Do you have a question about the Bunn DUAL and is the answer not in the manual?

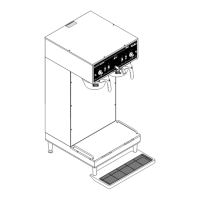

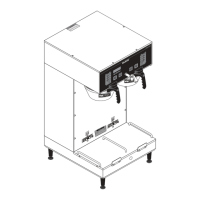

Details the functionality of the coffee brewer, including batch sizes and faucet.

Outlines the warranty terms, conditions, and exclusions for Bunn-O-Matic equipment.

Provides critical safety warnings for brewer operation, including hot contents and decanter integrity.

Highlights essential safety rules for water tank, electrical circuits, and grounding.

Specifies voltage, amperage, and phase requirements for electrical hookup.

Steps and cautions for connecting the brewer to the electrical supply.

Details water supply pressure, line size, and connection procedures.

A critical safety warning to disconnect power before initial setup procedures.

Specific initial setup instructions for electronic and electro/mechanical models.

Reference chart for mechanical bypass percentage versus needle valve turns.

Instructions for modifying and setting brew volumes, including disabling programming.

Description of key controls like brew selector, ON/OFF, and start switches.

Step-by-step guide for brewing coffee, from selecting batch size to discarding grounds.

Guidance on cleaning brewer surfaces and sprayheads, with a note for hard water areas.

Safety precautions for servicing electrical components of the brewer.

Identifies causes and remedies for the brewer failing to power on.

Diagnoses and resolves issues preventing the brew cycle from initiating.

Further troubleshooting steps for brew cycles that fail to start.

Troubleshooting guide for when the automatic refill system is not functioning.

Diagnoses and resolves issues with inconsistent beverage levels.

Troubleshooting steps for water flowing continuously into the brewer's tank.

Identifies causes and remedies for water not reaching the optimal brewing temperature.

Further troubleshooting for water not reaching the correct temperature.

Diagnoses and resolves issues with the server warmer's heating element.

Troubleshooting for spitting or unusual steaming from sprayheads or air vents.

Troubleshooting steps for variations in the beverage level in the server.

Steps to resolve problems with inconsistent beverage levels in the server.

Troubleshooting for beverage levels that are consistently too high or too low.

Diagnoses and resolves problems causing dripping from the sprayhead.

Troubleshooting steps when water overflows the coffee filter.

Resolves issues where the beverage overflows the server.

Identifies causes and remedies for weak beverage output.

Further troubleshooting steps for weak beverage output.

Troubleshooting steps for identifying and resolving unusual noises from the brewer.

Emphasizes safety for qualified personnel performing inspection, testing, and repair.

Instructions on how to access internal brewer components for servicing.

Specifies the location of the bypass valves within the brewer's hood.

Detailed steps for testing the functionality and electrical response of the bypass valve.

Step-by-step guide for removing and installing a new bypass valve.

Identifies the location of the brew selector switches on the brewer's hood.

Instructions for testing the continuity and operation of the brew selector switch.

Guidelines for removing and installing a new brew selector switch assembly.

Specifies the location of the contactor assembly within the brewer.

Test procedures for the contactor assembly with mechanical thermostats.

Test procedures for the contactor assembly with electronic controls.

Steps for removing and replacing the contactor assembly.

Identifies the location of the control thermostat on the brewer's component bracket.

Detailed steps for testing the control thermostat's voltage and operation.

Instructions for removing and installing a new control thermostat.

Specifies the location of the dispense valves within the brewer's hood.

Detailed steps for testing dispense valve voltage, continuity, and coil action.

Step-by-step guide for removing and installing a new dispense valve.

Identifies the location of the electronic control assembly on the brewer's bracket.

General description of the electronic system controlling liquid level and temperature.

Explanation of the brew start-lock feature, requiring water to reach temperature.

Troubleshooting guide for when the liquid level control causes overflows.

Troubleshooting steps for the liquid level control system failing to refill.

Detailed test procedure for the liquid level control system.

Flow charts for diagnosing and resolving water temperature control issues.

Guide to troubleshoot why the brewer's water is not reaching the desired temperature.

Diagnoses and resolves issues where the brewer's water is boiling excessively.

Detailed steps for testing the brewer's temperature control system.

Instructions for removing and installing the electronic control assembly and sensor.

Steps for removing and replacing the triac assembly, including compound application.

Procedure for testing the continuity and operation of the grinder selector switch.

Detailed test steps for the electro/mechanical level control board and probe.

Instructions for removing and installing the level control board.

Identifies limit thermostat location and provides testing procedures.

Step-by-step guide for removing and installing the limit thermostat.

Identifies ON/OFF switch locations and provides test procedures.

Instructions for removing and installing the ON/OFF switches.

Locates the switch and notes access requirements for testing.

Steps to test the overflow protection switch for continuity and float function.

Instructions for removing and installing a new overflow protection switch.

Describes relay locations for electro/mechanical and electronic brewers.

Detailed steps for testing relays in electro/mechanical controlled brewers.

Steps for testing the relay in electronically controlled brewers.

Instructions for removing and installing brewer relays.

Identifies solenoid valve location and provides test procedures for voltage and continuity.

Step-by-step guide for removing and installing a new solenoid valve.

Identifies start switch locations and provides test procedures for continuity.

Instructions for removing and installing the momentary start switches.

Steps to test tank heaters on electro/mechanical models.

Steps to test tank heaters on electronic models.

Instructions for removing and replacing the tank heaters.

Note regarding operating temperature requirement for ECA model timers.

Detailed steps for testing early model timer voltage and continuity.

Instructions for removing and installing early model timers.

Note regarding handling the timer board during installation.

Steps to test late model timers for voltage and operation.

Instructions for removing and installing late model timers.

Guidance on setting brew volumes and disabling programming on late timers.

Procedure to adjust brew volumes by modifying timer settings.

Procedure to set specific brew volumes using the late timer controls.

Instructions for enabling the feature to prevent changes to programmed brew times.

Steps to test warmer elements for voltage and continuity.

Instructions for removing and installing warmer elements.

Wiring schematic for dual brewer with two-grinder interface.

Wiring schematic for dual brewer A & B with two-grinder interface.

Wiring schematic for dual brewer ECA with two-grinder interface.

Wiring schematic for dual brewer A & B ECA with two-grinder interface.

Wiring schematic for dual brewer with one-grinder interface.

Wiring schematic for dual brewer ECA with one-grinder interface.

Wiring schematic for dual brewer A & B with one-grinder interface.

Wiring schematic for dual brewer A & B ECA with one-grinder interface.

Wiring schematic for dual brewer with digital brewer control.

| Brand | Bunn |

|---|---|

| Model | DUAL |

| Category | Coffee Maker |

| Language | English |

Loading...

Loading...