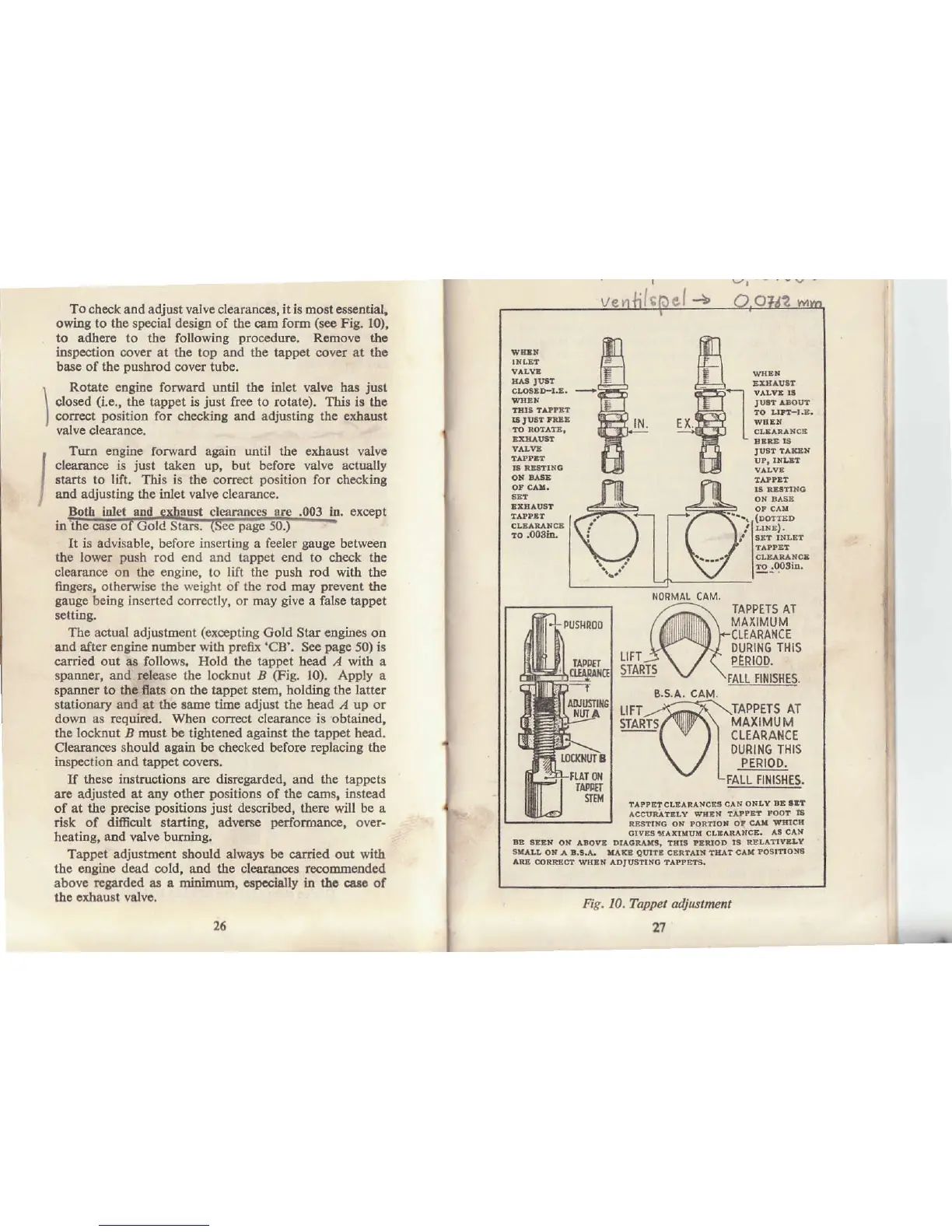

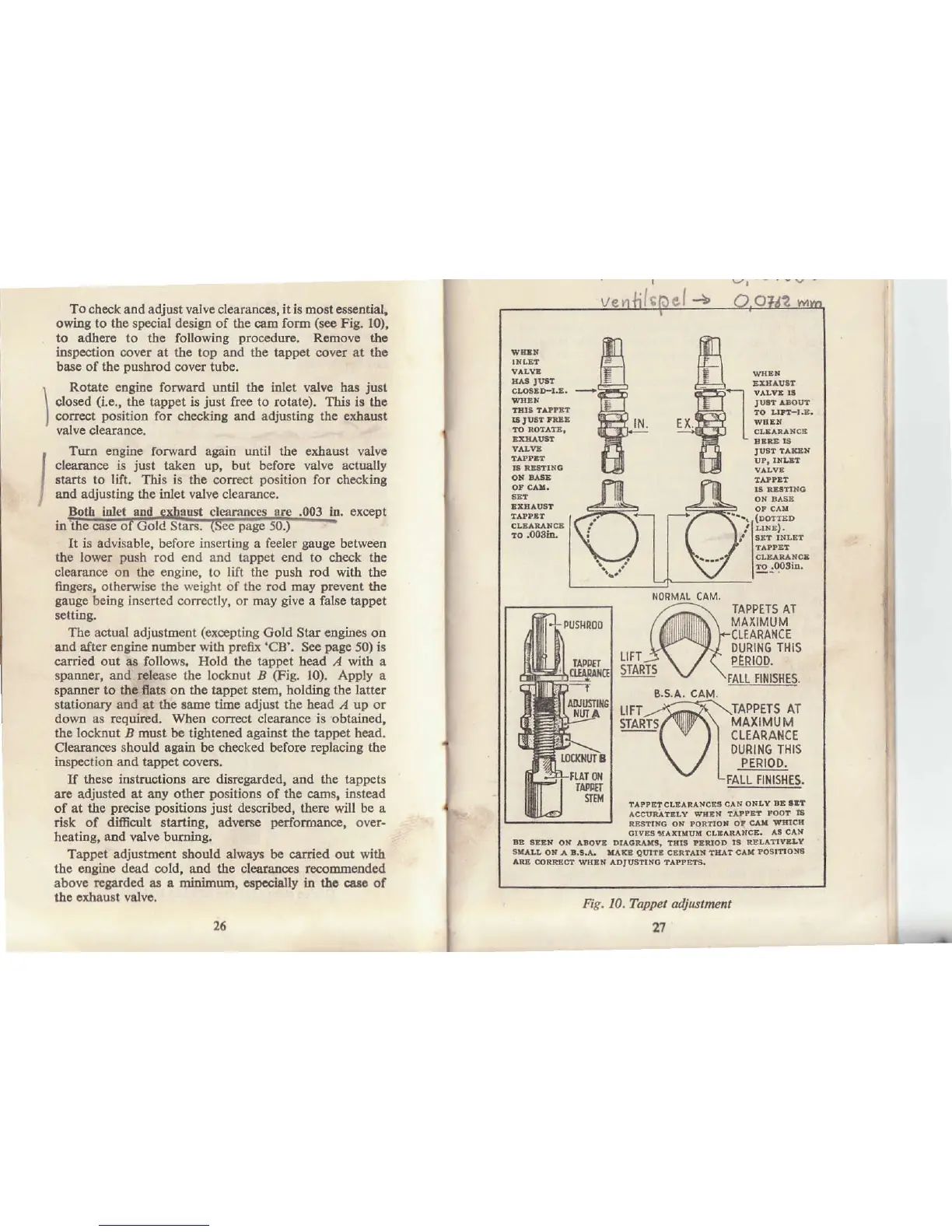

To check

and adjust valve clearanoes, it i!

host eslential,

owing to the

special

design of the cam form

(sc€

Fig. lO),

to adhcle to the

following

procedure.

Romove thc

inspection cover at the top and the tappet cover .t tho

base of the

pushrod

cover tubo.

I

Rotate enginc

forward until rbc idet vslve bas

just

I

closed

(i.e.,

tbe tappet

is

just

frec

to

rotate). Thir is tha

I

corrcct

position

for

che.kiDg and adjusting

thc exhrurt

'

valve clearance.

I

Tum cngine forward agBin until the exhausl valve

I

clearance is

just

tak€n

up, but beforc

valve actuslly

I

slarts to lift.

This

is tbe

cor.ect

positjon

for checkinS

J

and adjusting the inlet valvc clearance.

'

Both htet and exhaust cleamnces

are

,003 ltr. exceDt

ln the

cåse oI

(iotc

5tius.

(tee

page

Ju.,

It is advisable, b€fore inscrtirg a feeler

gaugo

between

the lower

push

rod €nd and tappet end to ch€ck thc

clearance

on the

ongine,

to

lift the

push

rod with the

fngers,

otheipise

the weight of the rod may

prevent

thc

gauge

being inserted corectly, or may

give

a falso tåppet

