PROCEDURE 6—GAS SUPPLY PIPING

The gas pipe to your boiler must be the correct size for the length of run and for the total BTU per hour input of all gas utilization equipment

connected to it. See Table 7 for the proper size. Be sure your gas line complies with local codes and gas company requirements.

The boiler and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at

test pressures in excess of 1/2 psig (3.5kPa).

The boiler must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the

gas supply piping system at test pressures equal to or less than 1/2 psig (3.5kPa).

The MAXIMUM GAS SUPPLY PRESSURE for NATURAL gas is 11.0-in.w.c. The MINIMUM GAS SUPPLY PRESSURE for NATURAL

gas is 5.0-in. w.c. (See Table 8.)

The MAXIMUM GAS SUPPLY PRESSURE for PROPANE is 14.0-in.w.c. The MINIMUM GAS SUPPLY PRESSURE for PROPANE is

10.0-in.w.c. (See Table 8.)

NOTE: Gas pressures at or below the minimum gas supply pressures may result in nusiance ignition lock-outs or poor operational performance.

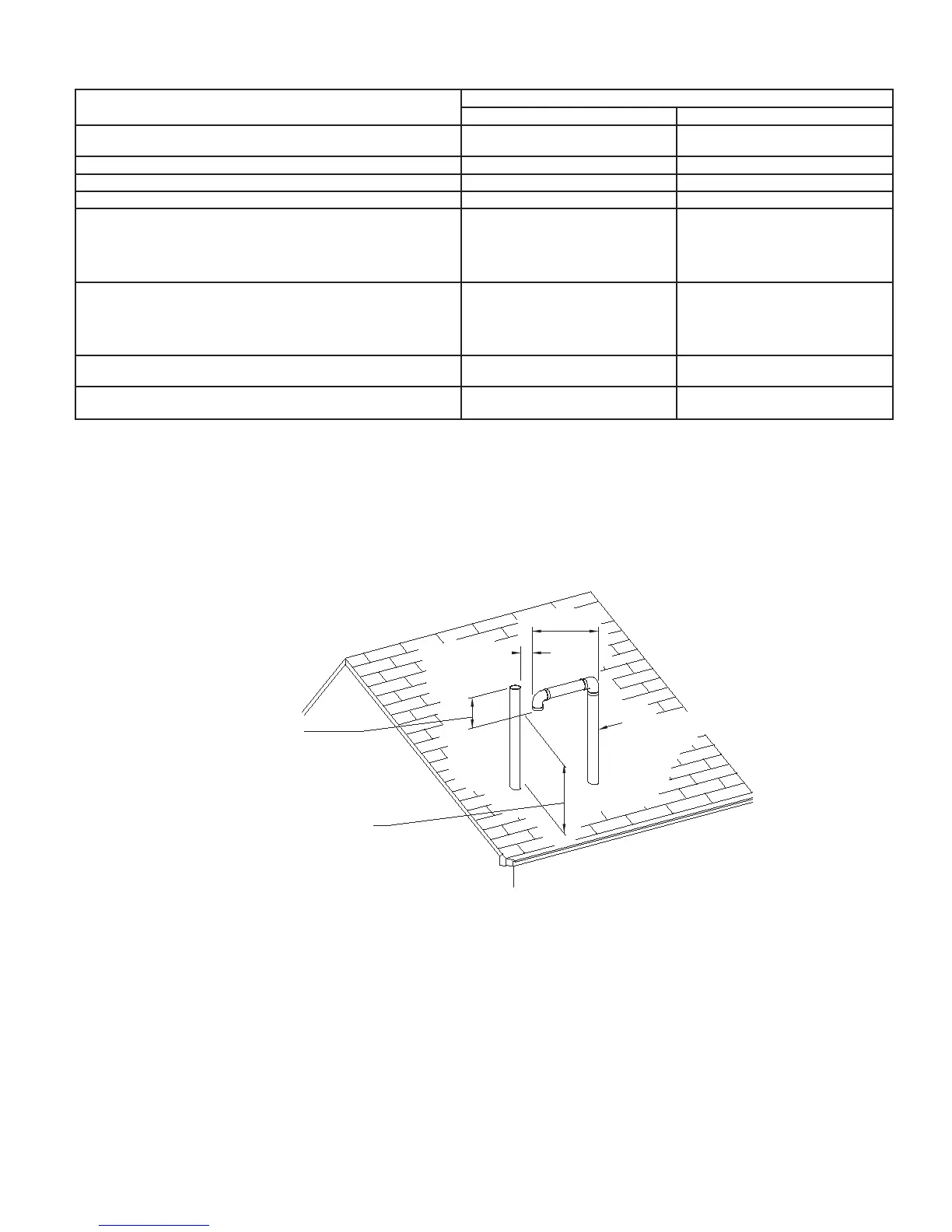

Table 6—Combustion-Air and Vent Pipe

Termination Clearances

LOCATION

CLEARANCE (FT)

U.S.A. Canada

Above grade level or above anticipated

snow depth

11†

Dryer/Water heater vent See Note 5 See Note 5

From plumbing vent stack 33

From any mechanical fresh air intake See Note 4 See Note 6

For furnaces with an input capacity

100,000 Btuh or less—from any non-

mechanical air supply (windows or doors

which can be opened) or combustion-air

opening

11

For furnaces with an input capacity

greater than 100,000 Btuh–from any non-

mechanical air supply (windows or doors

which can be opened) or combustion-air

opening

13

From service regulator vent, electric and

gas meters, and relief equipment

See Note 6 See Note 6

Above grade when adjacent to public

walkway

See Note 3 See Note 3

† 18 in. above roof surface in Canada.

