B. Install Your Thermostat

The thermostat location has an important effect on the operation of your boiler system. BE SURE TO FOLLOW THE INSTRUCTIONS

INCLUDED WITH YOUR THERMOSTAT.

Locate the thermostat about 5 ft above the floor on an inside wall. It may be mounted directly on the wall or on a vertical mounted outlet box.

It should be sensing average room temperature. Avoid the following:

DEAD SPOTS: behind doors corners and alcoves.

HOT SPOTS: concealed pipes, fireplaces, TV sets, radios, lamps, direct sunlight, and kitchens.

COLD SPOTS: concealed pipes or ducts, unheated rooms on other side of wall, and stairwells - drafts.

Set heat anticipator at 0.7 amps. Connect 24 volt thermostat leads to the 2 yellow wires located in service switch junction box, located on outer

jacket of boiler. See Fig. 17 for service switch junction box and thermostat field wiring connections.

C. Connect Circulator Pump Wiring

See Fig. 17 for service switch junction box and circulator pump field wiring connections.A5ftwiring harness with flexible metal conduit is

supplied to connect the circulator pump to the service switch junction box. If the two 120 volt circulator wire terminals inside the junction box

are not used, please leave the 2 wire nuts installed on black and white leads to prevent the short circuit.

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

PROCEDURE 8—CONTROLS AND ACCESSORIES

This section provides a brief description of the key controls and accessories found in the BW9 boiler.

See the Troubleshooting section of the Service Hints chapter of this installation manual for detailed sequences of operation and troubleshooting

procedures. See the Repair Parts chapter of this manual for locations of all control components and accessories described.

A. Intergrated Boiler Control (IBC)

The Integrated Boiler Control (IBC) is a microprocessor based controller for a high efficiency gas boiler that monitors all safety controls and which

controls the operation of the combustion air blower, circulator pump, burner, and a combination hot surface igniter/flame sensor. This controller

is not intended for use with a vent damper. This controller is mounted on the control panel inside of the boiler and contains 5 diagnostic indicator

lights.

B. Gas Control Valve

The electrically controlled 24 Volt Honeywell Model VR8205 Combination Gas Control Valve is designed to meet the requirements for use with

hot surface ignition systems found in the BW9. The valve is piped to the gas/air mixer.

C. Hot Surface Igniter

The 120 volt Hot Surface Igniter heats up to 1800°F to initiate combustion of the gas in the BW9 burner. The igniter is mounted next to the burner

through the gas/air mixer. The igniter also serves as a means for proving the main burner flame by flame rectification. In the event of a lack of

flame signal on 3 consecutive trials for ignition, the IBC will lockout. The ″VALVE″ diagnostic indicator lamp (lamp ″D″ on the IBC, See Fig.

21) will blink indicating the failure mode as a lack of flame signal. The IBC is manually reset from lockout by either removing and reestablishing

the thermostat’s call for heat, or by turning the service switch off, then back on.

