506 01 2303 01 11

Specifications are subject to change without notice.

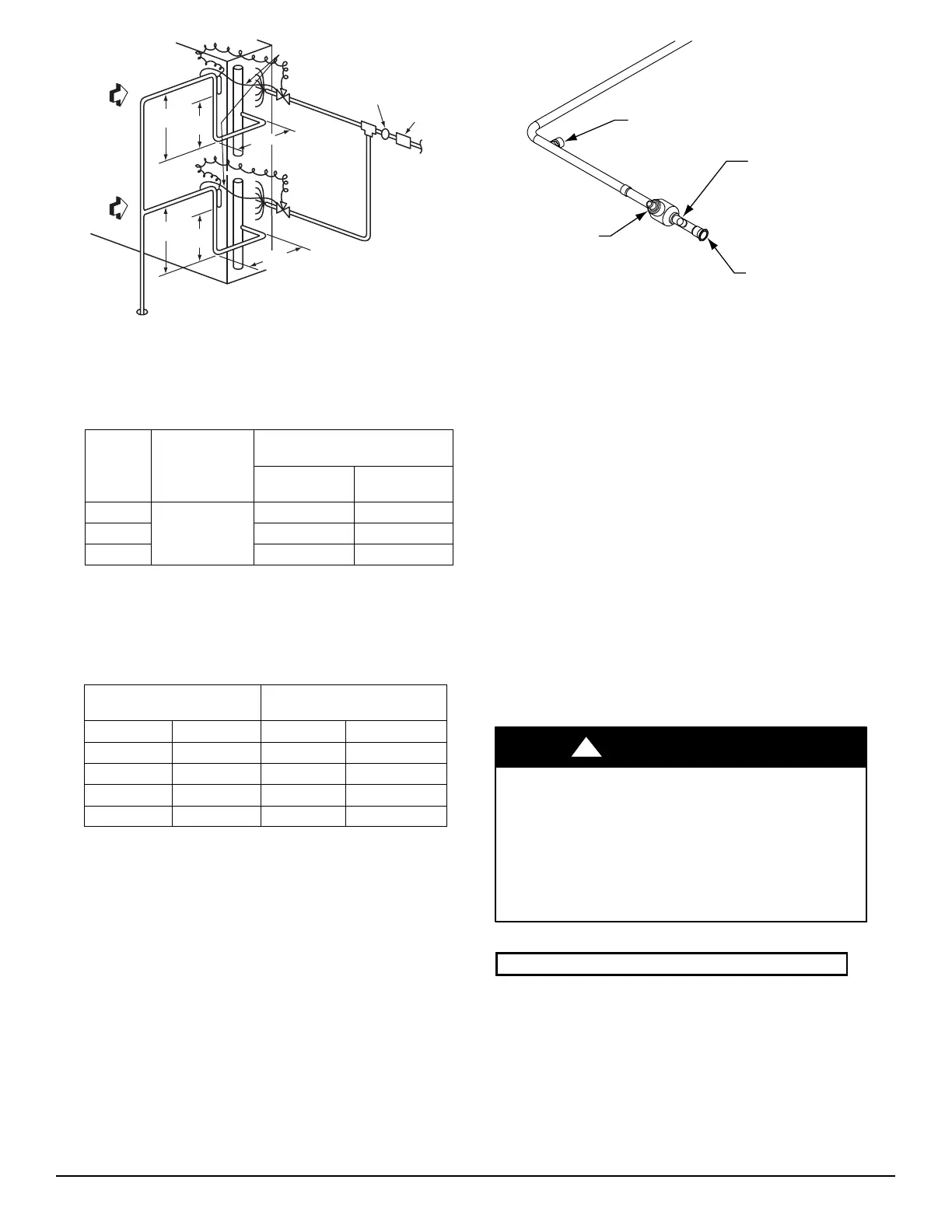

LEGEND

TXV — Thermostatic Expansion Valve

INDOOR

COIL CKT 2

AIRFLOW

INDOOR

COIL CKT 1

AIRFLOW

15 DIAMS

MIN

10

DIAMS

8 DIAMS

MIN

TXV

SENSING

BULB

EQUALIZER LINE

SIGHT GLASS

LOCATION

TXV

CKT 2

FILTER DRIE

LOCATION

TXV

SENSING

BULB

TXV

CKT 1

8 DIAMS

MIN

15 DIAMS

MIN

10

DIAMS

C11037

Fig. 6 -- Location of Sight Glass(es) and Filter Driers

(typical CHS size 121)