NOTES: 1. If installing 2 adjacent Furnaces, refer to Multiventing and Vent

Terminations section for proper vent configurations.

2. When locating combustion-air and vent terminations, consideration must be

given to prevailing winds, location, and other conditions which may cause

recirculation of the appliance’s own flue products or the flue products of

adjacent vents. Recirculation can cause poor combustion, inlet condensate

problems, and accelerated corrosion of heat exchangers.

3. Vent termination can not terminate less than 2 ft horizontal and 7 ft above

public walkway or where condensate vapor or droplets may be a hazard.

4. Vent termination must be at least 3 feet above any forced draft inlets within 10 feet horizontal. Vent termination must be at least 3 feet horizontal from other direct vent

appliances intake unless otherwise specified by manufacturer.

5. 3 ft radius of furnace air-intake terminal and 1 ft horizontally from vertical centerline of furnace air-intake terminal.

6. Above a meter/regulator within 3 feet horizontally of vertical centerline of meter/regulator vent outlet to a maximum vertical distance of 15 ft.

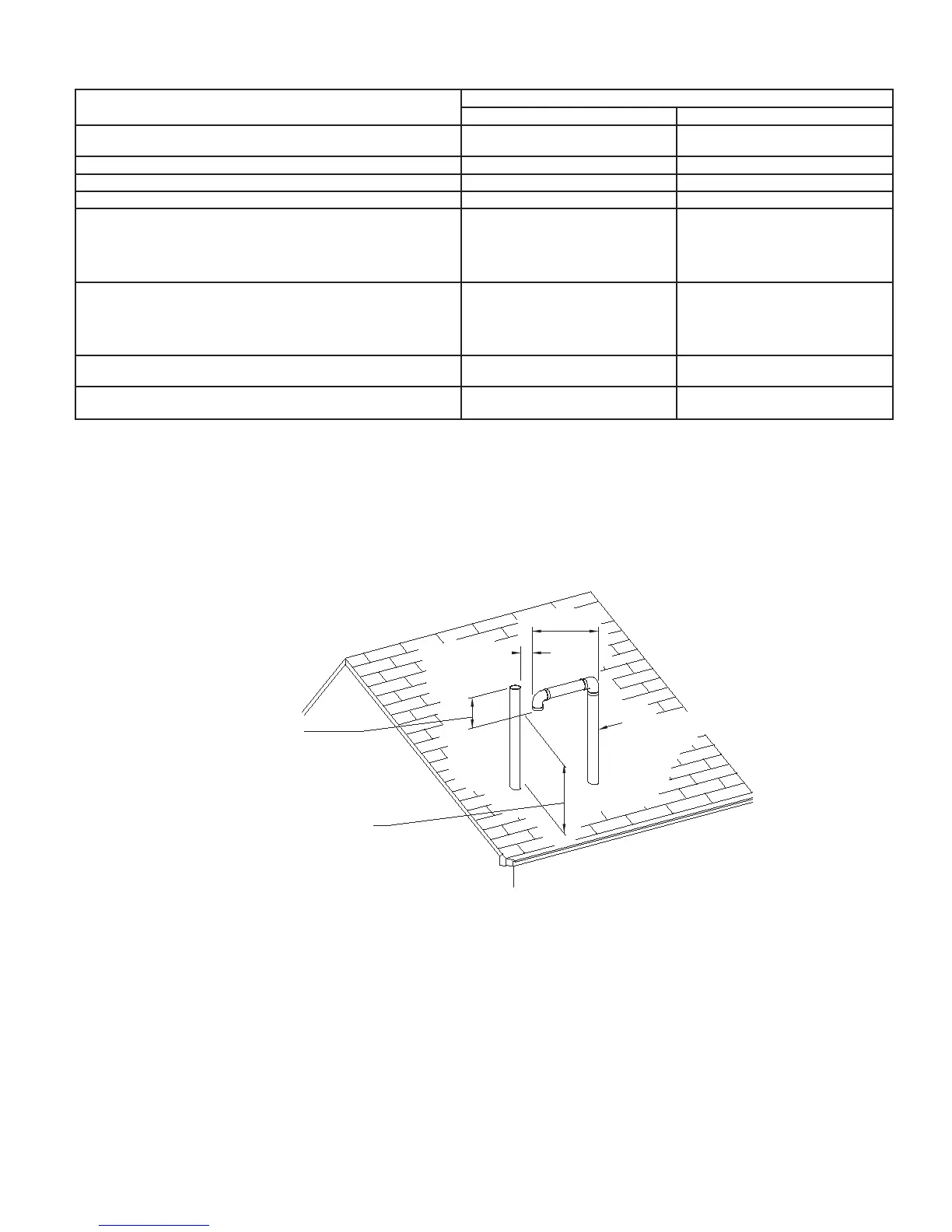

Fig. 12—Roof Vent/Intake Terminations

A99164

12” MINIMUM

VERTICAL SEPARATION

BETWEEN COMBUSTION

AIR INTAKE AND VENT

MAINTAIN 12” MINIMUM

CLEARANCE ABOVE HIGHEST

ANTICIPATED SNOW LEVEL

COMBUSTION

AIR

15” MAXIMUM

3” MAXIMUM

SEPARATION

—15—

→

→

→

Loading...

Loading...