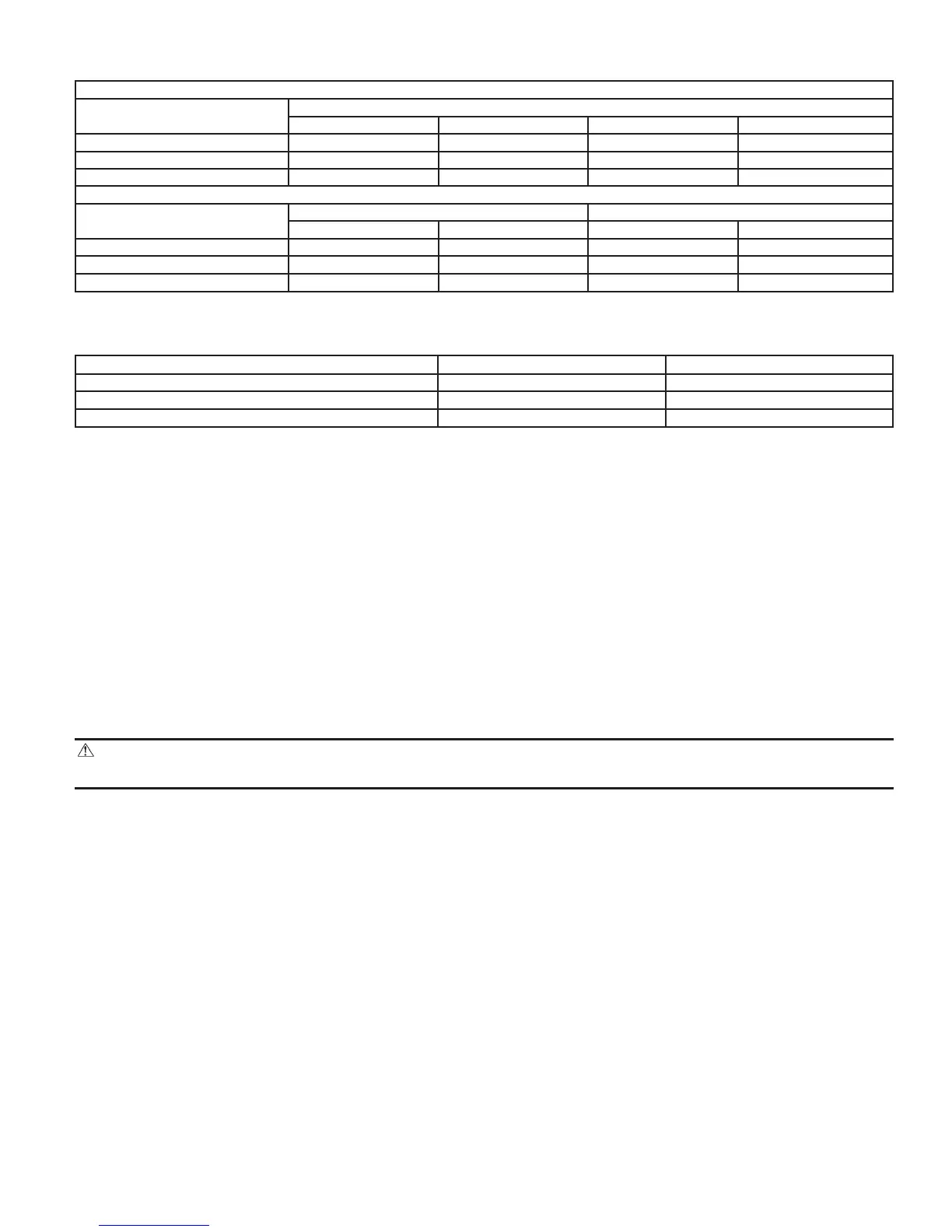

Table 7—Gas Pipe Size

NATURAL GAS

Length of Pipe — Ft.

Pipe Capacity — Btuh Input (Includes Fittings)

1/2 in.* 3/4 in.* 1 in. 1–1/4 in.

20 92,000 190,000 350,000 625,000

40 63,000 130,000 245,000 445,000

60 50,000 105,000 195,000 365,000

PROPANE GAS

Length of Pipe — Ft.

Copper Tubing Iron Pipe

5/8 in.* 3/4 in* 1/2 in.* 3/4 in.*

20 131,000 216,000 189,000 393,000

40 90,000 145,000 129,000 267,000

60 72,000 121,000 103,000 217,000

* Outside diameter

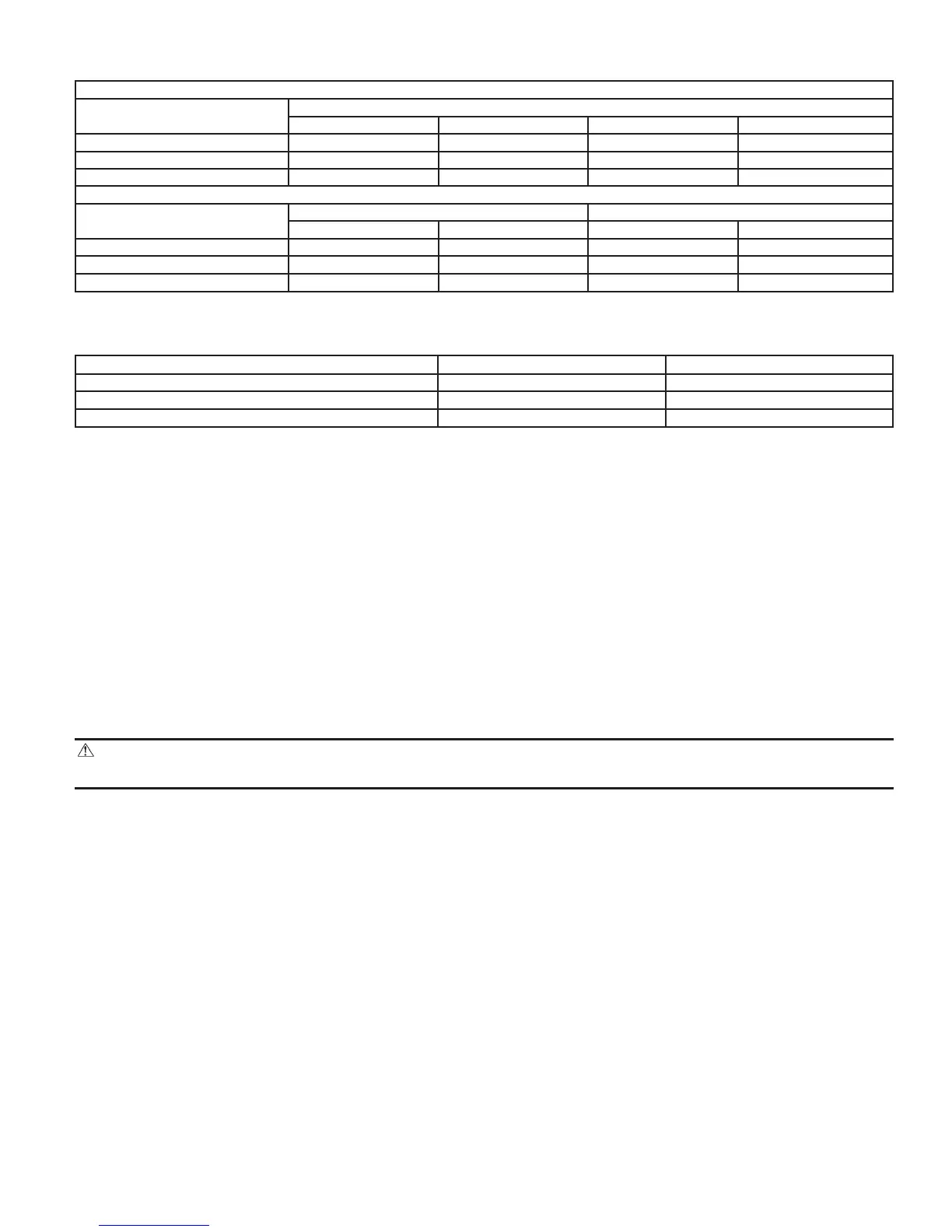

Table 8—BW9 Gas Supply Pressures

NATURAL PROPANE

Maximum Gas Supply Pressure 10-in. w.c. 14-in. w.c.

Recommended Gas Supply Pressure 7-in. w.c. 11-in. w.c.

Minimum Gas Supply Pressure 5-in. w.c. 10-in. w.c.

—19—

→

Loading...

Loading...