r

I

grease

during assembly and wll last until the

machine is

in need of a complete overhaul.

MAGNETO.

Cleanlng

and Adiushnent. About

every 3,m0 miles

lemove the contact breaker covet and

examine the

contact breaker. If the contacts are burned

or blackened.

clean them with 6ne carborundum

stone or fine emery

cloth and afterwards

wipe away dust or dirt with a

petrol

moistened cloth. Check

the

contact

breaker setting afler

cleaning.

To check the coDtact

breaker setting, tum the

etrgine

until the contacts

are fully opened and

insert the

gauge

provided

on the ignition

spanner. If the setting is corect

(.012

to .015 in.) the

eauge

should be a sliding fit. Ii how-

ever, the

gap

vades appreciably

from the

gauge,

slackeD

the locknut on the

fixed contact and tum the contact

screw until the

gap

is set to the

gauge.

Final,J tiSbteD

the

locknut.

Next

examine the

pick-up,

which can

be rcdoved

when the fixing screws zue withdmwn, See

that the

pick-up

brush moves freely

and while it is removed,

clean the slip ring

track and flanges with a soft dry

cloth.

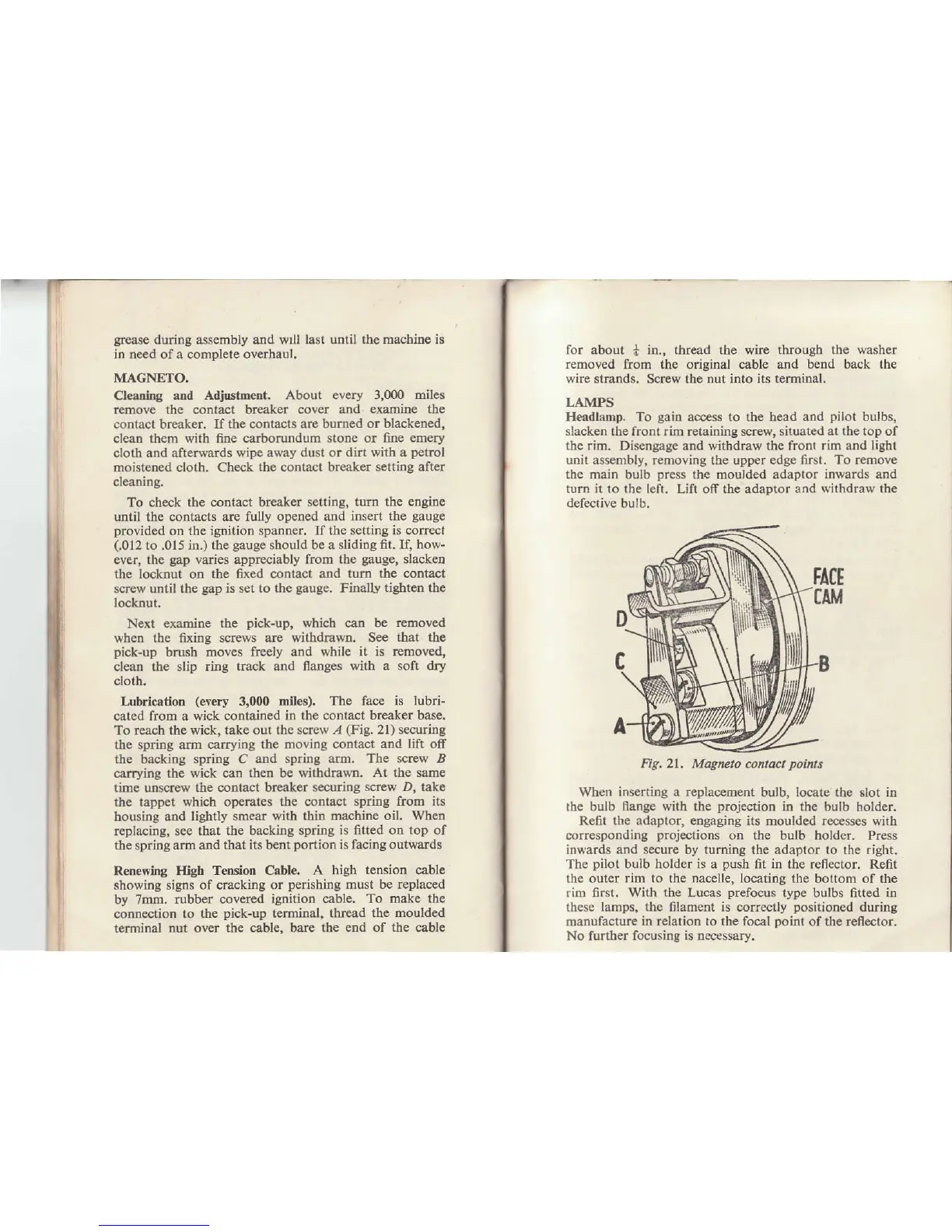

Lubrication

(every

3,000 miles). The face

is lubri-

cated

from

a

wick contained in the contact

brcaker base.

To reach the wick, take out the søew

,4

(Fig.

21) securing

the sp ng arm carrying the

moving contact and lift ofr

the

backing

spiing C

and spring arm. The screw B

carrying the

wick can then be rrithdrawn.

At the

same

time unscrew

the contact breaker seculing

screw D, take

the lappet

which operates the contact

sping fiom its

housing and

lightly smear with thin

machine oil. When

replacing, see

that the backing spring

is fitted on top of

the

spring alm

and that its bent

portion

is facing outwards

Renewing High

Tension Cabl€. A

high tension cable

showing signs

of cracking or

perishing

must be rcplaced

by

7mm. rubber covered

ignition cable. To

make the

connection

to the

pick-up

terminal, thread the

moulded

terminal nut over

the cable. bare the

end

of

the

cable

,

for

about

*

in., thread the wire

tbrough the washer

r€moved

from the original cable and

bend

back

the

whe strands. Screw the nut into

its

termiDal.

LAMPS

Heådlåmp.

To

gain

access to the bead

and

pilot

bulbs,

slacken the

front rim retaining screw,

situated at the top of

the rim. Disengage

and withdraw

the front rim and light

uni! assembly, removing

the

upper edge firsl. To remove

the main bulb

press

the

moulded

adaplor inwards and

turn it lo the letr. Lift off the adaptor and rithdraw the

defective bulb.

When inserting a replacement bulb, Iocate the

6lot

in

rhe bulb llange with the

projection

in the bulb

holder.

Refit the adaptor, engaging its moulded recesses wirh

corresponding

proje.tions

on the bulb holder.

Press

inwards and secure by turning the adaptor to the n'ght.

The

pilot

buib holder

is

a

push

fit

in

the reflector, Refit

thc outer

rim to

the

nacelle, Iocating

the bottom of the

rim 6rst. With the Lucas

prefocus

type

bulbs fitted

in

these lamps, the filament is coffectly

positioned

during

manufacture in relation to the focål

poinl

of

the reflector.

No further focusing is necessary.

Fig,2l, Magneto contact

points

Loading...

Loading...