Table 6 – Minimum Outdoor Air Operating Temperature

UNI T

%

COMPRESSOR

CAPACITY

MINIMUM OUTDOOR

TEMP — F (C)*

Standard Unit

Head Pressure

Control

†

CHS072

100

35 (1.7) –20 (–28.9)

CHS091

35 (1.7) –20 (–28.9)

CHS121 35 (1.7) –20 (–28.9)

* Applies to Cooling mode of operation only.

† Wind baffles (field-supplied and field-installed) are recommended for all

units with low ambient head pressure control. Refer to Low Ambient

Control Installation Instructions (shipped with accessory) for details.

Table 7 – Insulation for Vapor Line Exposed

to Outdoor Conditions

LENGTH OF EXPOSED

VAPOR LINE*

INSULATION THICKNESS

†

ft m in. mm

10 3

3

/

8

10

25 8

1

/

2

13

35 11

3

/

4

19

50 15

3

/

4

19

* Recommended vapor line insulation for piping exposed to outdoor

conditions to prevent loss of heating during heating cycle. When vapor

line goes through interior spaces, insulation should be selected to pre-

vent condensation on cooling cycle. Heating capacity should be re-

duced 1000 Btuh (295 W) if over 35 ft (11 m) of vapor line with

3

/

4

in. (19

mm) insulation is exposed to outdoor conditions.

† Closed cell foam insulation with a thermal conductivity of: 0.28 Btu S

in./ft

2

S h S F (0.04 W/m S C).

