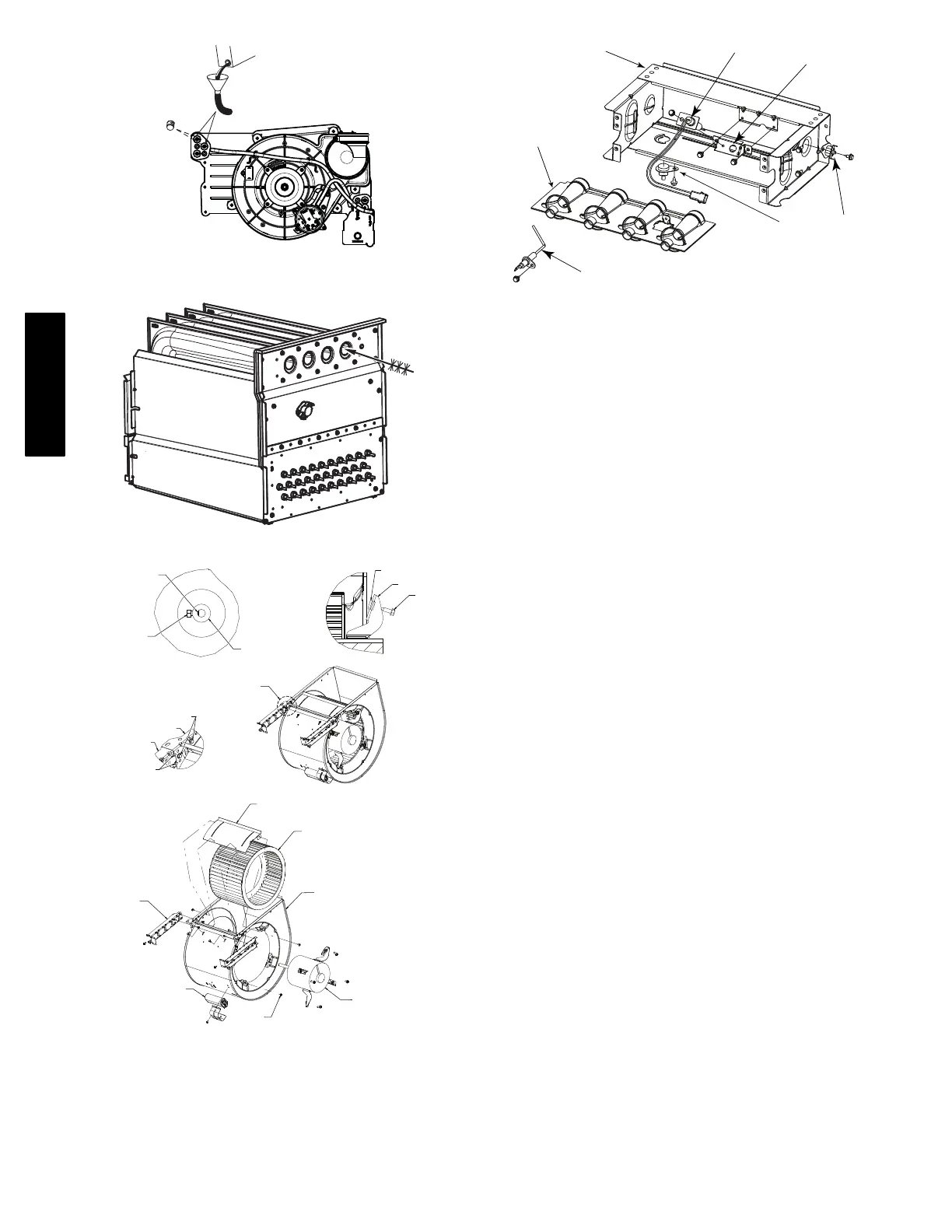

Fig. 68 − Priming Condensate Trap

A11273

Fig. 69 − Cleaning Heat Exchanger Cell

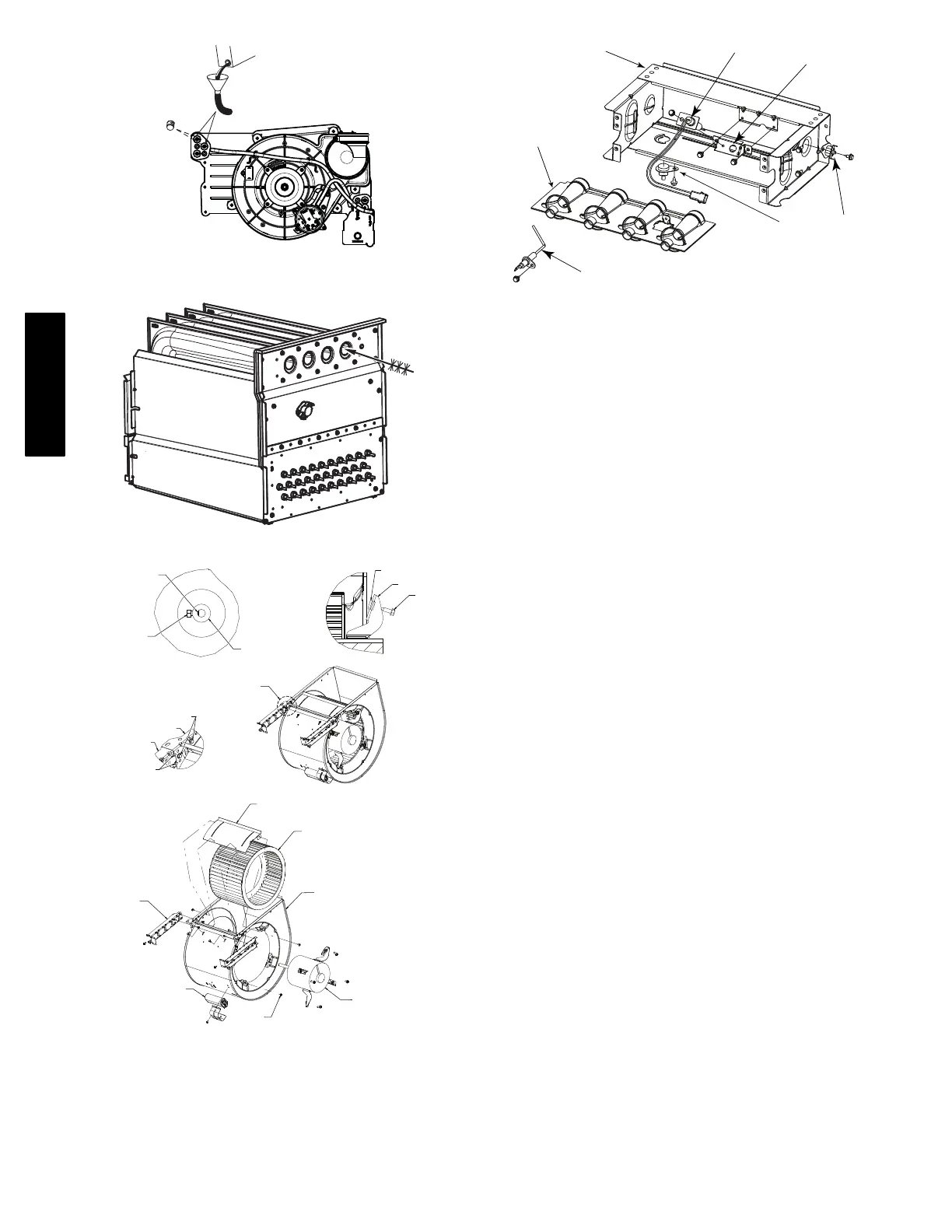

SET SCREW

MOTOR WHEEL HUB

MOTOR SHAFT FLAT

SCREW

MOTOR ARM

GROMMET

SCREW LOCATION

BLOWER HSG ASSY

BRACKET

BRACKET

ENGAGEMENT

SEE DETAIL

A

CAPACITOR

OR POWER CHOKE

(WHEN USED)

BRACKET

SCREW

(GND)

BLOWER HSG ASSY

MOTOR, BLOWER

WHEEL, BLOWER

CUTOFF, BLOWER

DETAIL

A

A11584

Fig. 70 − Blower Assembly

FLAME SENSOR

(BELOW BURNER)

FLAME ROLLOUT

SWITCH

BRACKET, IGNITER

IGNITER

BURNER SUPT. ASSY

BURNER ASSY

A11403

Fig. 71 − Burner Assembly

SEQUENCE OF OPERATION

NOTE: Furnace control must be grounded for proper operation or

else control will lock out. Control is grounded through

green/yellow wire routed to gas valve and burner box screw. Using

the schematic diagram in Fig. 73, follow the sequence of operation

through the different modes. Read and follow the wiring diagram

very carefully.

NOTE: If a power interruption occurs during a call for heat

(W/W1 or W/W1−and−W2), the control will start a 90−sec

blower−only ON period two sec after power is restored, if the

thermostat is still calling for gas heating. The amber LED light will

flash code 12 during the 90−sec period, after which the LED will

be ON continuous, as long as no faults are detected. After the

90−sec period, the furnace will respond to the thermostat normally.

The blower door must be installed for power to be conducted

through the blower door interlock switch ILK to the furnace

control CPU, transformer TRAN, inducer motor IDM, blower

motor BLWM, hot−surface igniter HSI, and gas valve GV.

