ITCB-DV HV Training

12

Filling System

The ll system maintains the level of water in the brewer’s tank. Anytime water is drawn off of the tank during a brew

cycle or from the hot water outlet, the ll circuit activates to rell the tank.

The ll system consists of:

• 120VAC Solenoid Inlet Valve

• Flow Control

• Fill Probe

Water enters the rear of the brewer from the supply line and rst

goes through a plastic strainer mounted in the combination inlet so-

lenoid/dilution solenoid assembly. From the solenoid valve the water

ows through a .75 gallon per minute ow control washer and then

into the bottom of the water tank.

The 120VAC solenoid inlet valve is activated by the control board

anytime the brewer calls for water. The valve opens and allows

water to ow, under line pressure, to the tank where the silicon tube

connects to a ll tube attached to the tank.

The control board monitors the level of water in the tank through a

low voltage level probe mounted to the top of the tank. The control

board grounds a 2.5VAC signal to the tank through the water. If it

looses this signal, the control board will activate the inlet valve.

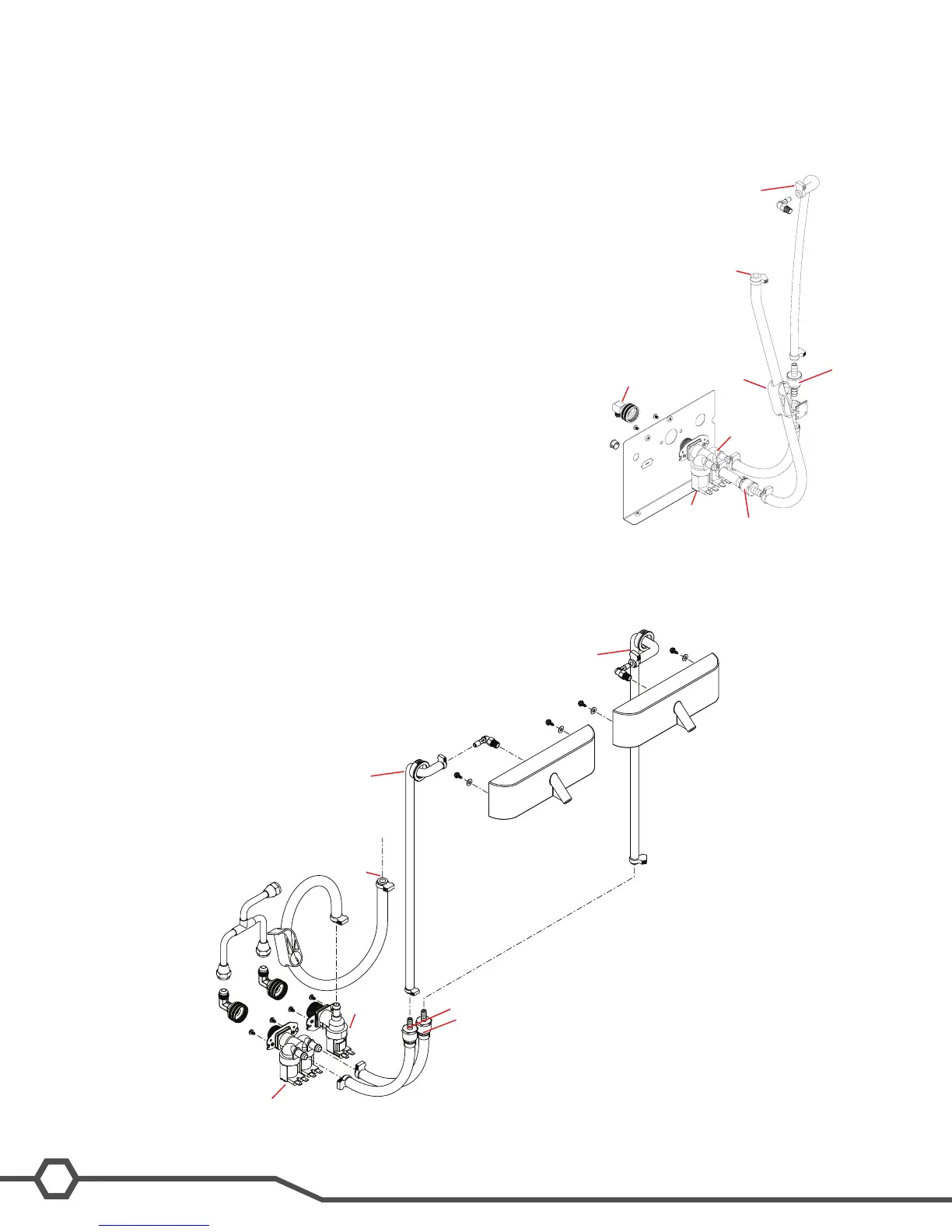

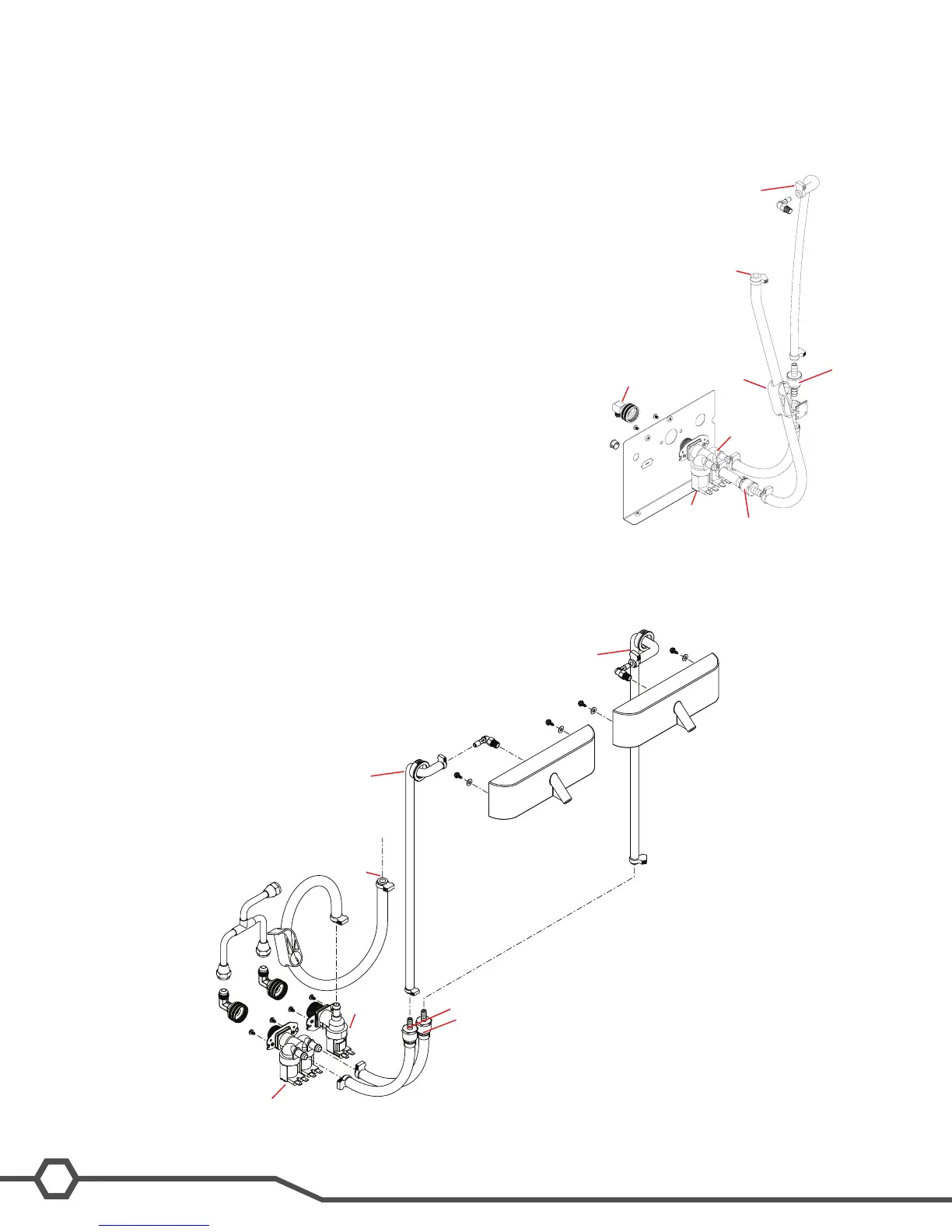

ITCB Twin HV

Tube

Clamp

To Dilution

Nozzle

To Tank

.50 GPM

Flow Control

.750 GPM

Flow Control

Inlet

Solenoid

Dilution

Solenoid

Inlet Connection

Adapter

To tank

To Dilution

Nozzle

.50 GPM

Flow Control

Inlet

Solenoid

Dilution

Solenoid

To Dilution

Nozzle

To Tank

Loading...

Loading...