Connect

up the oil feed and

rctum

pipes

to

the rocke.s

and inlet rocker box, Replace

engine steadying

stay.

Replace

the rocker box covers, the carburetter,

the

exhaust

pipe

and silencer,

and fnally, the

petrol

tank

and

petrol pipe.

It

is advisable to remove the sparking

plug

aDd clean

it

beforc

replacing.

(see page

34.) Check

that the

gap

between

the

points

is conect and adjust

, ,

iI Decessary,

/tqh["

d#få,n.

p!{fqY.

u,.,.-ou.o ror aoy

reason

nore rhat th"e

engine'l$lift

pinion

and cam

pinions

are

marked to faoilitate assembly.

As the cams are

inter-

changeable

the timing marks are

duplicated on both

pinions.

The 'dash' mark only

is

used for

the inlet cam

and

the 'dot'for the cxhaust

cam

(see

Fig. l7). These

instructions apply equally to Competition

engines.

_

{For Cold

Stars fitted

with

specjal cams

sce

page

52.)

Aat.a

hDFhAuq'|t^q

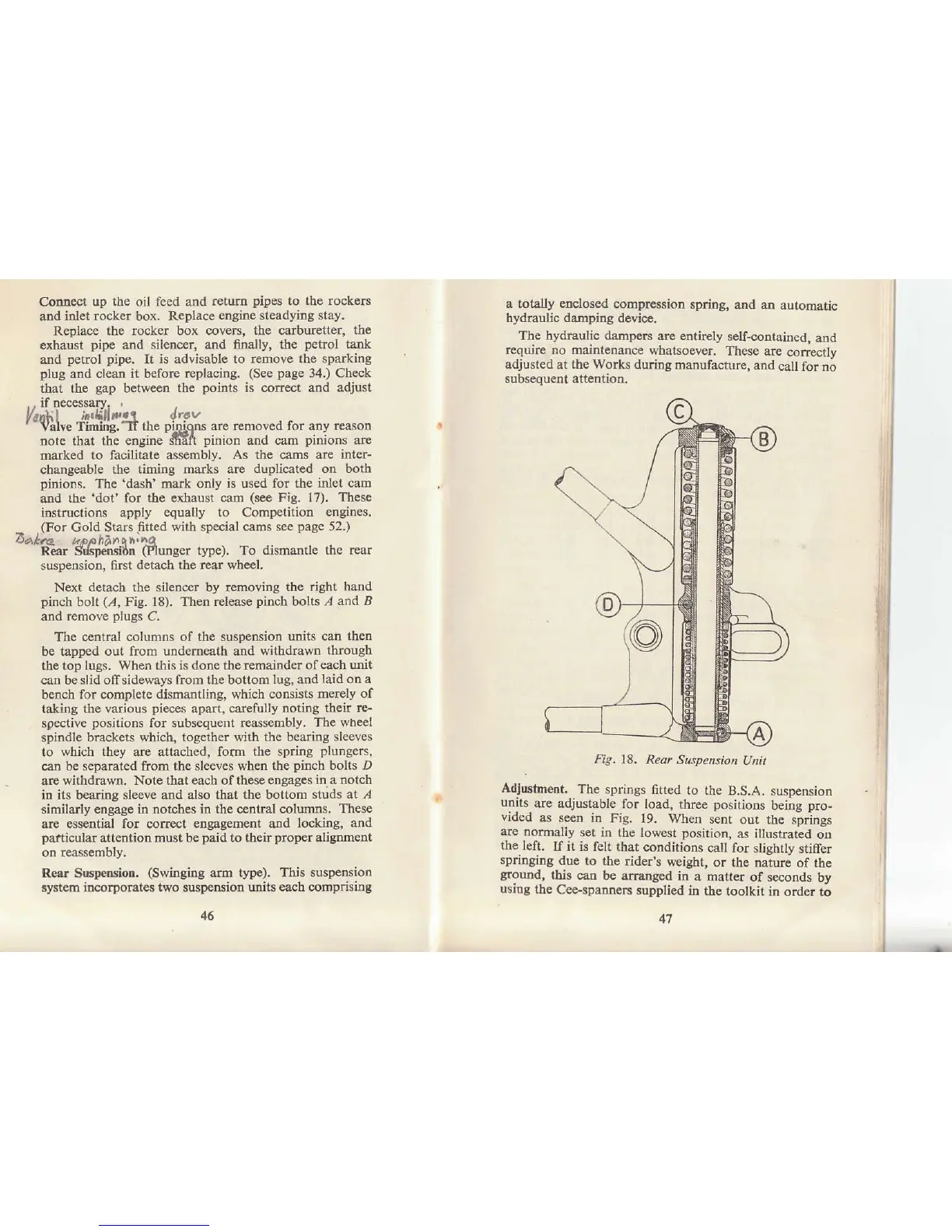

Rear Sdspensibn

(Plunger

type), To

dismantle the rear

suspension,

first detach the rear wheel.

Next detach the silencer by removing

the right

hand

pinch

bolt

(.4,

Fig. 18). Then

rclease

pinch

bolts .4

and B

and remove

plugs

C.

The central

columns of the suspension

units can theD

be tapped

out from undemeath and withdøwn

through

the

top lugs. When this is done the remainder

of each unit

can beslid offsideways from the bottom

lug, and

laid

on

a

bench

for complete dlsmantling,

rvhich consists merely

of

taking the

vadous

pieces

apart, caxefully noting

thek rc-

spective

positions

for subsequent reassembly,

The wheel

spindle bruckets

which, together with the bearing

sleeves

to

which they aæ attached, form the spring

plungers,

can be

separated fiom the sleeves when

th€

pinch

bolts D

arc

withdlawn. Note that each of these

engages in a notch

in its bea.ridg sleeve and also that the botlom

studs at .4

simila.rly etrgage in notches in the central

columns. These

are essential for corect engagement and

locking, and

pafticular

attention must

be

paid

to their

proper

aliSnment

on r€assembly.

Reår Suspension.

(Swinging

alm type).

This suspension

system incorporates two suspension units

each cornprising

a

totally

etrclosed

compression

spriog,

4nd atr automatic

hydraulic damping

device.

The hydraulic

dampe$

are entirely

self-contained,

and

require no maintenance

whatsoever.

These aæ

conectly

sdjusted

at

the Works

dufing manufactute,

alld

call for no

subsequent attentioo.

Fig. 18.

Rear Suspensiott

Unil

Adjustment.

The

springs fifted

to the

B.S.A. suspeosion

units

are adjuslable

for load, rhree

positioos

being

pro-

vrdecl

as

seen in Fig.

19. When \ent

out tbe springs

are normally

set irl the lowest

position,

as illustrated

on

the

left.

If it is

felt that

conditions

call for slishtlv

stifer

springing

due to

the rider's weighr,

or the naiurj

of tle

ground,

this can

be arranged

in a mattet

of seconds

by

using

the

Cee-spanneN

supplied

in

the toolkit in

order to

46

41

Loading...

Loading...