1. Two−Stage Heating (Adaptive Mode) with Single−Stage

Thermostat

See Fig. 38 and 39 for thermostat connections

NOTE: The low−heat only switch SW1−2 selects either the

low−heat only operation mode when ON, (see item 2. below) or

the adaptive heating mode when OFF in response to a call for heat.

See Fig. 64. When the W2 thermostat terminal is energized it will

always cause high−heat operation when the R−to−W circuit is

closed, regardless of the setting of the low−heat only switch. This

furnace can operate as a two−stage furnace with a single−stage

thermostat because the furnace control CPU includes a

programmed adaptive sequence of controlled operation, which

selects low−heat or high−heat operation. This selection is based

upon the stored history of the length of previous gas−heating

periods of the single−stage thermostat.

The furnace will start up in either low− or high−heat. If the furnace

starts up in low−heat, the control CPU determines the low−heat

on−time (from 0 to 16 minutes) which is permitted before

switching to high−heat.

If the power is interrupted, the stored history is erased and the

control CPU will select low−heat for up to 16 minutes and then

switch to high−heat, as long as the thermostat continues to call for

heat. Subsequent selection is based on stored history of the

thermostat cycle times.

The wall thermostat “calls for heat”, closing the R−to−W circuit.

The furnace control performs a self−check, verifies the low−heat

and high−heat pressure switch contacts LPS and HPS are open, and

starts the inducer motor IDM in high−speed.

a. Inducer Prepurge Period

986TB

Loading...

Loading...