14

Install a gas supply line that runs to the unit heating section.

Refer to the NFPA 54/NFGC or equivalent code for gas pipe

sizing data. Do not use a pipe size smaller than

1

/

2

-in. Size the

gas supply line to allow for a maximum pressure drop of

0.5 in. wg (124 Pa) between gas regulator source and unit gas

valve connection when unit is operating at high-fire flow rate.

The gas supply line can approach the unit in three ways: hori-

zontally from outside the unit (across the roof), thru-curb/under

unit basepan (accessory kit required), or through unit basepan

(factory option or accessory kit required). Consult accessory

kit installation instructions for details on these installation

methods. Observe clearance to gas line components per

Fig. 16.

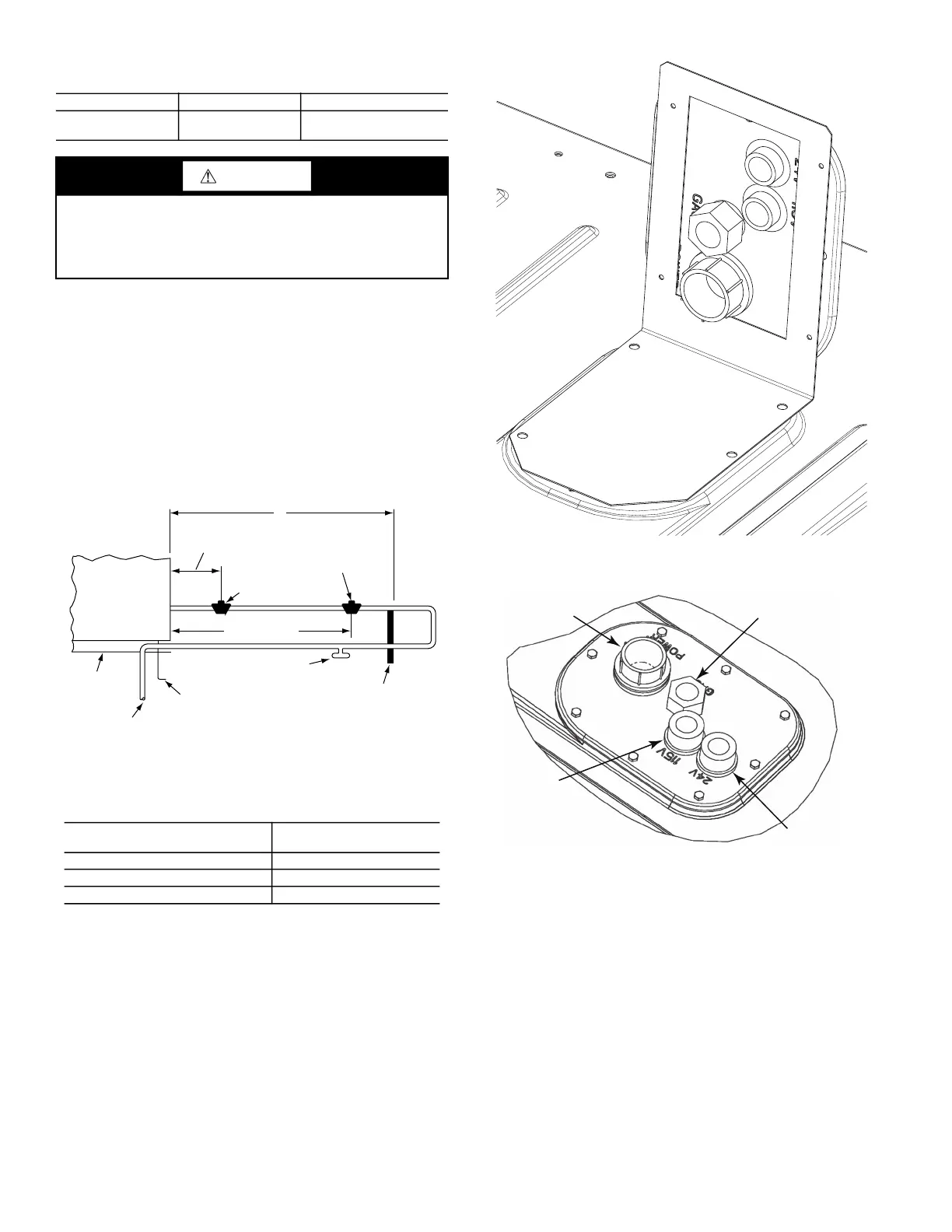

Fig. 16 — Gas Piping Guide

(with Accessory Thru-the-Curb Service Connections)