sctuDg.

Thc actual adjultment

(excepting

Gold Star

cngiDes

otr

atrd afte! engine truDbcr with

prefii

'CB'. S€€

page

50)

is

carriod out a8

follows.

Hold the tappet head ,4 with a

spantrer, and rclease the locknut B

(Fig.

1O). Apply a

spatrocr to tha ats oo the trppet stem, holdiog the

latt€.

statioDary aDd at the lamc ti[re adjust the head I up or

dowD as requfuid. When correct clearance is obtained,

the locknut

,

must be tighteDed against the tappet heåd.

Clearances

should agaitr be checked before replacing the

inspeatioo and tlpp€t cavers.

If

thcse instrugtions are disregarded,

and

the tappets

are adjusted

at

aDy

other

positions

of the ca$s, insteåd

of at tle

precise positions

just

described, there will be a

rfuk of dificlrlt startiag, adrc$e

perfomatrce,

ov€.-

heating, and valv€ buming.

Tappet adjustment should always b€ cå.ried out with

thc eagine dead cold, sud the clearances r€coomended

above

rgarded

a! a

miniqum,

ospacis[y h tho oaro of

thc

cxhaust valvc.

I

ro .008iD"

FALL FINISHES.

^ccvnrltl,?

BE

r^ia

om.E

cERtar!

tE^t

clf

rosrtlox!

^E

coRFlct wHrN rDtus

B.S.^. CAM.

l

Fig. 10. Tappet adjustmen

a1

Loading...

Loading...