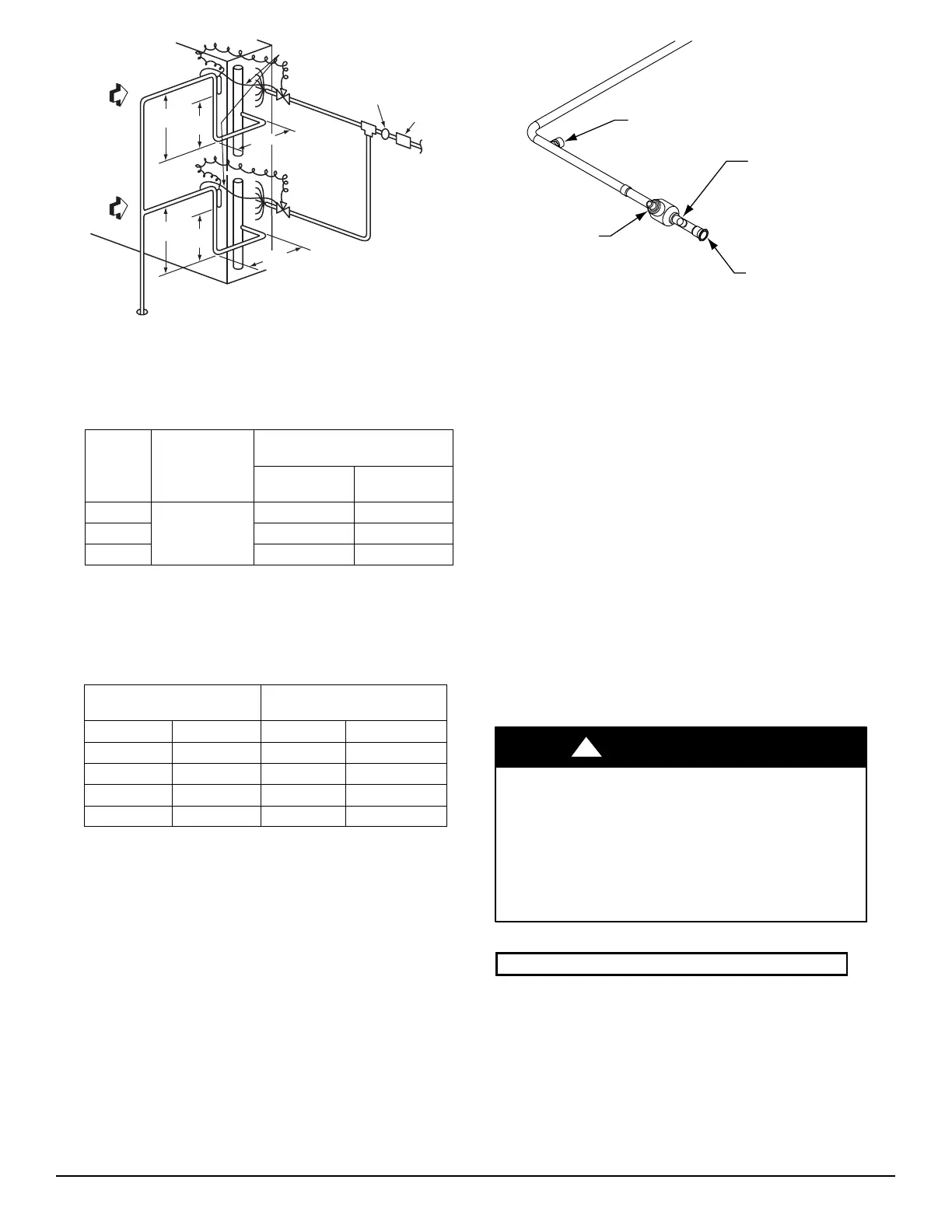

Make Piping Connections —

Piping connec tions a t the CHS unit are ball valves with

stub tube extensions. Do not open the unit service val ves

until all interconnecting tube brazing as been completed.

The stub tube connections include

1

/

4

-in SAE service fittin gs

with Schrader valve cores (see Fig. 7). Before making any

brazed connections to the unit service valves, remove both

Schrader valve caps and cores and save for re-installation.

Con nect a s ou r ce for nitrogen to one of thes e s er vice fittings

during tube brazing to prevent the formation of copper

oxides inside the tub es at brazed joints.

Factory

High-Flow

Access Port

Service Valve

with Stem Cap

Field Service

Access Port

(Schrader core)

Sweat

Connection

C150028

Fig. 7 -- Typical Piping Connection Assembly

When connecting the field tubing to the CHS service

valves, wrap the valve s in wet rags to prevent overheating

Pressure-test all joints from outdoor unit connecti ons over

to the indoor coil, using nit rogen as pressure and with

soap-and-bubbles.

When pressure-testing is completed, remove the nitrogen

source at the outdoor unit service valves and re-install the

two Schrader valve cores. Torque the cores to 2-3 in-lbs

(23-34 N-cm).

Where vapor line is e xposed to outdoor air, line must be

insulated. See Table 7 for insulation requirements.

Evacuation/Dehydration —

Evac uate and dehydrate the connec ted refrigeration

system(s) (excluding the CHS unit) to 500 microns using a

two-stage vacuum pump attached to the service ports

outside the CHS service valves, following description in

GTAC II, Module 4, System Dehydration.

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning c ould cause personal

injury, death and/or equipment damage.

R--410A refrigerant systems operate at higher

pressures than standard R--22 systems. Do not use

R--22 service equipment or components on R--410A

refrigerant equipment.

!

WARNING

IMPORTANT: Charge in Cooling mode only!

Preliminary Charge —

Before starting the unit, charge R-410A liquid refrige rant

into the high side of each CHS c ircuit through the liquid

service valve(s). The amount of refrigerant added must be

at least 80% of the operating charge listed in Table 2 for

LINEAR line length LESS the factory charge quantity (if

factory shipping charge has not been removed). See the

following example.

Loading...

Loading...