42 506 01 2303 01

Specifications are subject to change without notice.

5. Mix environmentally sound coil cleaner in a 2

1

/

2

gal-

lon garden sprayer according to the instructions in-

cluded with the cleaner. The optimum solution tem-

perature is 100F(38C).

NOTE: Do NOT USE water in excess of 130F(54C),

as the enzymatic activity will be destroyed.

6. Thoroughly apply environmentally sound coil cleaner

solution to all coil surfaces including the finned area,

tube sheets and coil headers.

7. Hold ga rden sprayer nozzle close to finned a reas and

apply cleaner with a vertical, up-and-down motion.

Avoid spraying in horizontal pattern to minimize po-

tential for fin damage.

8. Ensure cleaner thoroughly penetrat es deep into finned

areas.

9. Interior and exterior finned a reas must be thoroughly

cleaned.

10. Finned surfaces should remain wet with cleaning so-

lution for 10 minute s.

11. Ensure surfaces are not allowed to dry before rinsing.

Reapply cleaner as needed to ensure 10-minute satu-

ration is achieved.

12. Thoroughly rinse all surfaces with low velocity clean

water using downward rinsing motion of water spray

nozzle. Protect fins from damage from the spray noz-

zle.

13. Replace top cover and rear corner posts.

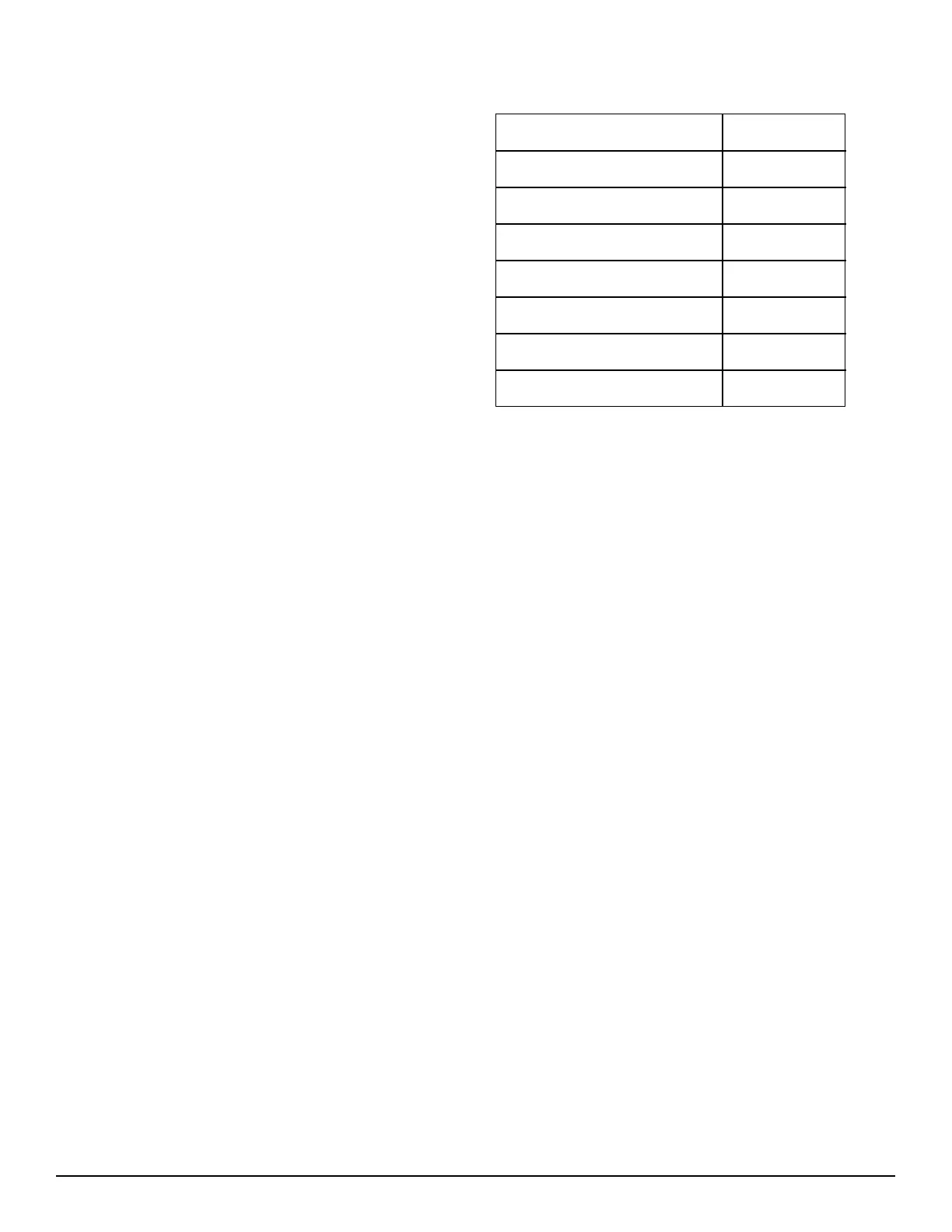

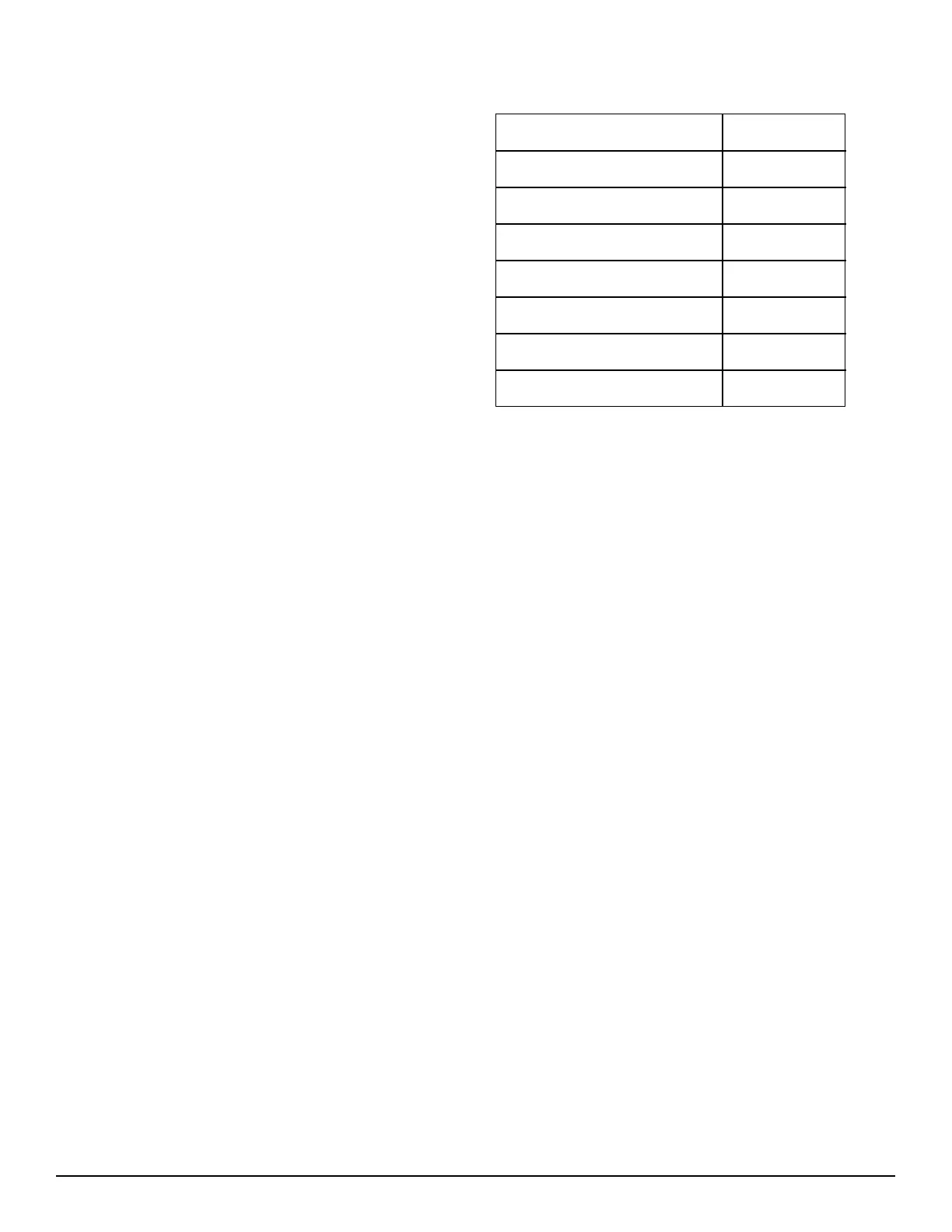

FASTENER TORQUE VALUES

Table 13 – Torque Values

Compressor mounting bolts 65--- 75 in–lbs

(734–847 N–cm)

Condenser fan motor mounting bolts 20 2in–lbs

(226 23 N–cm)

Condenser fan hub setscrew 84 2in–lbs

(949 136 N–cm)

High-flow service port 96 10 in–lbs

(1085 23 N–cm)

Schrader-type service check valve 2–3 in–lbs

(23–34 N–cm)

Compressor oil sightglass thread 330 31 in–lbs

(23–34 N–cm)

Compressor to Compressor rail torque 120–168 in–lbs

(1356–1898 N–cm)

Compressor rail to base pan torque 70 5in–lbs

(791 57 N–cm)

Loading...

Loading...