10

5.4 Rotate the coil

WARNING!

Risk of injury due to electric shock.

If there is no protective conductor function between the coil and

the body, there is a risk of electric shock.

▶ Check the protective conductor function after installing the coil.

Overheating, risk of re.

Connecting the coil without installing the armature will lead to

overheating and will destroy the coil.

▶ Only connect the coil after the armature has been installed.

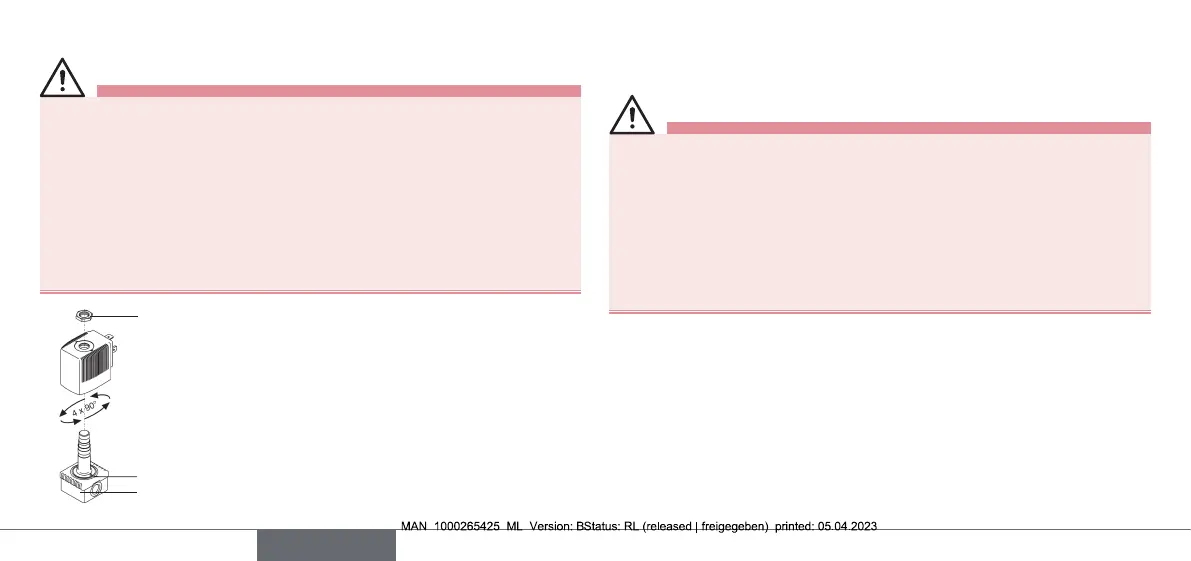

Nut

max. 5 Nm

O-ring

Armature

The coil can be rotated 4 x 90° (only 2 x

180° with block installation).

Procedure:

→ Loosen the nut.

→ Rotate the coil.

→ Tighten the nut using an open-end

wrench (tightening torque

max.5Nm).

6 MAINTENANCE, TROUBLESHOOTING

6.1 Safety instructions

WARNING!

Risk of injury due to improper maintenance work.

▶ Maintenance work may be carried out by authorised techni-

cians only, with the appropriate tools.

Risk of injury due to unintentional activation of the system and

uncontrolled restart.

▶ Secure the system against unintentional activation.

▶ Ensure a controlled restart after maintenance is completed.

6.2 Faults

Check in case of faults:

• Port connections

• Operating pressure

• Operating voltage and valve control

If the valve still does not actuate, please contact your local Bürkert

branch.

English

Loading...

Loading...