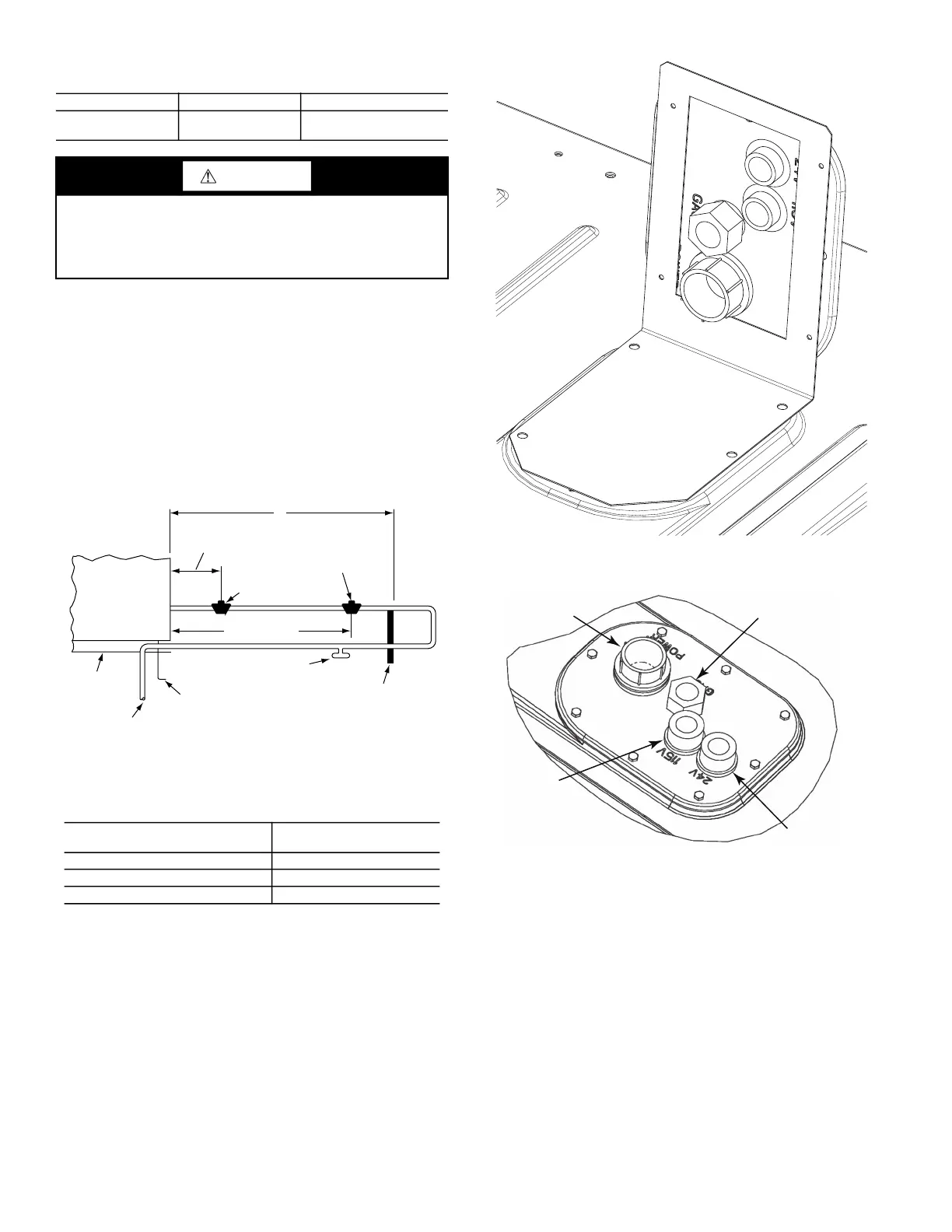

FACTORY OPTION THRU-BASE CONNECTIONS (GAS

CONNECTIONS)

This service connection kit consists of a 1/2-in. electrical bulkhead

connector and a 3/4-in. electrical bulkhead connector, connected

to an “L” bracket covering the embossed (raised) section of the

unit basepan in the condenser section (see Fig. 17 for shipping

position).

The 3/4-in. bulkhead connector enables the low-voltage control

wires to pass through the basepan. The 1/2-in. bulkhead connector

allows the high-voltage power wires to pass through the basepan.

See Fig. 18.

Fig. 17 — Thru-the-Base Fitting Assembly (Shown in

Shipping Position)

Fig. 18 — Thru-Base Connection Fittings

1. Remove the “L” bracket assembly from the unit.

2. Remove connector plate assembly from the “L” bracket

and discard the “L” bracket, but retain the washer head

screws and the gasket (located between the “L” bracket

and the connector plate assembly).

NOTE: Take care not to damage the gasket, as it is reused in the

following step.

3. Place the gasket over the embossed area in the basepan,

aligning the holes in the gasket to the holes in the basepan.

See Fig. 18.

4. Install the connector plate assembly to the basepan using 8

of the washer head screws.

The thru-base gas connector has male and female threads. The

male threads protrude above the basepan of the unit; the female

threads protrude below the basepan.

Table 4 — Natural Gas Manifold Pressure

UNIT MODEL UNIT SIZE MANIFOLD PRESSURE

581K*--F 04, 05, 06

3.2 in. wg

(797 Pa)

CAUTION

EQUIPMENT DAMAGE

Failure to follow this caution may result in equipment damage.

When connecting the gas line to the unit gas valve, the installer

MUST use a backup wrench to prevent damage to the valve.

X

BASE UNIT

BASE RAIL

ROOF

CURB

9” MINIMUM CLEARANCE

FOR PANEL REMOVAL

MANUAL GAS

SHUTOFF VALVE

*

GAS

REGULATOR

*

48” MINIMUM

DRIP LEG

PER NFGC

*

FIELD-FABRICATED

SUPPORT

*

FROM

GAS

METER

LEGEND *Field supplied.

NFGC —

National Fuel Gas

Code

NOTE: Follow all local codes.

STEEL PIPE

NOMINAL DIAMETERS (IN.)

SPACING OF SUPPORTS

X DIMENSION (FT)

1

/

2

6

3

/

4

or 1 8

1

1

/

4

or larger 10

LOW VOLTAGE

CONDUIT

CONNECTOR

HIGH VOLTAGE

CONDUIT

CONNECTOR

BRASS FITTING FOR

3 TO 6 TON UNITS

AUXILIARY

POWER

SUPPLY

(OPTIONAL)

Loading...

Loading...