8

5.2 Fluidic installation

Installation position: any, preferably actuator face up.

Flow direction (for normally closed/Safety Shuto Valves): The

letters on the valve body state the pressure (P) and outlet (A).

For normally open valves (not for Safety Shuto Valves): The letters

on the valve body state the pressure (P) and outlet (B).

→ Clean pipelines and ange connections.

→ Install dirt trap at the valve inlet (0.2...0.4mm).

Observe ow direction: from 1 (P) → 2(A) (WWA)

from 1(P) → 2(B) (WWB).

Valve with threaded connection:

→ Use PTFE tape as a seal material.

NOTE!

Caution! Risk of breakage!

▶ Do not use the coil as a lever arm.

→ Hold the valve using a corresponding open-end wrench and

screw into the pipeline.

Valve with ange connection:

→ Remove cover plate.

→ Loosen nut and remove coil.

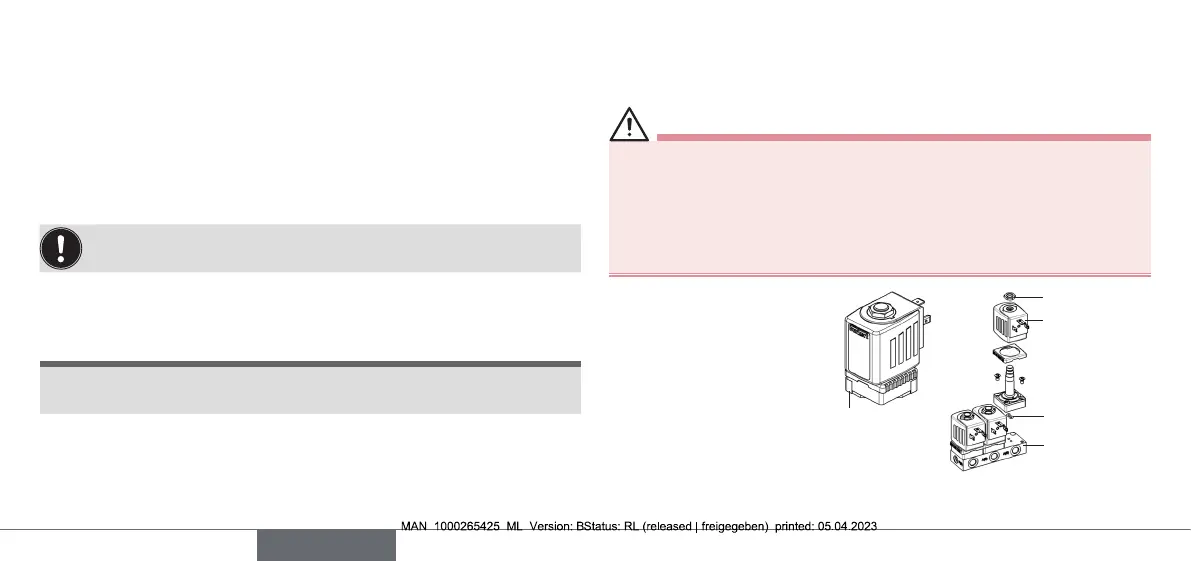

WARNING!

Danger due to escaping medium!

Leaking connections if the seals are not tted precisely, if the man-

ifold is uneven or if the surface quality of the manifold is inadequate.

▶ Make sure that the seals provided t the valve properly.

▶ Make sure that the manifold is even, with adequate surface

quality.

→ Insert the seal into the

valve body.

→ Screw valve body to

manifold (max. 1.5 Nm).

→ Mount coil and attach

nut (max. 5 Nm).

Seal

Nut

Coil

Cover plate

Manifold

English

Loading...

Loading...