30 506 01 2303 01

Specifications are subject to change without notice.

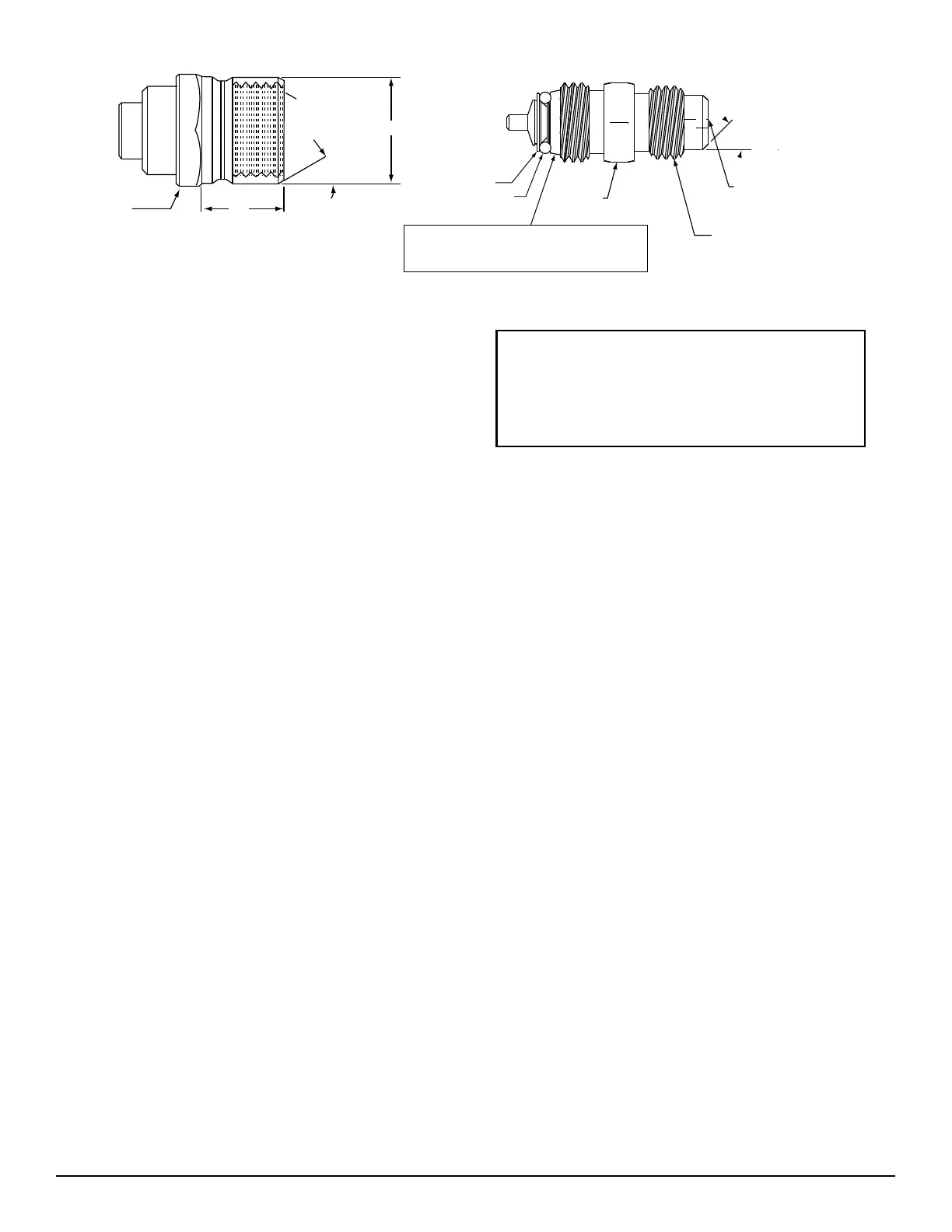

1/2-20 UNF RH

30°

0.596

.47

5/8” HEX

SEAT

CORE

WASHER

DEPRESSOR PER ARI 720

+.01/-.035

FROM FACE OF BODY

7/16-20 UNF RH

O-RING

45°

1/2" HEX

This surface provides a metal to metal seal when

torqued into the seat. Appropriate handling is

required to not scratch or dent the surface.

(Part No. EC39EZ067)

C08453

Fig. 23 -- CoreMax Access Port Assembly

Refrigerant System Pressure Access Ports —

There are two access ports in each circuit - on the suction

tube near the compressor and on the discharge tube near

the compressor. These are brass fittings with black plastic

caps. The hose connection fittings are standard 1/4 SAE

Male Flare couplings.

The brass fittings are two-piece High Flow valves, with a

receptacle base brazed to the tubing and an integral

spring-closed check valve core screwed into the base. (See

Fig. 23.) This check valve is permanently assembled into

this core body and ca nnot be serviced separately; replace

the entire core body if necessary. Service tools are

available from RCD that allow the replacement of the

chec k valve core without havi ng to recover the entire

system refrigerant charge. Apply c ompressor refrigera nt

oil to the check valve core’s bottom o-ring. Instal l the

fitting body with 96 +/-10 in-lbs of torque; do not

overtighten.

Compressor Protection

Compressor Overcurrent —

The compressor has internal limbered motor protection.

Compressor Overtemperature Protection (IP) —

The compressor has an internal protector to protect it

agai nst excessively high discharge gas temperatures.

CrankcaseHeater—

The heater prevents refrigerant migration and compressor

oil di lution during shutdown whenever compressor is not

operating. The heater is wired to cycle with the

compressor; the heate r is off when compressor is running,

and on when compressor is off.

The crankcase heater will operate as long as the power

circ uit is e nergized. The main disconnec t must be on to

energize the crankcase heater.

IMPORTANT: Never open any switch or disconnect

that energizes the crankcase heater unless unit is

being serviced or i s to be shut down for a prolonged

period. After a prolonged shutdown on a service job,

energize the crankcase heater for 24 hours before

starting the compressor.

High Pressure Switch —

The system is provided with a high pressure switch

mounted on the discha rge li ne. The switch is

stem-mounted and brazed into the discharge tube. Trip

setting is 630 10 psig (4344 69 kPa) when hot. Reset

is automatic at 505 20 psig (3482 140 kPa).

Loss of Charge Switch —

The system is protected against a loss of charge and low

evaporator coil loading condition by a loss of charge

switch located on the liquid line. The switch is

stem-mounted. Loss of Charge Switch trip setting is 27

psig 3psig(18621 kPa). Reset is automatic at 44 5

psig (303 35 kPa).

Outdoor Fan Motor Protection —

The outdoor fan motors are internally protected against

overtemperat ure.

Control Circuit, 24-V —

The cont rol circuit is protected against overcurrent

conditions by circuit breakers mounted on control

transformer TRAN1 and TRAN2. Reset is manual.

Commercial Defrost Control

The Commercial Defrost Control Board (DFB)

coordina tes thermostat demands for one stage cooling,

first stage heating, emergency heating and defrost control

with unit operating sequences. See Fig. 25 for board

arrange ment.

The DFB is located in the CHS’s main control box (see

Fig. 24). All connections are factory-wire d. Refer to

Table 9 for details of DFB Inputs and Outputs.

Loading...

Loading...