506 01 2303 01 3

Specifications are subject to change without notice.

INSTALLATION GUIDELINE

Replacement /Retrofit – R22 to R--410A

Split system heat pumps are intended to be instal led with

matching indoor sections only. The CHS heat pump

outdoor units are matc hed onl y with same-size FHS

indoor sections. Existing R-22 indoor coils cannot be

convert ed t o R-410A heat pump duty. Only the existing

refrigerant pipi ng is a candi date for retrofit use.

Acid test – If the existing system is being replaced

because of a compressor electrical failure, assume acid is

in system. If system is being replaced for any other

reason, use an approved aci d test kit to determine acid

level. If even low levels of acid are detected, install a 100

percent activated alumina suction line filter drier in

addition to the replacement liquid-line filter drier. Operate

this system in COOLING ONLY. Remove the suction line

filter drier as soon as possible, with a maximum of 72 hr

of operation.

Recom mendat ion: Install a ball valve in the liquid line at

the filter drier location when installing a suction filter in

the suction line.

Evaluate existing refrigerant piping – Reuse of existing

refrigerant piping involves three issu es : quality (strength) of

existing tubing, cleanliness and tube size. R--410A operates

at pressures that are 50 to 70% higher than the operating

pres s u res in R--22 systems . It is important that the existing

piping set be in excellent physical condition to be considered

suitable for re--use with R--410A. If the physical condition of

the existing piping set is not excellent, then remove the

existin g pipin g and replace with new piping. Refer to Step 5

for a discussion on selecting pipe sizes for these CHS heat

pumps; refer to T able 2 for recommended pipe s izes.

If the existing piping set is suitable for re-- use with

R--410A based on its condition, determine the relative

locations and elevation differences between outdoor

secti on (CHS) and indoor section (FHS) and then check

the sizes of the existing lines against the recommended

pipe sizes in Table 2 and the MAXIMUM vapor riser pipe

size use data in Table 3. Do not use pipe sizes that exceed

these maximum vapor riser sizes as oil return at part load

conditions in vertical rises may be an issue. Replace any

riser sections with reduced pipe sizes if existing pipe sizes

exceed these maximum tube size limits.

Installation –

1. Remove the exi sting evaporator coil or fan coil and

install the replacement coil.

2. Drain oil from low poi nts and traps in vapor line

tubing if they were not replaced.

3. Remove the existing outdoor uni t. Install the new out-

door unit according to these installation instructions.

4. Flush the interconnection piping system with dry

Nitrogen to eliminate as much trace of mineral oil as

possible.

5. Install the factory-supplied liquid-line filter drier at

the indoor coil j ust upstream of the TXV.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never install suction-- line filter drier in the liquid--line

of a R--410A refrigerant system.

CAUTION

!

6. If requi red, install a 100% activa ted alumina suction

line filter drier at the outdoor unit.

7. Evacuate and charge the system according to the in-

structions in this installation manual.

8. Operate the system for 10 hr. In COOLING MODE

ONLY. Monitor the pressure drop across the suction

line filter drier. If pressure drop exceeds 3 psig

(21kPa), replace suction-line a nd liquid-line filter

driers. Be sure to purge system with dry nitrogen and

evacuate when replacing filter driers. Continue to

monitor the pressure drop across suction-line filter

drier. Repeat filter changes is necessary. Never leave

suction-line filter drier in system longer than 72 hr

(actual time).

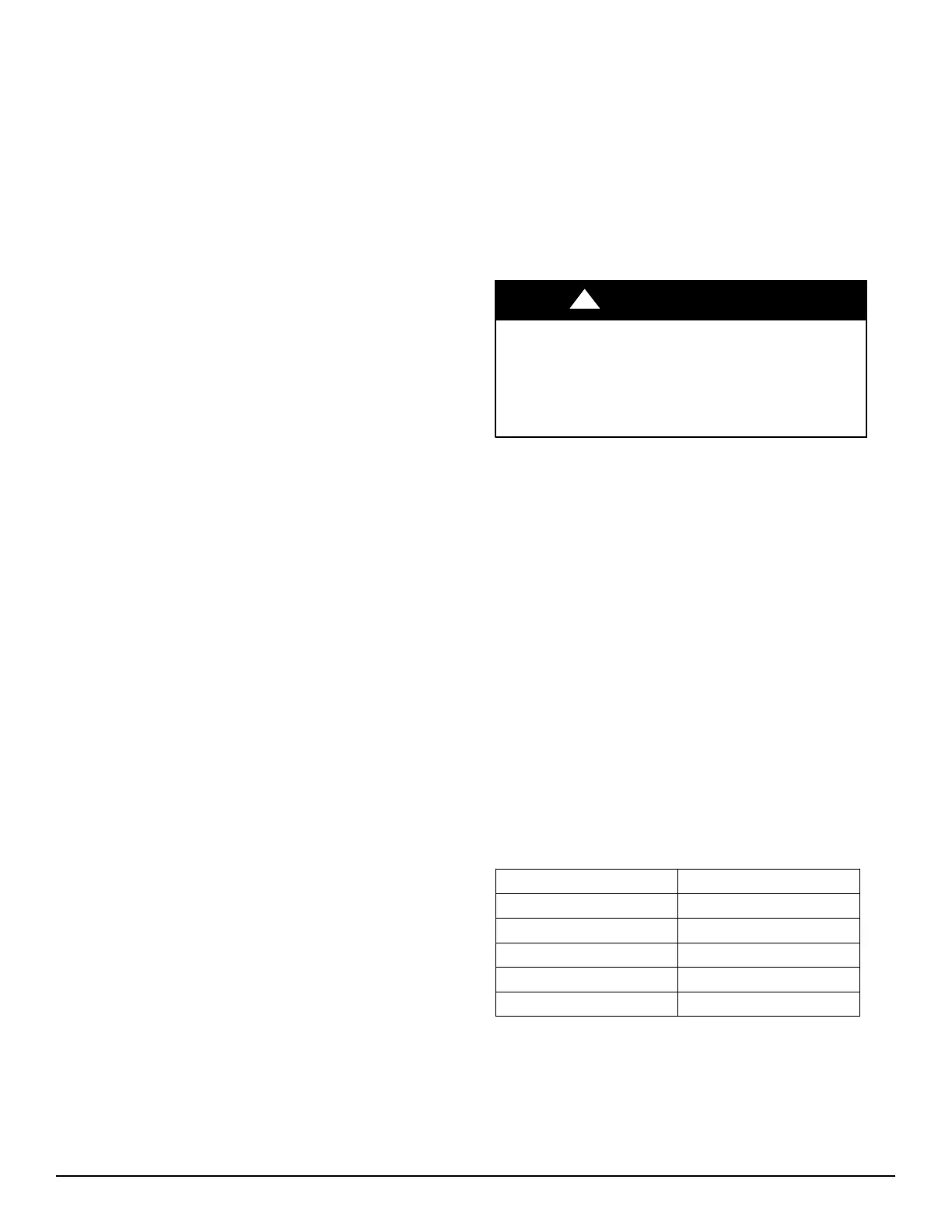

Rated Indoor Airflow (cfm)

The table below lists the rated indoor airflow used for the

AHRI efficiency rating for the units covered in this

docume nt.

CHSwithFHS

Model Numbers Full Load Airflow (cfm)

CHS072*A/B --- FHS072 2400

CHS072*G/H --- FHS072 2400

CHS091 --- FHS090 3000

CHS121*A/B --- FHS120 3000

CHS121*G/H --- FhS120 3000

Loading...

Loading...